Plant straw ecological board and preparation method thereof

A plant straw, ecological board technology, applied in the direction of manufacturing tools, flat products, other household appliances, etc., can solve the problems of no competitive advantage, difficult demoulding, prolonged hot pressing time, etc., to improve the comprehensive utilization rate and facilitate industrial production. , The effect of ultra-low VOC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0060] Step 1. Prepare special adhesive for plant straw ecological board

[0061] The raw materials and dosage required to prepare the special adhesive for plant straw ecological board are as follows:

[0062] In parts by weight, 120-130 parts of vegetable glue, 3-4 parts of water-repellent agent, 0.5-1 part of preservative, 0.2-0.3 part of coupling agent, 1.5-2 parts of wetting agent, 0.3-0.5 part of emulsifier, 6-9 parts of composite desiccant.

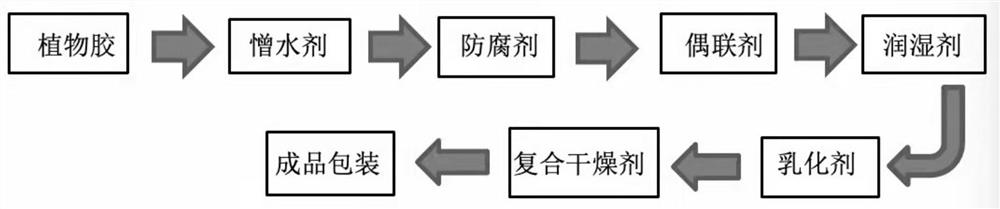

[0063] refer to figure 1 , the technical process of preparing the special adhesive for plant straw ecological board is as follows:

[0064] According to the formula dosage, add the vegetable gum into the dispersing tank with agitator, and add water-repellent agent, preservative, coupling agent, wetting agent, emulsifier and composite desiccant in turn under the stirring condition of rotating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com