Anti-explosion soaking pot

A technology for hot pot and pot body, which is applied in indirect heat exchangers, lighting and heating equipment, special materials for cooking utensils, etc. The pot body has no heat dissipation effect and other problems, so as to achieve the effect of light weight, avoid burn injury, and strengthen low pressure resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

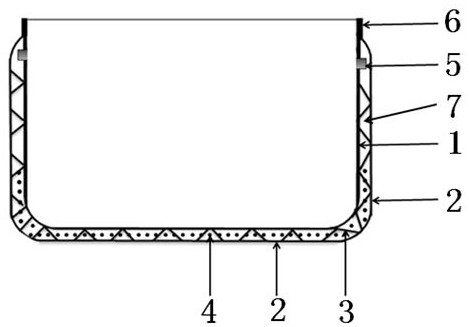

[0050] Such as figure 1 , figure 2 The shown explosion-proof soaking pot includes an inner pot body 1 , a working medium 4 , an outer pot body 2 , a liquid-absorbing core 3 and a low melting point alloy 8 .

[0051] There are air guide holes 5 on the inner pot body 1, and the diameter of the air guide holes 5 is 1 mm; the number of the air guide holes 5 is two.

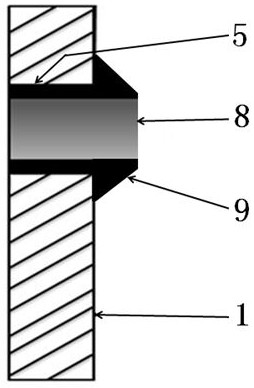

[0052] The air guide hole 5 is a hot-melt hole 9; the hot-melt hole 9 is a hot-melt hole 9 with a hot-melt cone made by a hot-melt drilling process.

[0053] The low melting point alloy 8 is fixed in the air guide hole 5 on the inner pot body 1, and the low melting point alloy 8 and the air guide hole 5 are fixed as one.

[0054] The low-melting point alloy 8 is surfacing welded on the air guide hole 5 on the outside of the inner pot body 1 through the heating equipment, the surface of the low melting point alloy 8 in the air guide hole 5 on the inner surface of the inner pot body 1 and the inner pot surface of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com