High-strength low-chroma polyether-ether-ketone and preparation method thereof

A technology of polyether ether ketone and pressure, which is applied in the field of engineering plastics, can solve the problems of complex polyetheretherketone process, undiscovered, and many influencing factors, and achieve the effects of shortening the reaction time, brightening the color, and reducing the reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

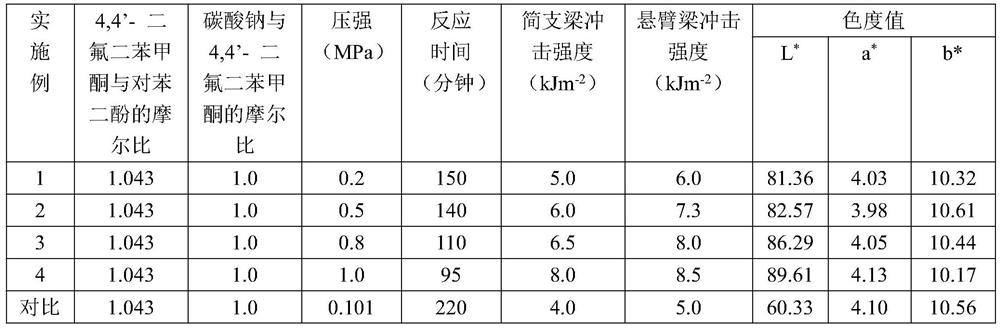

Examples

preparation example Construction

[0028] A kind of preparation method of polyether ether ketone provided by the invention comprises the following steps:

[0029] Under the pressure of 0.15MPa~1.0MPa in an inert atmosphere, the first polymerized monomer and the second polymerized monomer undergo a nucleophilic polycondensation reaction in an inert aprotic solvent in the presence of alkali metal carbonate to obtain polyether ether ketone;

[0030] The first polymerizable monomer is hydroquinone, biphenol, 4,4'-dihydroxybenzophenone, 2,2-bis(4-hydroxyphenyl)propane, 1,3-bis- Any one or more of (p-hydroxybenzoyl)benzene, 1,4-bis-(p-hydroxybenzoyl)benzene, α-naphthol and β-naphthol;

[0031] The second polymerizable monomer is 4,4'-difluorobenzophenone, 2,4'-difluorobenzophenone, 4-fluoro-4'-chloro-benzophenone, 2-fluoro- 4'-chloro-benzophenone, 2-chloro-4'-fluoro-benzophenone, diphenyl ether, 4,4'-diphenoxybenzophenone, terephthaloyl chloride and isophthalic acid Any one or more of diformyl chlorides.

Embodiment 1

[0035] Add 530.54g of diphenyl sulfone, 110.10g of 4,4'-difluorobenzophenone, 60.71g of sodium carbonate, 53.22g of hydroquinone into the French mechanically stirred autoclave, Pure nitrogen, after repeating three times, completely replace the air in the system with nitrogen, then start to pressurize to 0.2MPa, heat to melt, start stirring to 100rpm / min, raise the temperature to 160°C for 30 minutes, continue heating to 200°C for 30 minutes , the temperature is raised to 260°C, and the reaction is performed at a constant temperature until the viscosity of the reaction system reaches 410Pa.s, and the reaction process is monitored through the viscosity; the viscosity reaches the detection value, and the degree of polymerization of the molecules meets the requirements. At this time, the reaction time is 90 minutes. Pour the material into cold distilled water to obtain a white lump, crush the white lump with a pulverizer, wash with ethanol for 5 to 6 times to remove the solvent dip...

Embodiment 2

[0037]Add 780.63g of diphenyl sulfone, 176.16g of 4,4'-difluorobenzophenone, 97.13g of sodium carbonate, 85.15g of hydroquinone into the French mechanically stirred autoclave, Pure nitrogen, after repeating three times, completely replace the air in the system with nitrogen, then start to pressurize to 0.5MPa, heat to melt, start stirring to 100rpm / min, heat up to 160°C for 30 minutes, continue heating to 200°C for 30 minutes , heat up to 250°C, and react at a constant temperature until the viscosity of the reaction system reaches 410Pa.s. At this time, the reaction time is 80 minutes. Pour the material into cold distilled water to obtain a white block. Use a pulverizer to crush the white block. Wash with ethanol for 5 to 6 times to remove the solvent diphenyl sulfone, wash with distilled water for 5 to 6 times to remove the inorganic salts generated by the reaction, and obtain a white powder, prepare a standard sample with a small injection molding machine, and test the chroma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com