Method for controlling carbon emission in metallurgical industry

A carbon emission and industry technology, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problem of difficulty in generating high added value, achieve the effect of astonishing cost and solve CO2 emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

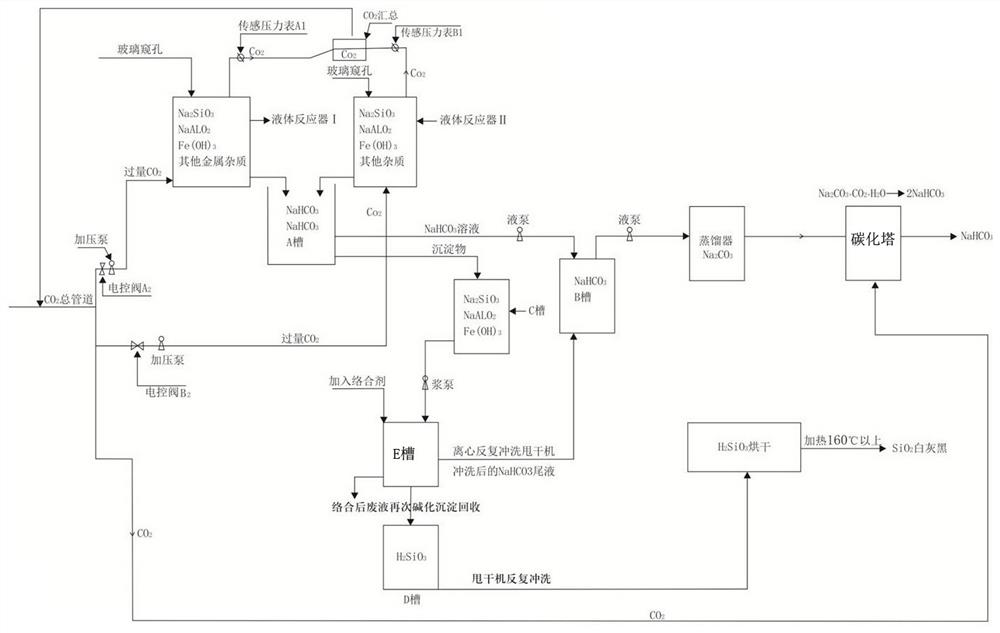

[0022] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

[0023] A method of controlling carbon emissions in the metallurgical industry, converting CO 2 Immersed in an alkaline solution and undergoes an acidic neutralization reaction with soluble alkaline substances to produce a high value-added acidic precipitate; the neutralization reaction condition is that the acidic precipitate produced by the reaction is less than CO 2 dissolved in the reaction solution to produce H 2 CO 3 acidic.

[0024] The soluble alkaline substance is Na 2 SiO 3 The solution is sodium metasilicate, also known as water glass; its reaction equation is:

[0025] CO 2 +Na 2 SiO 3 +H 2 O→Na 2 CO 3 +H 2 SO 3 ↓

[0026] H 2 SiO 3 SiO can be obtained by heating above 160°C 2 White carbon black is a high value-added end product; the reaction formula is H 2 SiO 3 → SiO 2 +H 2 O; SiO 2 The downstream market of whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com