Anode for microbial fuel cell, preparation method of anode and microbial fuel cell

A fuel cell and microbial technology, applied in biochemical fuel cells, battery electrodes, circuits, etc., can solve the problems of poor conductivity of molybdenum disulfide and small specific surface area of the anode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

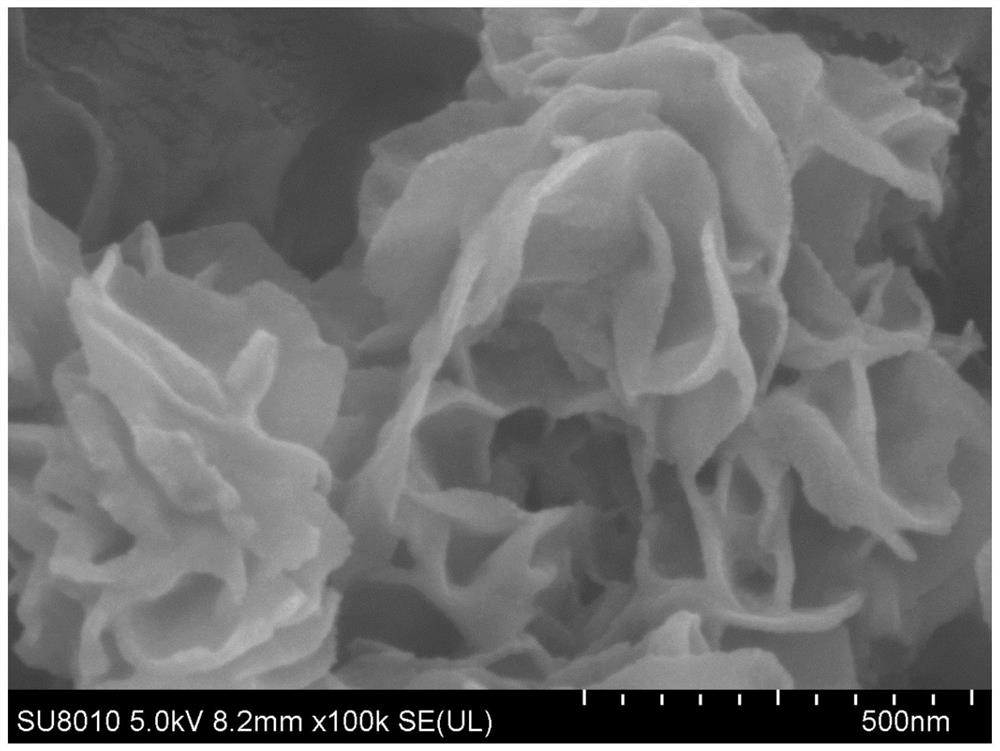

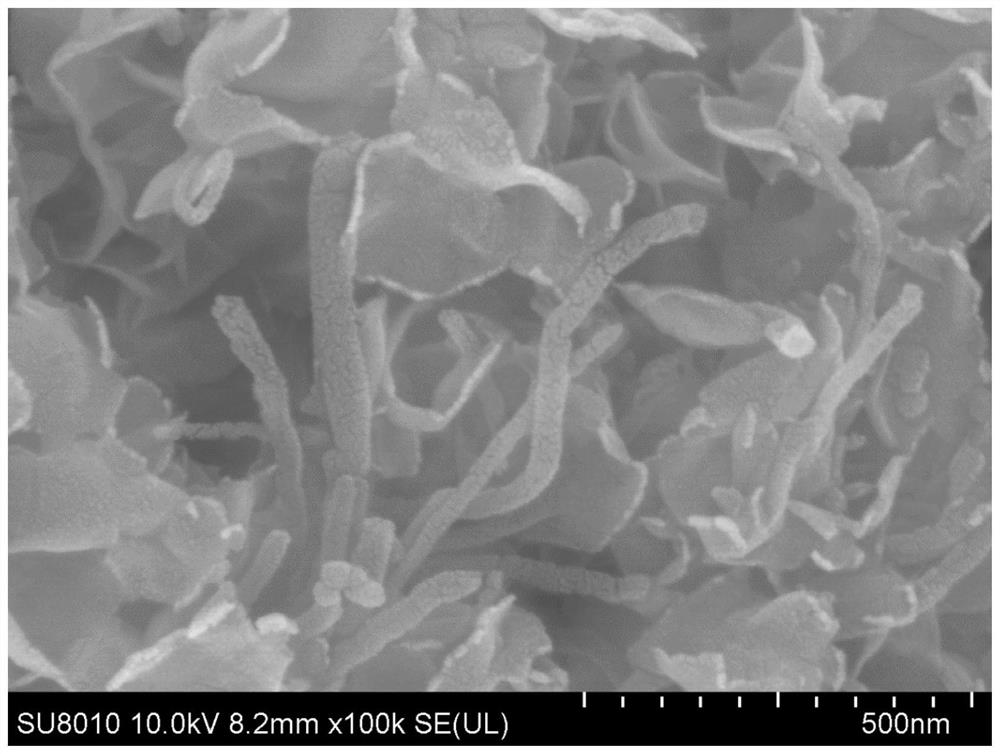

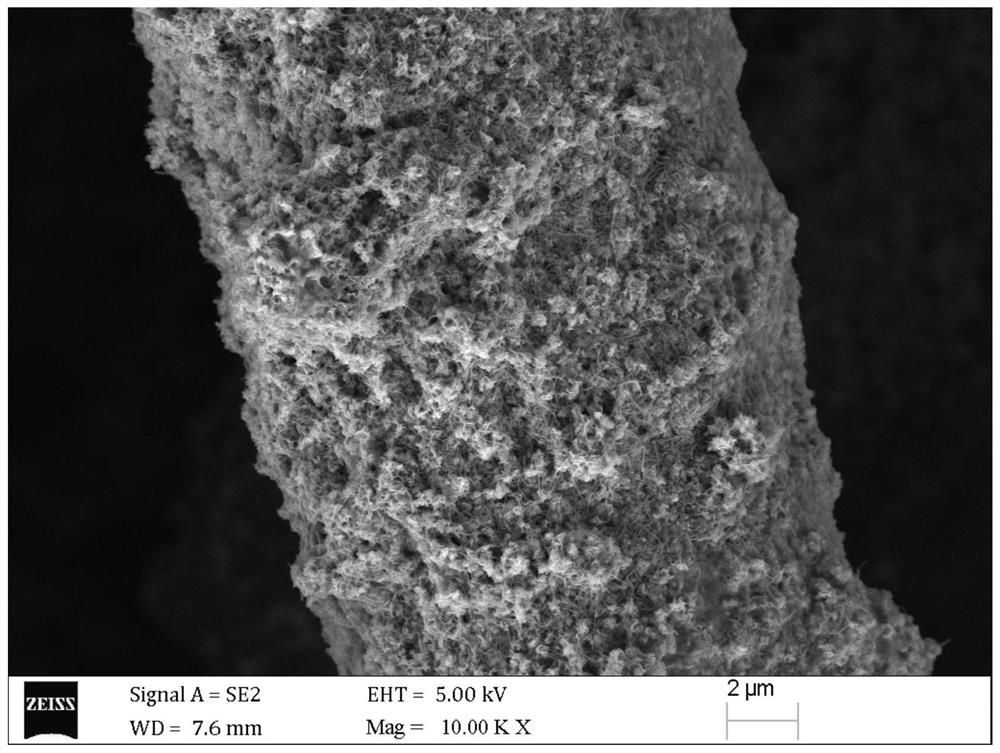

[0038]The anode for the microbial fuel cell of the present embodiment comprises carbon paper and a modification material attached to both sides of the carbon paper, the modification material includes molybdenum disulfide nanosheets and multi-walled carbon nanotubes dispersed between the molybdenum disulfide nanosheets; the modification material The adhesion on carbon paper is 1.5mg cm -2 The modified material is bonded on the carbon paper by nafion; the mass ratio of the modified material and nafion is 3:1; the modified material adopted is prepared by a method comprising the following steps:

[0039] Add 0.3506g of ammonium molybdate and 0.7635g of thiourea into 15mL of deionized water, ultrasonically dissolve for 10 minutes, then add 1g of multi-walled carbon nanotube aqueous dispersion (containing 0.1g of multi-walled carbon nanotubes) to continue ultrasonic dispersion for 30 minutes, and then Put the reaction system into a hydrothermal kettle for 8 hours at 200°C for hydrot...

Embodiment 2

[0042] The preparation method of the microbial fuel cell anode of the present embodiment is the preparation method of the microbial fuel cell anode of embodiment 1, comprising the following steps:

[0043] 1) Add 0.3506g of ammonium molybdate and 0.7635g of thiourea into 15mL of deionized water, ultrasonically dissolve for 10 minutes, then add 1g of multi-walled carbon nanotube aqueous dispersion (containing 0.1g of multi-walled carbon nanotubes) to continue ultrasonic dispersion for 30 Minutes, then put the reaction system into a hydrothermal kettle for hydrothermal reaction at 200°C for 8 hours, then collect the precipitated product, first wash the collected precipitated product three times with deionized water, then three times with absolute ethanol, and finally in the air Place it to dry to obtain the modification material;

[0044] 2) Mix the 5wt% nafion solution and dehydrated ethanol to obtain a mixed solution; the volume of dehydrated ethanol used for every 200mg of 5w...

Embodiment 3

[0047] The microbial fuel cell of the present embodiment is a dual-chamber microbial fuel cell, with the anode for the microbial fuel cell in Example 1 as the anode, the carbon paper as the cathode, and the Nafion 117 proton exchange membrane as the separation membrane; the anaerobic sludge For the mixed bacterial source, use the mixed solution as the anode nutrient solution; use 50mmol L -1 Potassium ferricyanide solution is the cathode solution. As a mixed solution of anode nutrient solution, it is 50mmolL per liter -1 Phosphate buffered saline solution (PBS buffer solution) was mixed with 1g sodium acetate, 12.5mL vitamin solution and 12.5mL mineral solution; 50mmolL -1 See Table 1-3 for the solutes and concentrations of the solutes in the phosphate buffer solution, the solutes and the concentrations of the solutes in the mineral solution, and the solutes and the concentrations of the solutes in the vitamin solution.

[0048] Table 1 50mmol L -1 Solute and concentration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com