A kind of preparation method of micro-nano metal particle surface coating

A metal particle, micro-nano technology, applied in the field of surface engineering, can solve the problems of growing on the cathode and difficult to form a coating, and achieve the effects of high material utilization, good high temperature performance and high electroplating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0029] Embodiment 1: This embodiment describes a method for preparing a coating on the surface of micro-nano metal particles. The specific steps of the method are as follows:

[0030] Step 1: Select the micro-nano metal particles to be electroplated, and remove the oxide film on the surface;

[0031] Step 2: Select and configure the plating solution to be electroplated, select and make the electrode for electroplating;

[0032] Step 3: mixing the micro-nano metal particles obtained in step 1 with the plating solution in step 2 to prevent the micro-nano metal particles from being oxidized in the air;

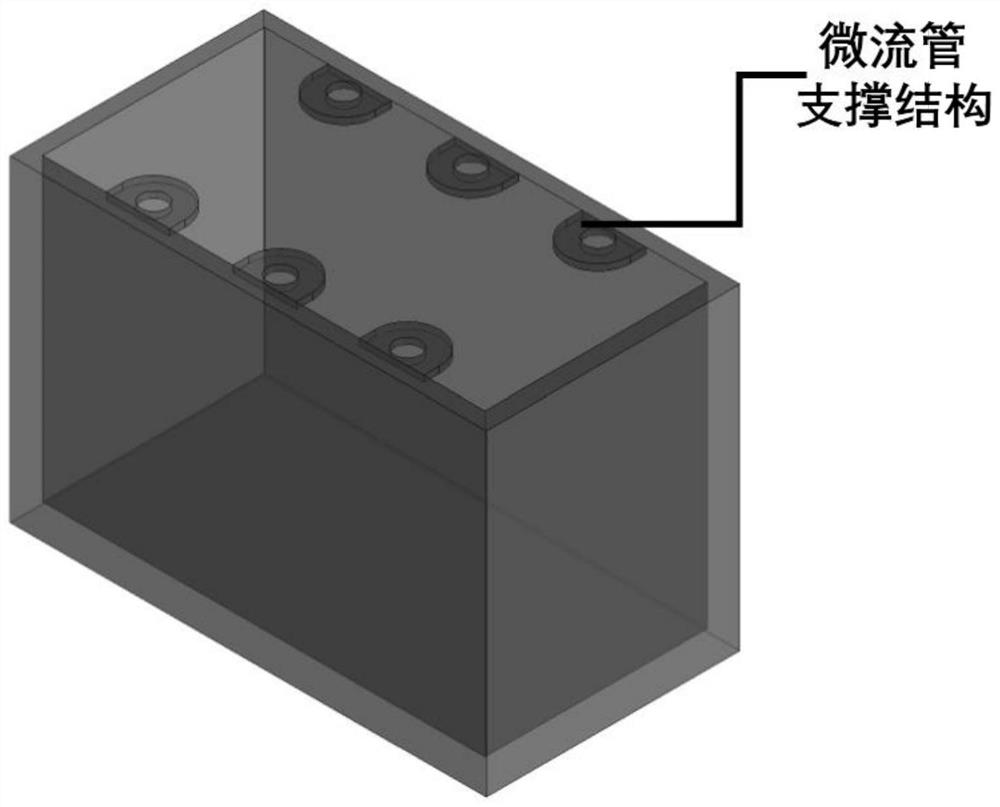

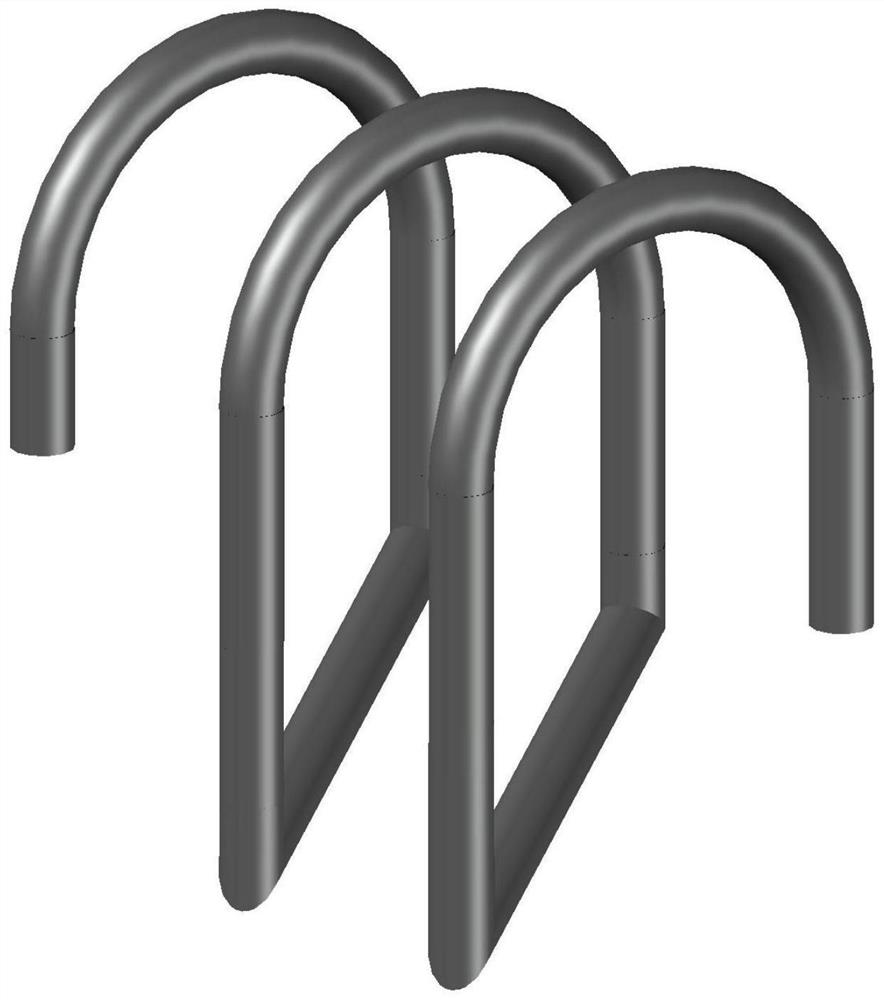

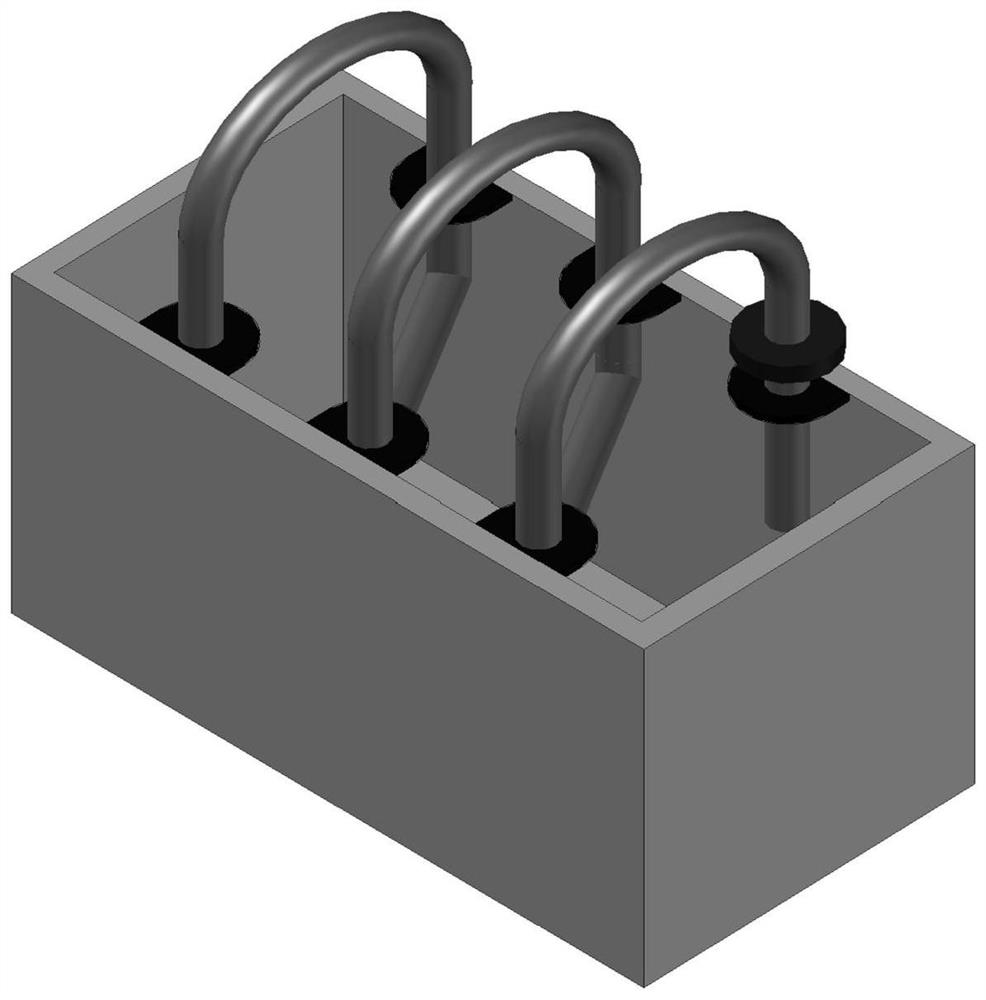

[0033] Step 4: Assemble an electroplating device, the electroplating device specifically includes an electroplating tank, a microfluidic tube, a micropump and a power supply; the microfluidic tube includes a vertical section and a transition section, such as figure 2 The vertical section is equipped with a plurality of pairs of electrodes for electroplating and the lead wires o...

specific Embodiment approach 2

[0042] Embodiment 2: In the method for preparing the surface coating of micro-nano metal particles described in Embodiment 1, in step 1, the micro-nano metal particles to be electroplated are spherical particles with a diameter of 50 nm to 10 μm, and the material is Copper and other micro-nano metal particles with good electrical conductivity.

specific Embodiment approach 3

[0043] Embodiment 3: In the method for preparing a coating on the surface of micro-nano metal particles described in Embodiment 1, during the circulation process of the plating solution, it is necessary to ensure that the plating solution is kept in a continuous state without bubbles in the microfluidic tube.

[0044] Embodiment 4: The method for preparing a coating on the surface of micro-nano metal particles described in Embodiment 1. In step 8, the flow rate of the plating solution in the microfluidic tube is 0.1 m / s. The nano-metal particles stay in the cathode for a short time to complete the electroplating, and due to the scouring of the water flow, the micro-nano metal particles will not grow on the surface of the cathode and enter the plating solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com