Oxygen-terminated single-layer titanium carbide composite titanium dioxide photocatalyst and preparation method thereof

A titanium dioxide and photocatalyst technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as photogenerated electrons, incomplete separation of holes, weakened redox ability, and inability to obtain activity, etc. , to achieve the effect of inhibiting the recombination of electrons and holes and enhancing the photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a simple and effective preparation method for preparing oxygen-terminated single-layer titanium carbide composite titanium dioxide novel photocatalyst, in order to improve Ti 3 C 2 T x The photocatalytic performance of materials provides a reference method.

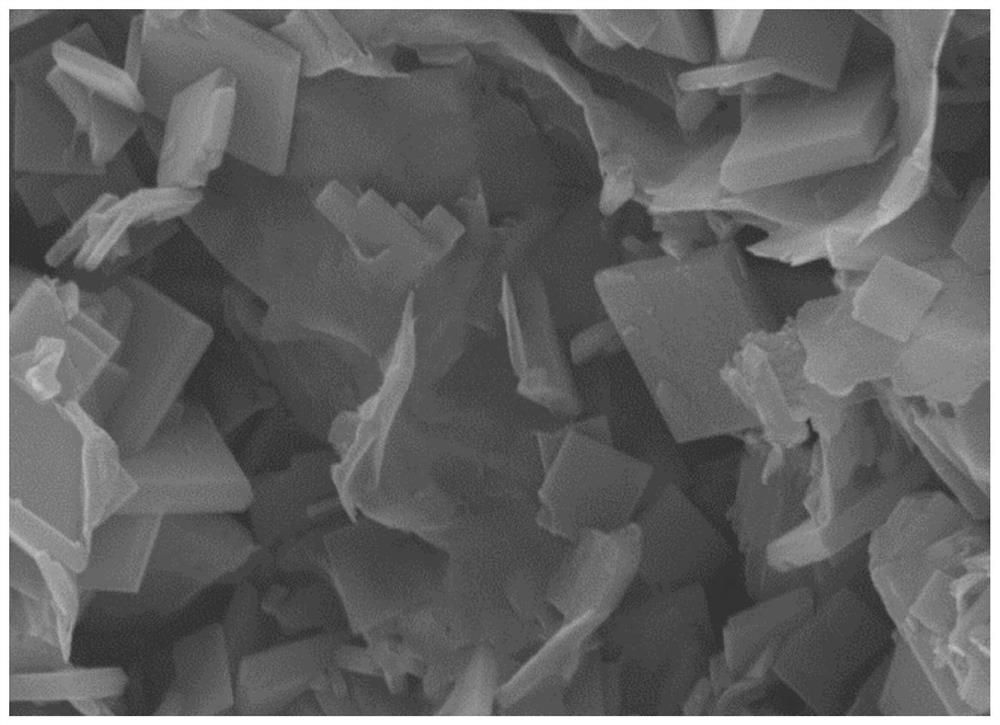

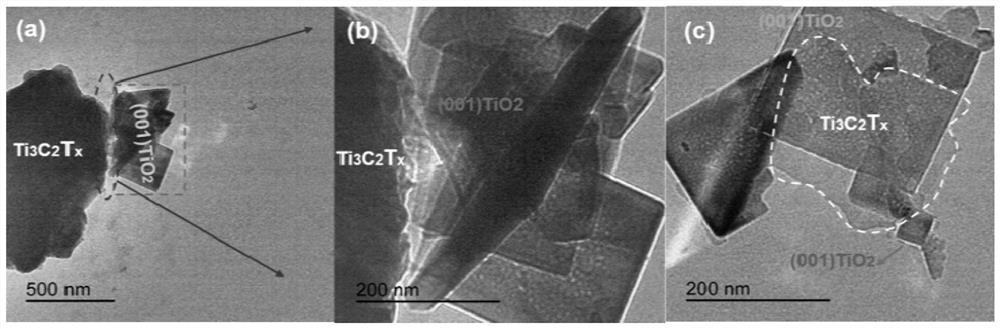

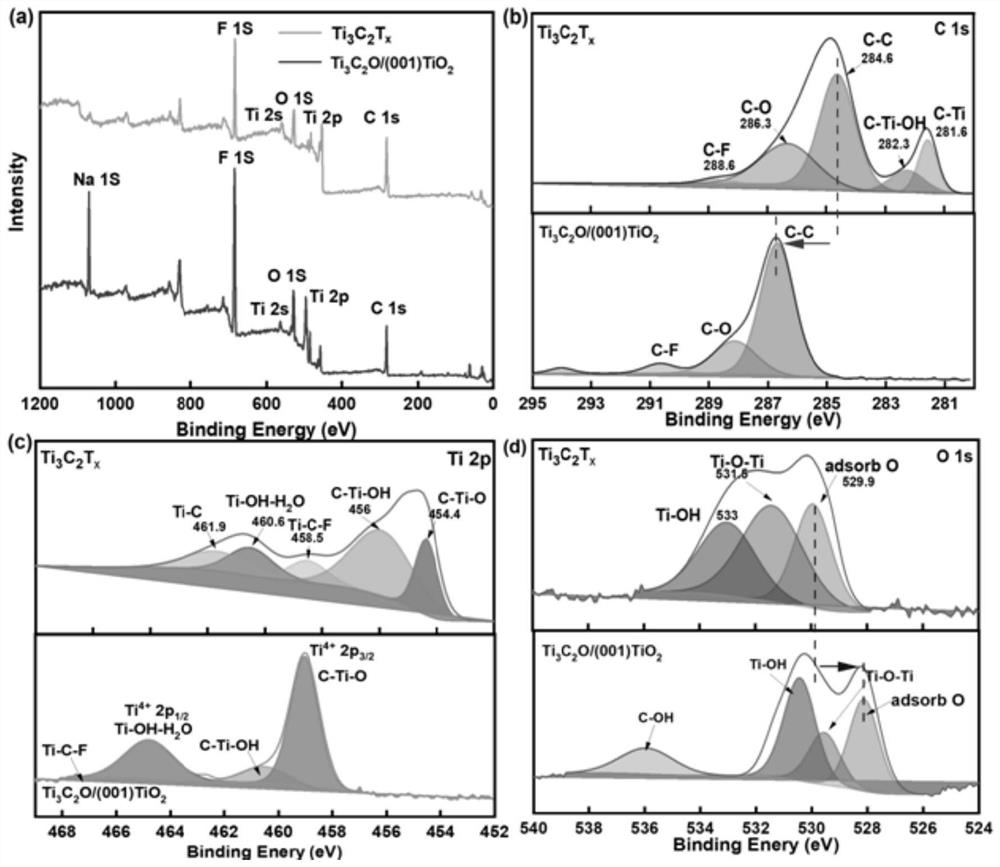

[0030] The oxygen-terminated single-layer titanium carbide composite titanium dioxide photocatalyst of the present invention is composed of an oxygen-terminated single-layer Ti 3 C 2 T x TiO with exposed (001) faces 2 Composition, by in situ hydrothermal oxidation method on monolayer Ti 3 C 2 T x Edge-growth (001) surface exposed TiO 2 , when using muffle furnace annealing to increase Ti 3 C 2 T x content of surface oxygen groups. Improvement of single Ti by triple controllable modification of surface functional groups, exposing highly active faces and controlling structure size 3 C 2 T x photocatalytic ability.

[0031] The steps of the preparation method are:

[0032] (1) T...

Embodiment 1

[0040] Measure 25mL of 9mol / L concentrated hydrochloric acid into a 100mL PTFE container, then weigh 1g of LiF powder and dissolve it in the container, and continue magnetic stirring for 30 minutes. After that, 1g Ti 3 AlC 2 Slowly added to the above solution. Because the addition process will release a lot of heat, in order to prevent Ti 3 AlC 2 was oxidized, and the entire addition process lasted 5 minutes. Ti 3 AlC 2 After adding everything, seal with parafilm. Stirring was continued at 35°C for 36 hours to completely etch away the Al layer. After the etching is completed, centrifuge and wash with ultrapure water for 6-8 times until the supernatant is neutral.

[0041] After the last washing, the product was re-dissolved in 50 mL of ultrapure water, and the ice water was sonicated for 1.5 hours under the protection of argon to separate the layers. After sonication, centrifuge at 3500rpm for 1 hour, collect the dark green suspension in the upper layer, freeze-dry ov...

Embodiment 2

[0045] Measure 50mL of 9mol / L concentrated hydrochloric acid into a 100mL PTFE container, then weigh 2g of LiF powder and dissolve it in the container, and continue magnetic stirring for 30 minutes. After that, add 2g Ti 3 AlC 2 Slowly added to the above solution. Because the addition process will release a lot of heat, in order to prevent Ti 3 AlC 2 was oxidized, and the entire addition process lasted 5 minutes. Ti 3 AlC 2 After adding everything, seal with parafilm. Stirring was continued at 30° C. for 48 hours to completely etch away the Al layer. After the etching is completed, centrifuge and wash with ultrapure water for 6-8 times until the supernatant is neutral.

[0046] After the last washing, the product was re-dissolved in 50 mL of ultrapure water, and the ice water was sonicated for 1.5 hours under the protection of argon to separate the layers. After sonication, centrifuge at 3500rpm for 1 hour, collect the dark green suspension in the upper layer, freeze-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com