Unilateral diffusion and beveled flip bucket combined energy dissipation facility

An oblique cutting and unilateral technology, applied in dikes, dams, sea area projects, etc., can solve the problems of increasing the depth of scour pits in the downstream riverbed, severe turbulent amplitude of downstream water flow, and ineffective energy dissipation in the air, etc., so as to achieve reasonable force , reduce the protective work, the effect of simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

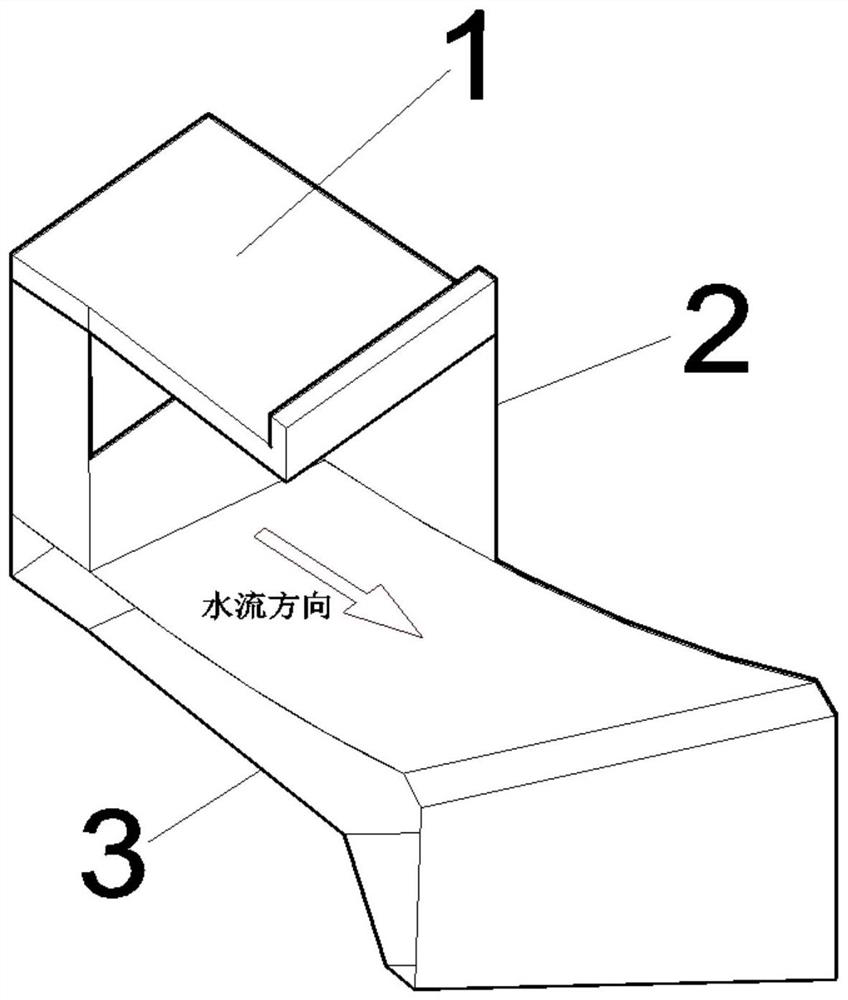

[0031] like figure 1 As shown, the energy-dissipating facility combined with unilateral diffusion and obliquely cut ridges of the present invention includes a ridge top wall 1 , a ridge guide wall 2 , and a ridge base 3 .

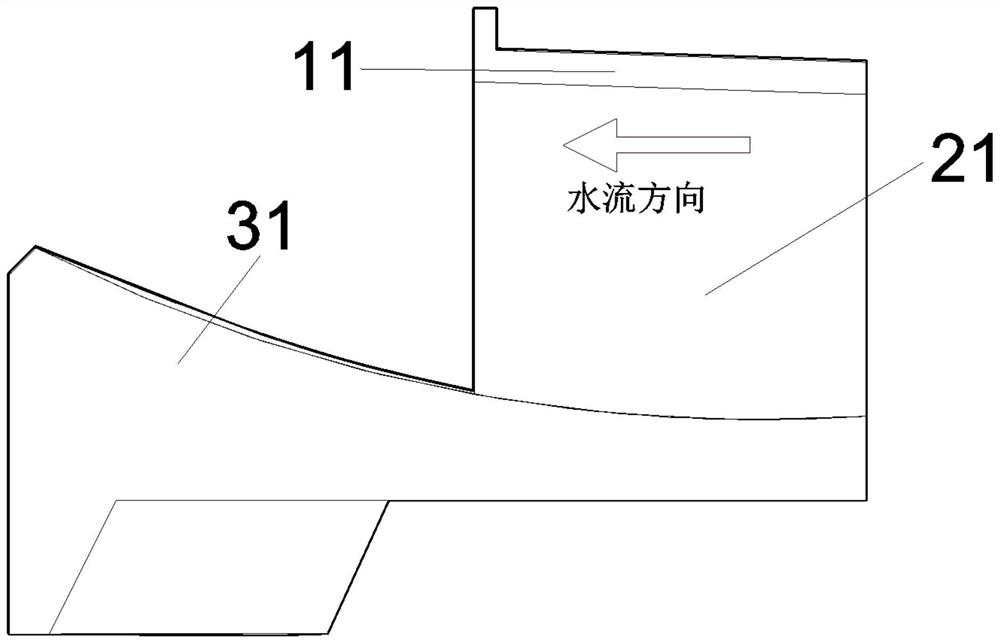

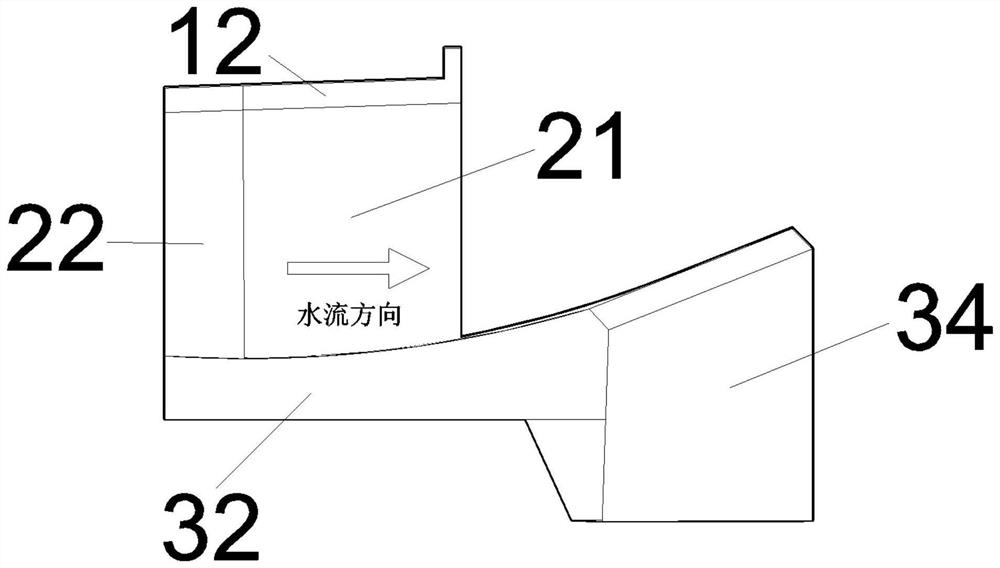

[0032] Figure 2 to Figure 7 As shown, the energy-dissipating facilities combined with unilateral diffusion and obliquely cut ridges in this example include a ridge top wall 1 (top wall left side 11, top wall right side 12), two ridge guide walls 2 ( Left pick ridge guide wall 21, right pick ridge guide wall 22) and a pick ridge pedestal 3 (lift ridge base left side 31, pick ridge base right side 32, pick flow nose sill 33; pick ridge base Exit 34), the arc radius of the nose sill is 60m, the angle from the upstream end to the lowest point L of the arc is 3.762°, and the length L of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com