Internal and external circular air assisted electrospinning nozzle unit

A technology of spinning nozzle and air flow, which is applied in the field of electrostatic spinning nozzle devices assisted by inner and outer double-circle airflow, which can solve the problems of easy blockage of capillary tubes, achieve high spinning efficiency, strong controllability, and reduce the critical voltage value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

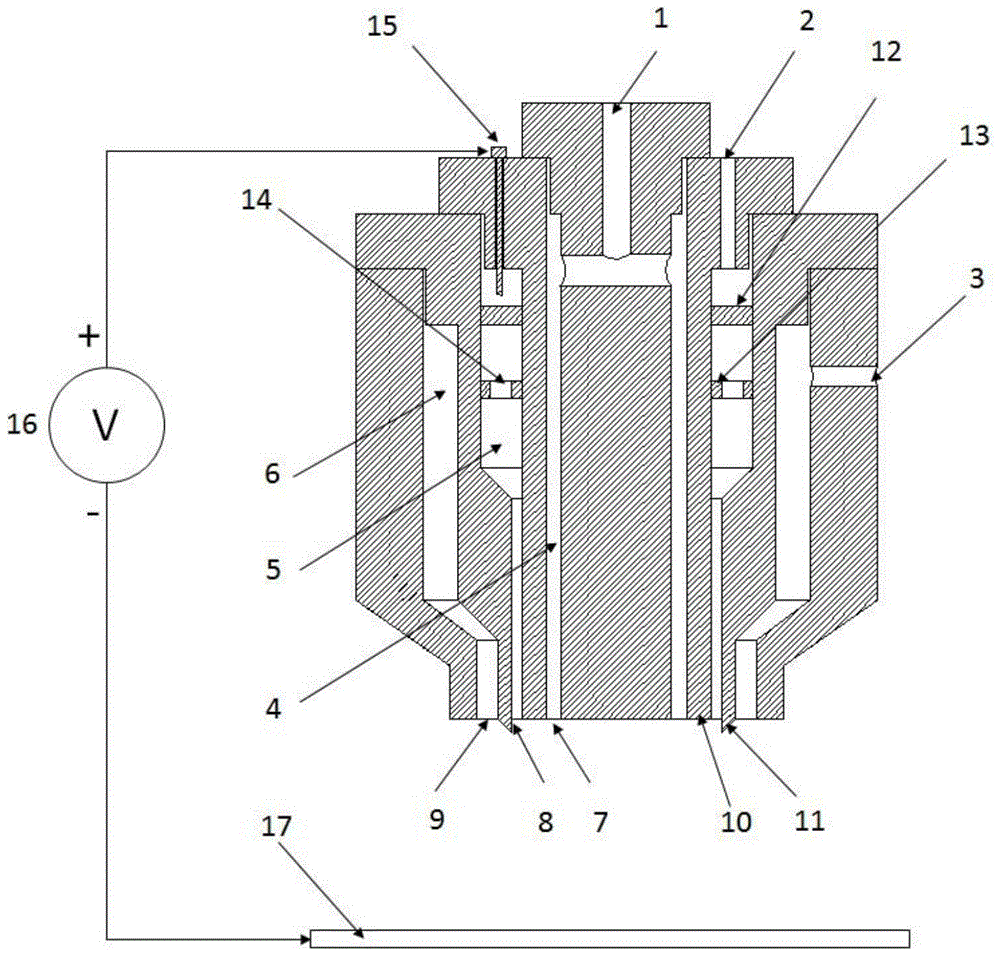

[0033] The schematic diagram of embodiment 1 is as figure 1 Shown, at first, by adding the powder of PVDF in the mixed solvent of acetone and DMF, the PVDF spinning stock solution that concentration is 13%w / v is prepared, and the molecular weight of PVdF is 500,000, and the viscosity range of spinning stock solution is 1200± 50cP.

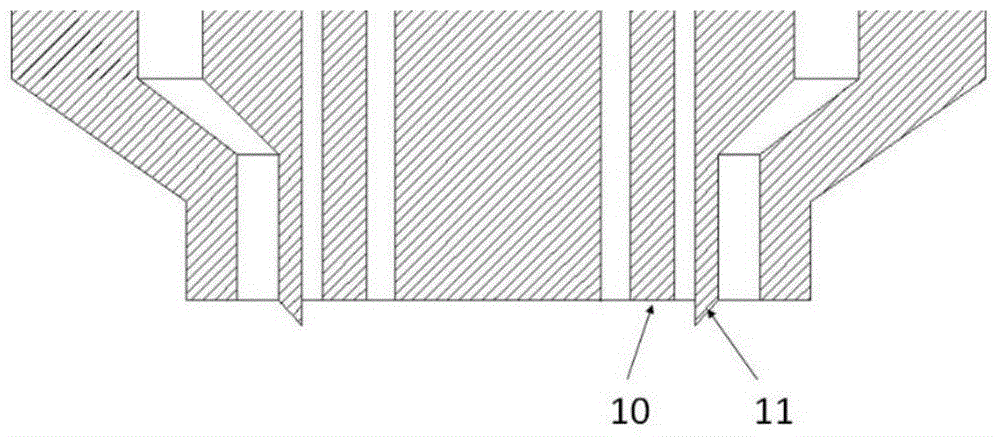

[0034] In this embodiment, the lower end of the third component 103 is longer than the lower end of the second component 102, and has a tapered end structure, that is, the outer wall 11 of the material liquid outlet of the spinning nozzle device is 1.5 mm longer than the inner wall 10 of the material liquid outlet, and For the end cone structure, such as figure 2 As shown, a discharge tip is formed; the receiving electrode 17 is a stainless steel plate, and the surface of the stainless steel plate is wrapped with aluminum foil to facilitate sample collection. First, the positive pole of the high-voltage power supply V is connected to the positive...

Embodiment 2

[0040] The schematic diagram of this embodiment is as figure 1 Shown, at first, by adding the powder of PVDF in the mixed solvent of acetone and DMF, the PVDF spinning stock solution that concentration is 13%w / v is prepared, and the molecular weight of PVdF is 500,000, and the viscosity range of spinning stock solution is 1200± 50cP.

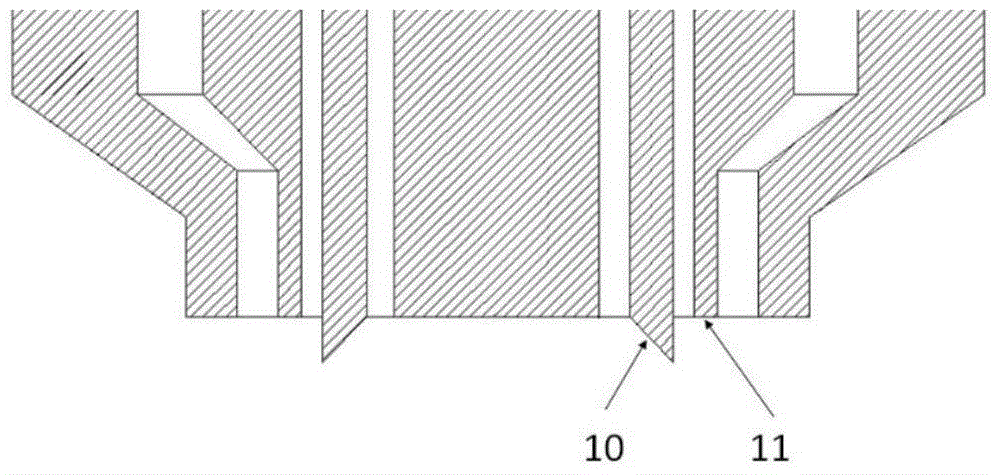

[0041] In this example, if image 3 As shown, the lower end of the second assembly 102 is longer than the lower end of the third assembly 103, and is a tapered end structure, that is, in the case of the spinning nozzle device, the inner wall 10 of the material liquid outlet is 2 mm longer than the outer wall 11 of the material liquid outlet, and the material liquid outlet is 2 mm longer than the outer wall 11 of the material liquid outlet. The inner wall of the liquid outlet is 2mm thick and has a tapered end structure, forming a discharge tip. The receiving electrode 17 is a stainless steel plate, and the surface of the stainless steel plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com