Treatment method of high-concentration ethylene amine wastewater

A treatment method and technology for wastewater treatment, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., to achieve the effects of simple process, easy operation and low investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

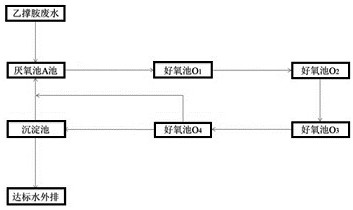

Image

Examples

Embodiment 1

[0040] 1. Early stage: sludge inoculation

[0041] Add water to the anaerobic pool A pool and the aerobic pool O1-O4 pool until the water comes out of the O4 pool. Turn on all propellers in the anaerobic tank to stir, turn on one fan in the aerobic tank for aeration, open the O4 tank to strip air from the return pipe of the anaerobic tank, and establish a water return between the aerobic tank and the anaerobic tank, so that the water in the Cycle between anaerobic pool and aerobic pool O1-O4. Control the water temperature at 20-25°C, add sewage treatment activated sludge to the anaerobic tank, and carry out bacterial inoculation. When the activated sludge content mlvss reaches 2-3g / L, the sludge addition ends. After the sludge dosing is completed, keep the fan in the aerobic pool running for 24 hours. Add wastewater containing ammonia, methanol, and phosphorus to the anaerobic pool A after the stuffy exposure, supplement nitrogen sources, carbon sources, and phosphorus sour...

Embodiment 2

[0054] 1. Early stage: sludge inoculation

[0055] Add water to the anaerobic pool A pool and the aerobic pool O1-O4 pool until the water comes out of the O4 pool. Turn on all propellers in the anaerobic tank to stir, turn on one fan in the aerobic tank for aeration, open the O4 tank to strip air from the return pipe of the anaerobic tank, and establish a water return between the aerobic tank and the anaerobic tank, so that the water in the Cycle between anaerobic pool and aerobic pool O1-O4. Control the water temperature at 25-30°C, add sewage treatment activated sludge to the anaerobic tank, and carry out bacterial inoculation. When the activated sludge content mlvss reaches 3-4g / L, the sludge addition ends. After the sludge dosing is completed, keep the fan in the aerobic pool running for 24 hours. After the stuffy exposure is over, add wastewater containing ammonia, methanol, and phosphorus to the anaerobic pool A, supplement nitrogen sources, carbon sources, and phosph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com