Ammonia process desulfurization spraying tower system and method for determining SO2 absorption mass transfer coefficient

A technology of ammonia desulfurization and mass transfer coefficient, which is applied in the field of ammonia desulfurization flue gas, and can solve the problems of accurately reflecting the absorption process of ammonia desulfurization process, loss of ammonia volatility, and inability to truly simulate ammonia desulfurization process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

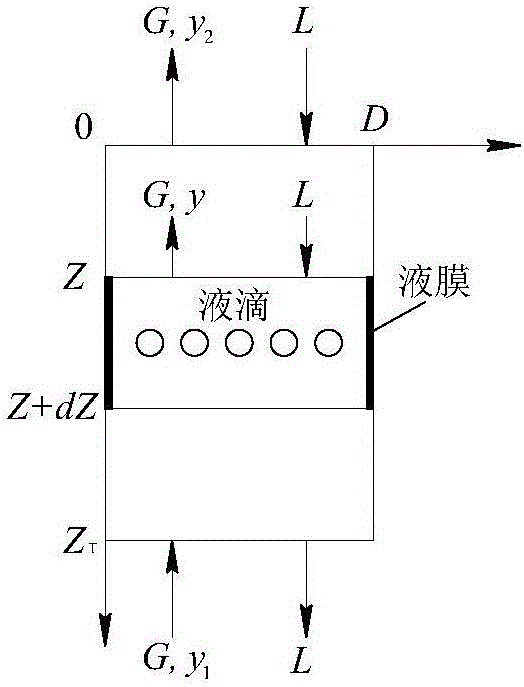

[0078] 1. Ammonia desulfurization SO 2 Determination of absorption mass transfer coefficient

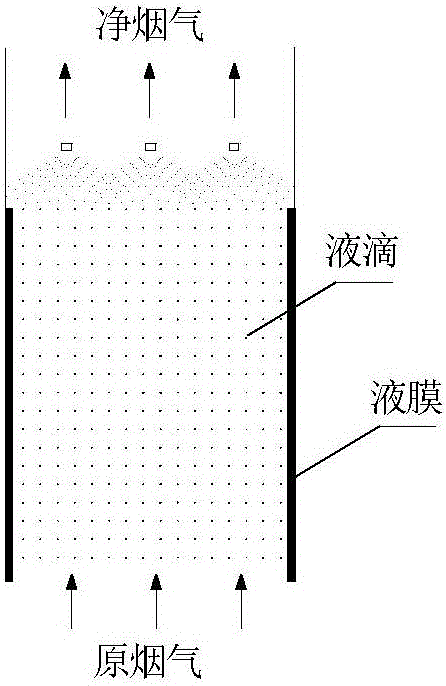

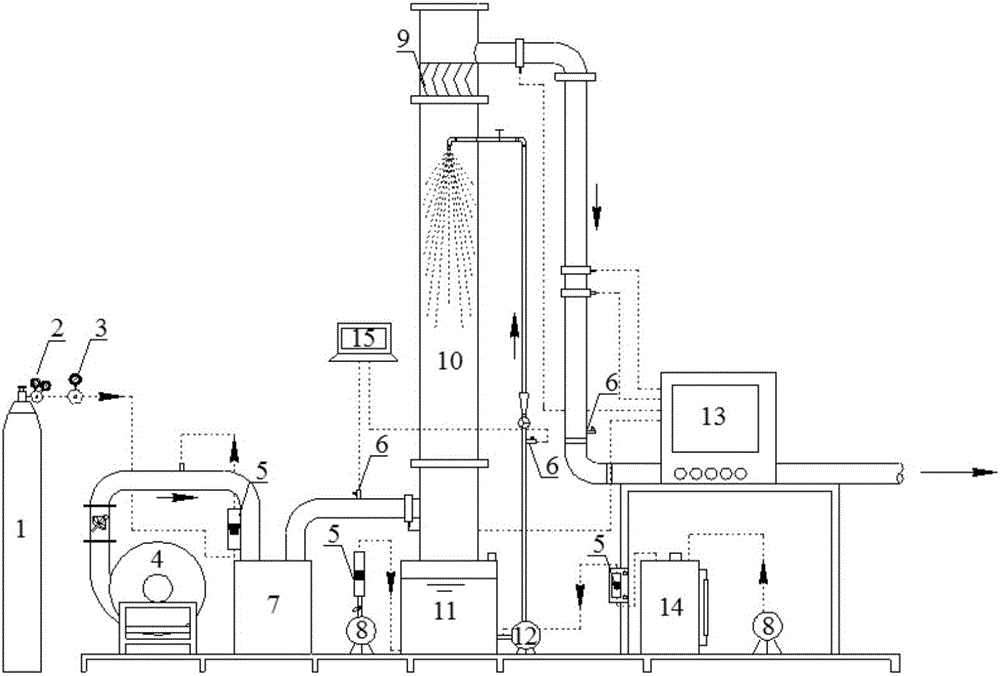

[0079] The ammonia method desulfurization spray tower system of the present embodiment is as figure 1 As shown, the diameter D of the spray tower is 0.3m, and the height Z of the absorption zone is 2.0m. The ammonia desulfurization spray tower system includes a spray tower body 10, the spray tower body 10 includes a demister area, a spray area and a slurry tank 11 from top to bottom, and the demist area is provided with a demister 9, A flue gas outlet is arranged above the demister 9, and the flue gas outlet is connected with the tail gas discharge pipe, and a control cabinet 13 is arranged on the tail gas discharge pipe. The spray area is provided with a spray pipe, and the water inlet of the spray pipe communicates with the bottom of the slurry tank 11 through a circulation pipe and a circulation pump 12 . The bottom of the slurry tank 11 is also connected to the air pump 8 thro...

Embodiment 2

[0155] Using the spray tower ammonia desulfurization experimental system as in Example 1, the pH of the slurry is controlled to be 5.5, and the flue gas flow rate is u g is 3.34m / s, and the liquid-gas ratio is 3L / m 3 , the experimentally measured SO at the inlet of the spray tower 2 Concentration is 360ppm, SO at the outlet of spray tower 2 Concentration is 233ppm, SO calculated by simultaneous formula (3)~(15) 2 The absorption mass transfer coefficient is 3.545kmol / (m 2 h), the calculation method is the same as in Example 1. Set the experimental conditions to pH 5.5, u g is 3.34m / s, and the liquid-gas ratio is 3L / m 3 Substitute into the established ammonia desulfurization SO 2 Mass transfer rate expression, calculated to get SO 2 The absorption mass transfer coefficient is 3.54kmol / (m 2 h), the error between the two is only 0.13%.

Embodiment 3

[0157] Using the spray tower ammonia desulfurization experimental system as in Example 1, the pH of the slurry is controlled to be 5.68, and the flue gas flow rate is u g 2.16m / s, liquid-gas ratio is 3L / m 3 , the experimentally measured SO at the inlet of the spray tower 2 Concentration is 360ppm, SO at the outlet of spray tower 2 The concentration is 183.7ppm, the SO calculated by simultaneous formula (3)~(15) 2 The absorption mass transfer coefficient is 3.75kmol / (m 2 h), the calculation method is the same as in Example 1. Set the experimental conditions to pH 5.68, u g 2.16m / s, liquid-gas ratio is 3L / m 3 Substitute into the established ammonia desulfurization SO 2 Mass transfer rate expression, calculated to get SO 2 The absorption mass transfer coefficient is 3.60kmol / (m 2 • h), the error between the two is 3.94%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com