Laser power meter

A laser power meter and absorber technology, applied in the field of laser radiation parameter measurement, can solve the problems of uneven distribution of laser power density, prone to temperature drift, slow response of power meter, etc., to improve laser damage threshold and reduce laser power density , the effect of improving the response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the embodiments in the accompanying drawings.

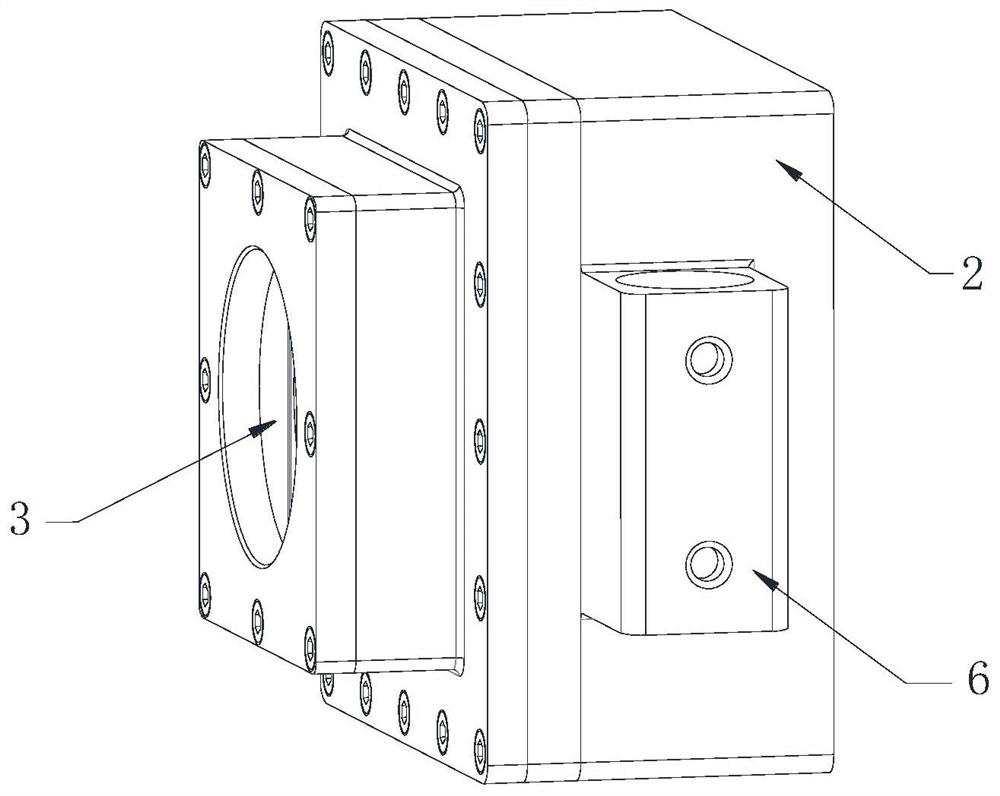

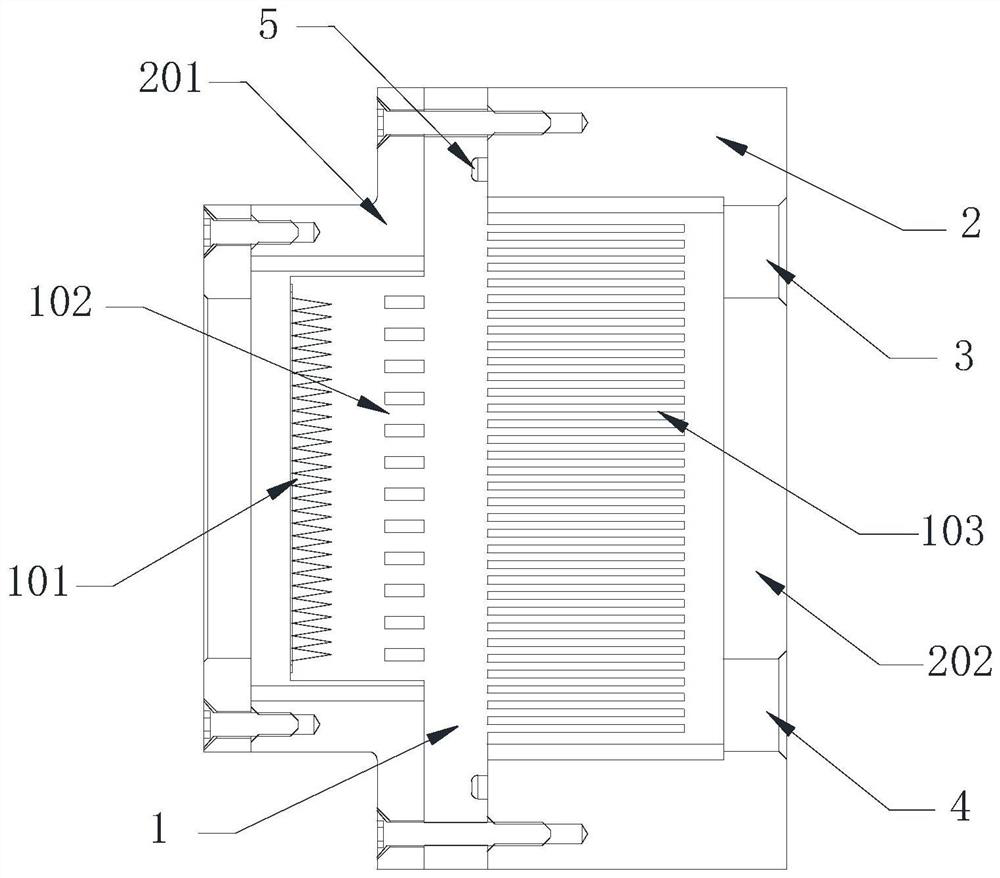

[0023] refer to Figure 1~4 As shown, a laser power meter in this embodiment mainly includes an absorber 1 and a housing 2 . The absorber 1 is placed inside the shell 2, and the two are fixed together by screws.

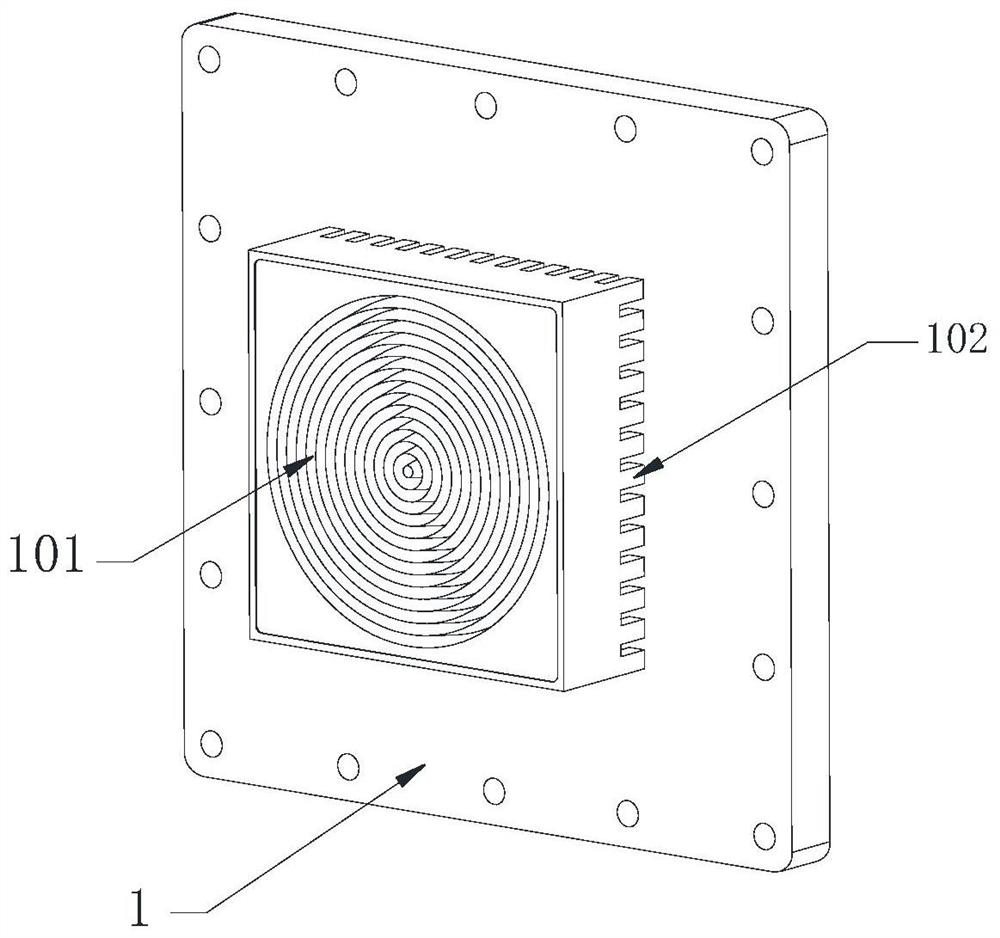

[0024] The absorber 1 is the core component of the laser power meter, which is made of a whole piece of pure copper, and includes key functional modules such as the absorbing target surface 101 , the flow guide component 102 and the heat dissipation component 103 .

[0025] The front end of the absorber 1 is an absorbing target surface 101 for absorbing the energy of incident laser light and converting it into heat energy. In order to improve the absorption rate of incident laser light, the absorption target surface 101 is processed into a V-shaped annular groove structure with a sharp bottom, and a surface treatment process is adopted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com