Aluminum alloy composite seawater concrete column with CFRP attached inside

A technology of concrete columns and aluminum alloys, applied in the directions of columns, piers, pillars, etc., can solve the problems of steel pipe corrosion, high chloride and sulfate content, and achieve the effects of improving bearing capacity, high tensile strength, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

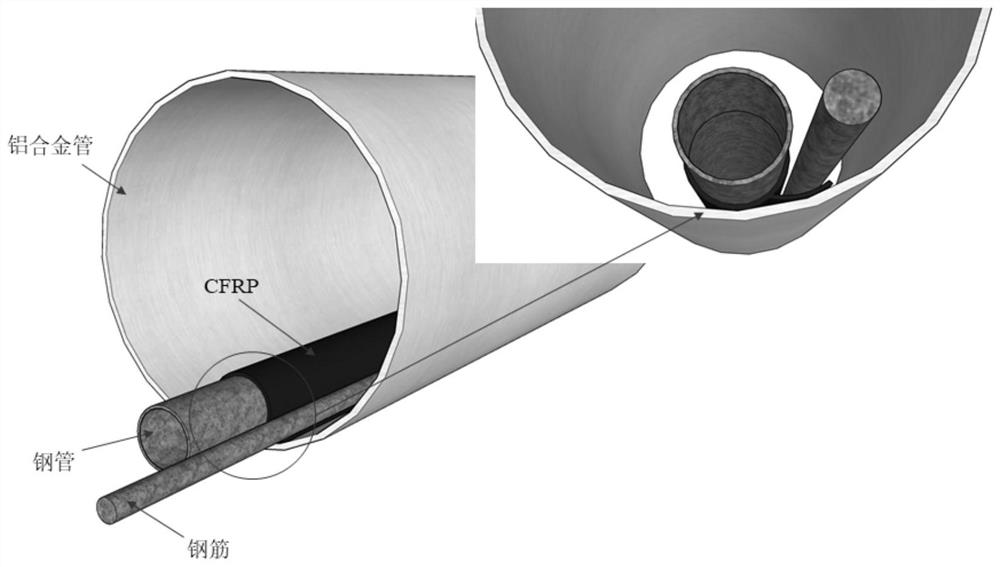

[0030] An aluminum alloy composite seawater concrete column pasted with CFRP, such as figure 1 As shown, it is composed of seawater concrete, aluminum alloy pipe and CFRP cloth; the CFRP cloth is pasted on the inner wall of the aluminum alloy pipe to form a CFRP-aluminum alloy composite pipe, and the seawater concrete is filled in the CFRP-aluminum alloy composite pipe.

[0031] The composition ratio of the seawater concrete of the present embodiment is as follows: ordinary portland cement 487kg / m with a cement strength grade of 42.5 3 , sand 533kg / m 3 , Stone 1245kg / m 3 , Seawater 201kg / m 3 The sand is sea sand, specifically medium sand with a fineness modulus of 2.71; the stone is gravel with a particle size of 5 to 31 mm; the above components are stirred and mixed uniformly to obtain seawater concrete, and the seawater concrete The strength class is C40.

[0032] The aluminum alloy circular tube in this embodiment has a height of 600 mm, a diameter of 150 mm, and a wall...

Embodiment 2

[0041] The manufacturing method of the aluminum alloy composite seawater concrete column pasted with CFRP in this embodiment is the same as that in Example 1, and the composition ratio of the seawater concrete is as follows: Ordinary Portland cement with a cement strength grade of 42.5 480kg / m 3 , sand 530kg / m 3 , stone 1200kg / m 3 , Seawater 190kg / m 3 . The sand is sea sand, specifically medium sand with a fineness modulus of 2.71; the stone is gravel with a particle size of 5-31 mm; the above components are stirred and mixed uniformly to prepare seawater concrete.

Embodiment 3

[0043] The manufacturing method of the aluminum alloy composite seawater concrete column pasted with CFRP in this embodiment is the same as that in Example 1, and the composition ratio of the seawater concrete is as follows: Ordinary Portland cement with a cement strength grade of 42.5 490kg / m 3 , sand 540kg / m 3 , stone 1400kg / m 3 , Seawater 210kg / m 3 . The sand is sea sand, specifically medium sand with a fineness modulus of 2.71; the stone is gravel with a particle size of 5-31 mm; the above components are stirred and mixed uniformly to prepare seawater concrete.

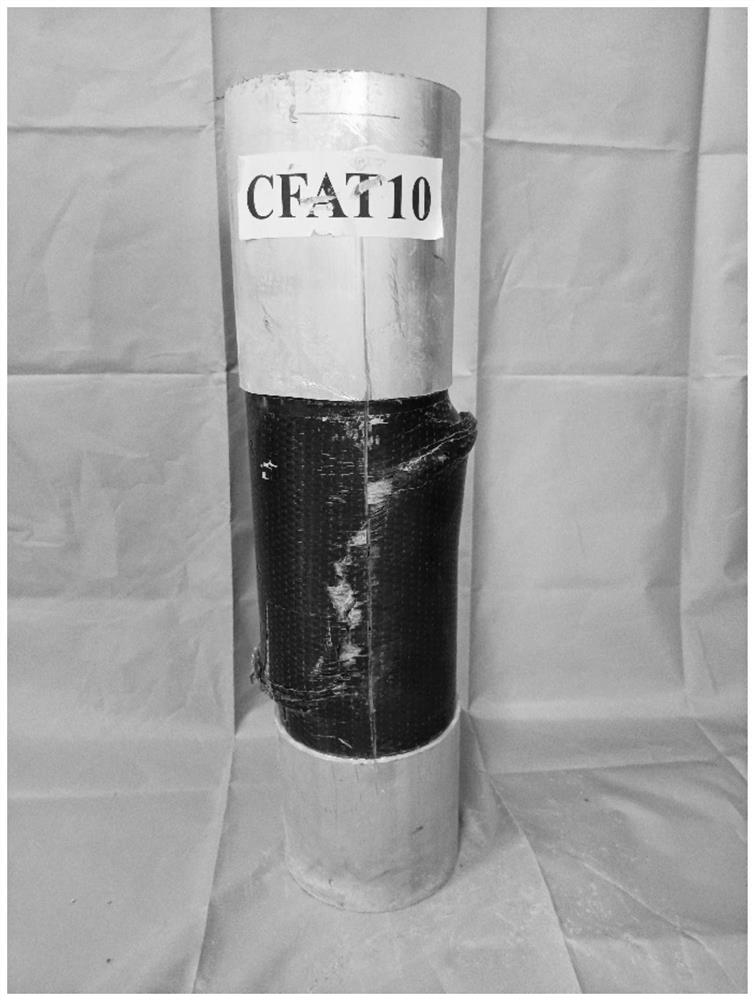

[0044] Effect verification

[0045] In order to further illustrate that the aluminum alloy composite seawater concrete column pasted with CFRP of the present invention has mechanical performance characteristics such as high bearing capacity, the aluminum alloy composite seawater concrete column specimen with CFRP pasted inside prepared in Example 1 was subjected to an axial compression test, and the axial compr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com