CQDs/P photocatalysis composite material and preparation method and application

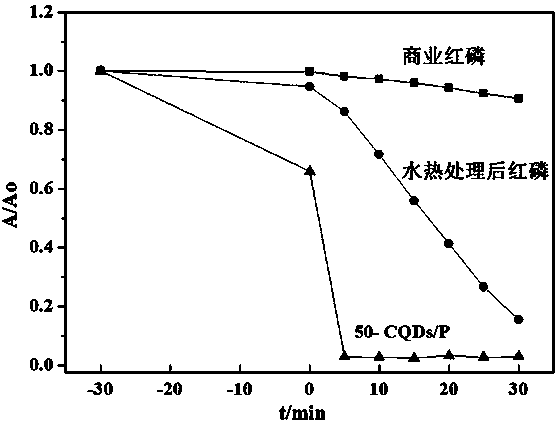

A composite material and photocatalytic technology, which is applied in the field of CQDs/P photocatalytic composite materials and their preparation, can solve the problems of few active sites for surface catalytic reactions, easy recombination of photogenerated currents, and large particle size, and achieves improved photocatalytic performance. Efficiency, suppression of recombination of electrons and holes, effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of the above-mentioned CQDs / P photocatalytic composite material comprises the following steps:

[0027] 1) Prepare carbon quantum dot solids by hydrothermal treatment with pollen as raw material, and then add water to make carbon quantum dot solution;

[0028] 2) Red phosphorus with mesoporous structure was prepared by crystal growth hydrothermal method, and red phosphorus with deionized water was mixed and hydrothermally treated to obtain red phosphorus with mesoporous structure;

[0029] 3) Dissolve the product obtained in step 2) in the carbon quantum dot solution, add polyvinylpyrrolidone (PVP), and stir the mixture at room temperature;

[0030] 4) The product in step 3) was washed with distilled water and dried in an oven to obtain the CQDs / P composite.

[0031] The specific steps for preparing the carbon quantum dot solution in step 1) are: mixing pollen with deionized water, transferring the mixture to a reactor for hydrothermal reaction a...

Embodiment 1

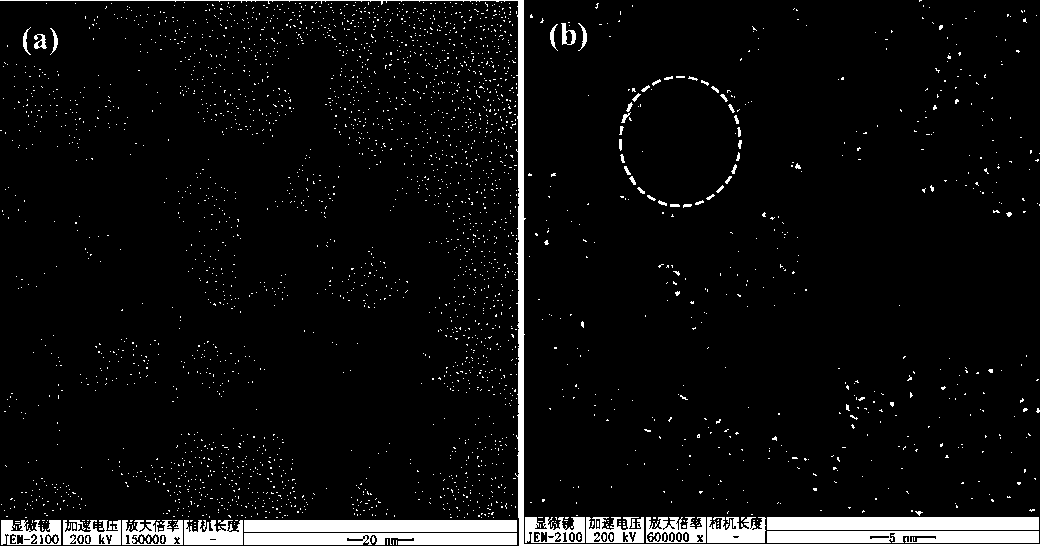

[0040] A CQDs / P photocatalytic composite material is composed of flake red phosphorus and carbon quantum dots. The red phosphorus has a mesoporous structure, the carbon quantum dots are distributed on the surface of the red phosphorus, and the red phosphorus exists in the form of a monoclinic phase.

[0041] The preparation method of CQDs / P photocatalytic composite material comprises the following steps:

[0042] S1. Using pollen as a raw material to prepare carbon quantum dot solids through hydrothermal treatment, and then add deionized water to form a carbon quantum dot solution;

[0043] Specifically: 1 g of pollen was mixed with 40 mL of water under ultrasonic conditions, and after stirring for 6 minutes, the mixture was transferred to a reaction kettle and sealed, heated at 150 °C for 12 hours, and naturally cooled to room temperature. The resulting suspension was dried in a freeze dryer to obtain a solid, which was prepared into a carbon dot solution with a concentration...

Embodiment 2

[0049] A CQDs / P photocatalytic composite material is composed of flake red phosphorus and carbon quantum dots. The red phosphorus has a mesoporous structure, the carbon quantum dots are distributed on the surface of the red phosphorus, and the red phosphorus exists in the form of a monoclinic phase.

[0050] The preparation method of CQDs / P photocatalytic composite material comprises the following steps:

[0051] S1. Using pollen as a raw material to prepare carbon quantum dot solids through hydrothermal treatment, and then add deionized water to form a carbon quantum dot solution;

[0052] Specifically: 2 g of pollen was mixed with 80 mL of water under ultrasonic conditions. After stirring for 7 minutes, the mixture was transferred to a reaction kettle, sealed, heated at 160 °C for 20 hours, and cooled to room temperature naturally. The resulting suspension was dried in a freeze dryer to obtain a solid, which was prepared into a carbon dot solution with a concentration of 8 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com