Modular combined wardrobe

A modular and combined cabinet technology, applied in the field of furniture, can solve the problems of large cabinet width, unfavorable standardized production, and inability to place it, so as to improve work efficiency and benefit, facilitate standardized production, and have a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0025] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is further described:

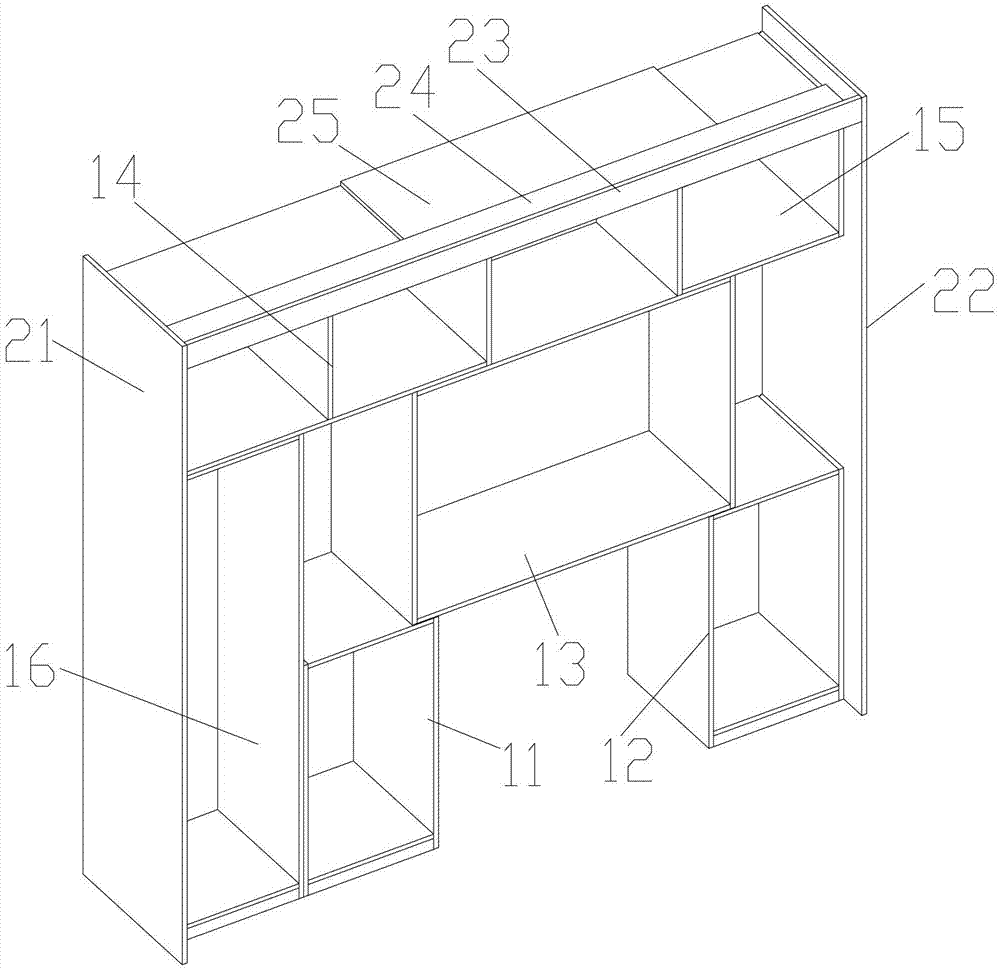

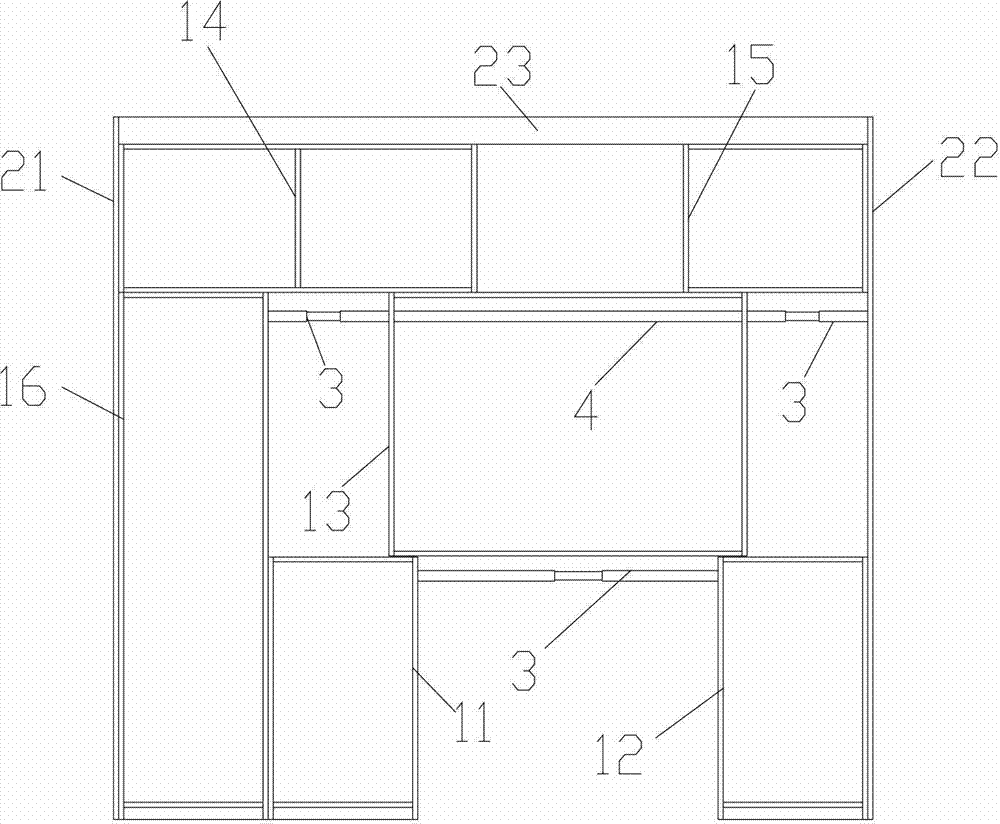

[0026] refer to Figure 1-Figure 3 , a modular combination wardrobe described in this embodiment, which includes a combination cabinet body composed of a plurality of mutually independent modular cabinet bodies, and a fixing assembly for fixing the combination cabinet body;

[0027] The combined cabinet body includes a first bottom cabinet 11, a second bottom cabinet 12, a middle cabinet 13, a first top cabinet 14, a second top cabinet 15 and a first side cabinet 16; two bottom cabinets (11, 12) There is an interval between them, the middle cabinet 13 is set across two bottom cabinets (11, 12), and the left and right sides of the middle cabinet 13 are respectively provided with intervals; the two top cabinets (14, 15) are respectively arranged in the middle On the top surface of the cabinet 13, there is an interval between the two top cabinets (14, 15)...

specific Embodiment 2

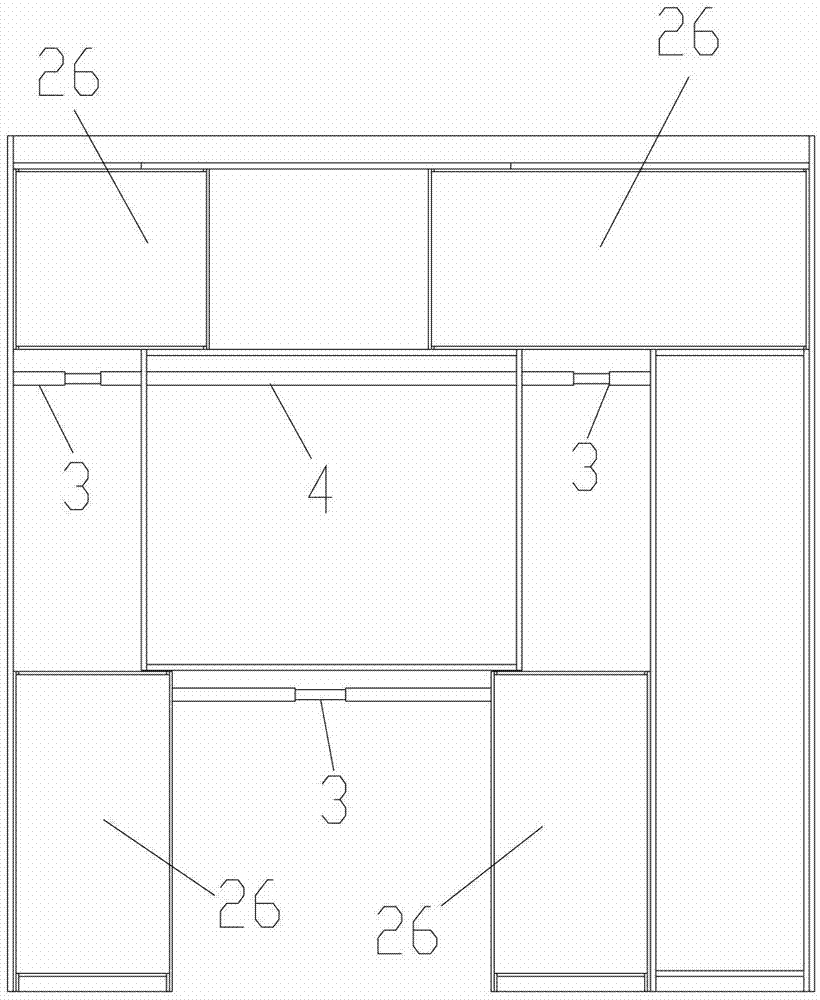

[0032] refer to Figure 4 , the characteristics of this embodiment are: the combined cabinet body also includes a second side cabinet 17, the second side cabinet 17 is located between the second bottom cabinet 12 and the second high side plate 22, the second side cabinet 17 They are fixedly connected with the second bottom cabinet 12 and the second high side plate 22 respectively. The height of the second side cabinet 17 is equal to the sum of the height of the bottom cabinet and the height of the middle cabinet. The second side cabinet 17 supports the second top cabinet 15, increasing the stability of the cabinet. Two side cabinets are set at the same time, which further increases the stability of the cabinet.

[0033] In practical application, the combination cabinet described in this embodiment can be applied to a field width of 2700-3150 mm; it is known that the width W1 of the first high side panel 21 and the second high side panel is 25 mm, and the width W1 of the firs...

specific Embodiment 3

[0035] The characteristics of this embodiment are: the top surfaces of the two bottom cabinets (11, 12) are respectively provided with chute, corresponding to it, the bottom surface of the middle cabinet 13 is provided with a slide rail matching the chute; The bottom surface of the top cabinet (14, 15) is provided with a chute respectively, and correspondingly, a slide rail matching with the chute is provided on the top surface of the middle cabinet 13; (11,12), two top cabinets (14,15) sliding connection. Sliding fit connection is adopted, which makes it more convenient for the middle cabinet to move along the width direction. Others are identical with specific embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com