Monocrystal ternary positive electrode material and preparation method thereof

A positive electrode material and single crystal technology, which is applied in the field of single crystal nickel-cobalt-manganese ternary positive electrode material and its preparation, can solve the problem of poor ion conductivity and electronic conductivity of materials, difficulty in delithiation of positive electrode materials, and easy formation of aggregates Morphology and other problems, to achieve the effect of reducing the conventional sintering temperature, improving the product rate performance, and increasing the energy density of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

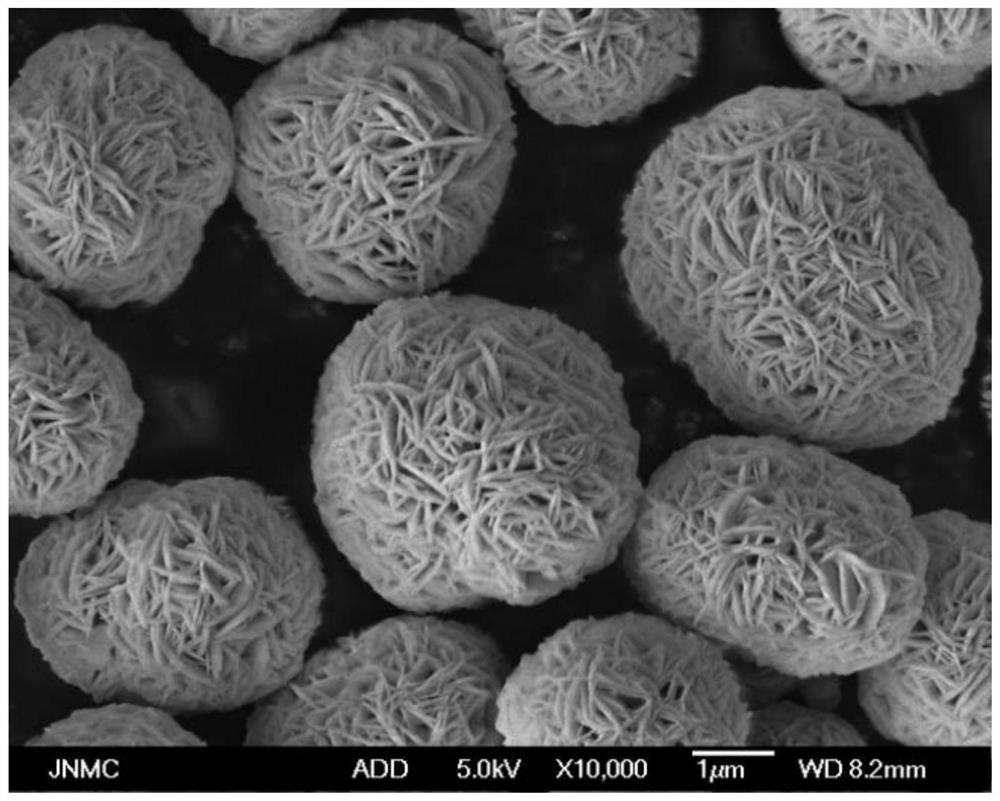

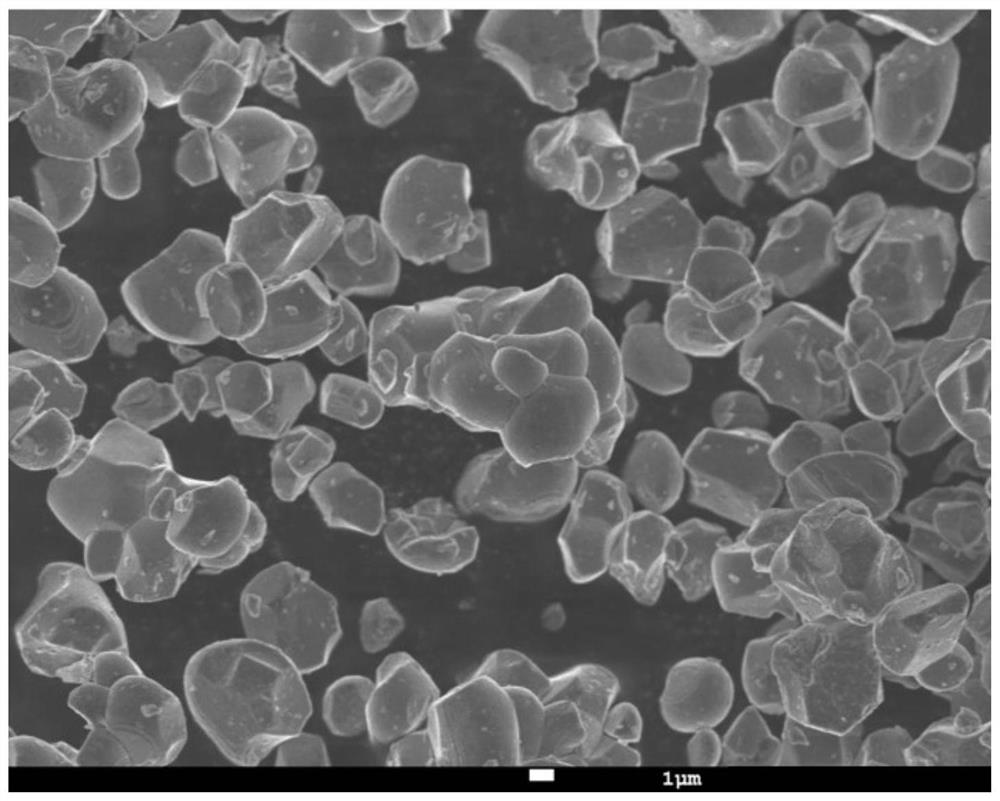

[0060] First, the nickel-cobalt-manganese molar ratio is selected as 55:5:40, the shape is a hollowed-out spherical shape, and the D50 is 3.8 microns. 0.55 co 0.05 mn 0.40 (OH) 2 ,Such as figure 1 shown. Uniformly mixed with lithium hydroxide, wherein the molar ratio of lithium to transition metal is 1.02, the mixed powder is sintered in the air atmosphere, the sintering temperature is 860 °C, and the 12h heat preservation sintering is completed, and finally the ternary cathode material Li 1.02 Ni 0.55 co 0.05 mn 0.40 o 2 . (Such as figure 2 shown)

[0061] Then, through mechanical fine crushing, the D50 is controlled to be about 4.0 microns, and uniformly mixed with lithium carbonate and zirconia. The amount of zirconia is calculated based on the mass of zirconium element, and the ratio of element addition to the total moles of transition metals in the precursor is 4:1000; the molar ratio of lithium to transition metals is 0.12; the mixed powder is sintered in an ...

Embodiment 2

[0066] First, the nickel-cobalt-manganese molar ratio is 55:05:40, the precursor Ni is loose and porous, and the D50 is 3.8 microns. 0.55 co 0.05 mn 0.40 (OH) 2 . Uniformly mixed with lithium carbonate, wherein the molar ratio of lithium to transition metal is 1.04, the mixed powder is sintered in the air atmosphere, the sintering temperature is 880°C, and the 15h heat preservation sintering is completed, and finally the ternary cathode material Li 1.04 Ni 0.55 co 0.05 mn 0.40 o 2 .

[0067] Then, after mechanical fine crushing, the D50 is controlled to be about 4.0 microns, and it is uniformly mixed with lithium hydroxide and zirconia. The amount of zirconia is calculated by the mass of zirconium element. The ratio is 4:1000; the molar ratio of lithium to transition metal is 0.12; the mixed powder is sintered in an air atmosphere, and the high-temperature sintering temperature is increased to 960°C, and the 20h heat preservation sintering is completed, and finally the...

Embodiment 3

[0071] First, the nickel-cobalt-manganese molar ratio is 55:05:40, the precursor Ni is loose and porous, and the D50 is 3.8 microns. 0.55 co 0.05 mn 0.40 (OH) 2 . Uniformly mixed with lithium hydroxide, wherein the molar ratio of lithium to transition metal is 1.02, the mixed powder is sintered in the air atmosphere, the sintering temperature is 850°C, and the sintering is completed for 12 hours, and finally the ternary cathode material Li 1.02 Ni 0.55 co 0.05 mn 0.40 o 2 .

[0072] Then, after mechanical fine crushing, the D50 is controlled to be about 4.0 microns, and uniformly mixed with lithium acetate and lanthanum oxide. The amount of lanthanum oxide is calculated by the mass of lanthanum element, and the ratio of the amount of elements added to the total moles of transition metals in the precursor is the molar ratio. 3:1000; the molar ratio of lithium to transition metal is 0.10; the mixed powder is sintered in an air atmosphere, and the high-temperature sinteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com