Conveying system with automatic control dryer and control method of dryer

A conveying system and dryer technology, applied in dryers, drying safety systems, drying and other directions, can solve the problems of multiple human resources, inability to meet the needs of production lines, etc., to achieve convenient use, save labor costs and site costs , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

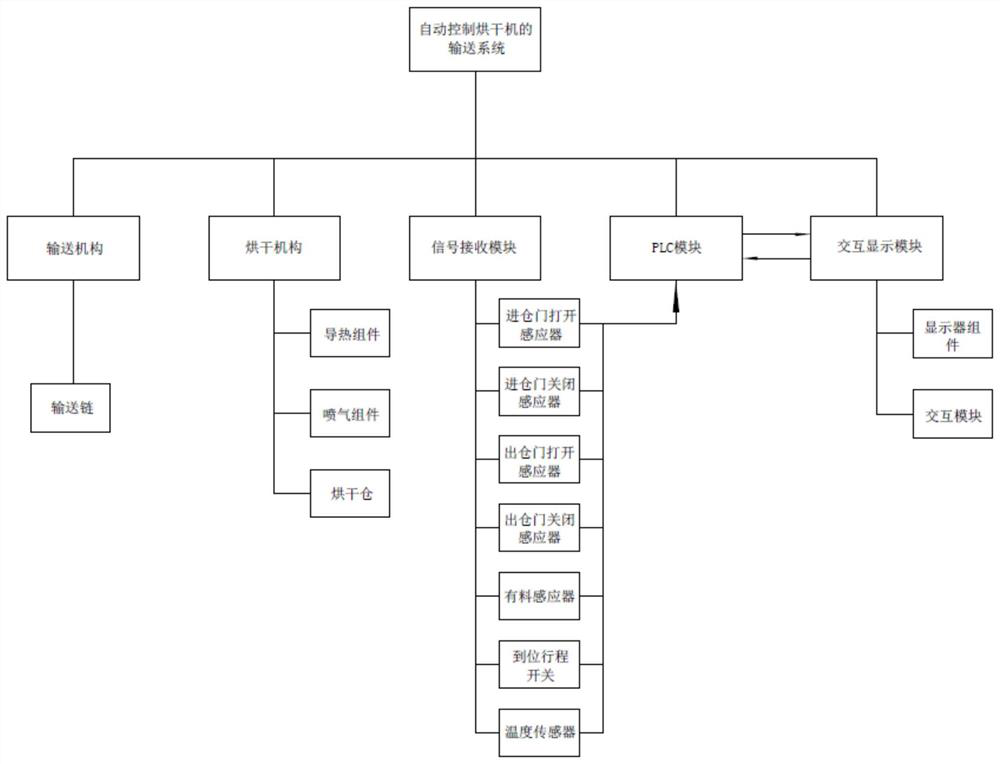

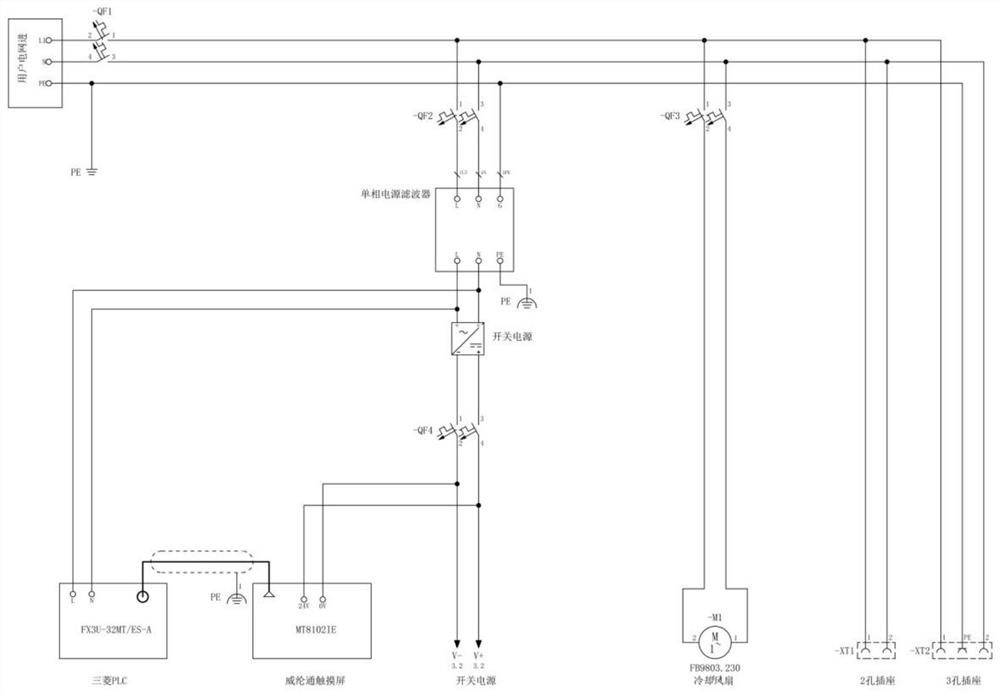

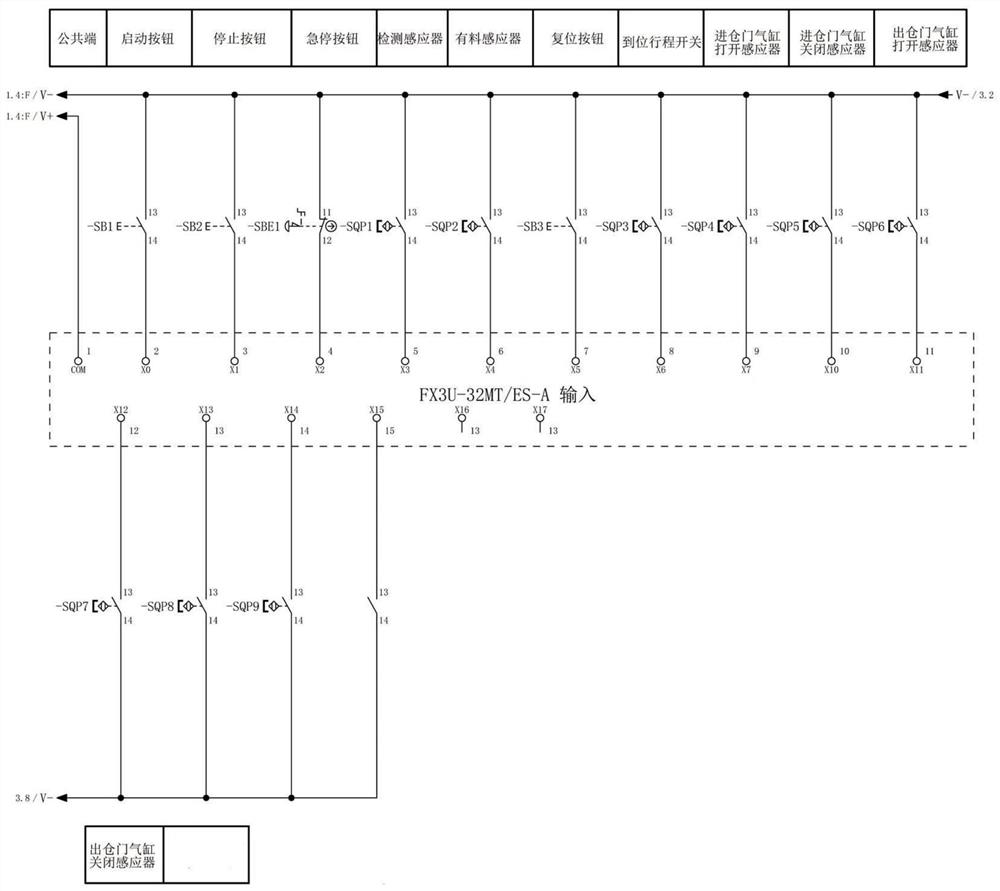

[0056] Taking the clothing industry as an example, such as figure 1 As shown, a conveying system with an automatic control dryer includes a drying mechanism; the conveying system with an automatic control dryer also includes an interactive display module, a signal detection module and a PLC that controls the automatic operation of the drying system module.

[0057] The drying mechanism is provided with a conveying chain and hangers for carrying clothes on the conveying chain; after the clothes are produced in the workshop, they can be transported to the drying mechanism by the hanging system in the production workshop through steam ironing To dry clothes, the conveyor chain is connected to the hanging system of the production workshop, or directly transported to the drying mechanism manually.

[0058] Drying mechanism: including a channel for clothes to be transported, and drying devices for drying clothes are symmetrically arranged on both sides of the channel, including hea...

Embodiment 2

[0086] In this embodiment, on the original basis, a detection unit for detecting the type of clothing is provided at the incoming material sensor; in this embodiment, there is no need to set the drying mode in advance, and when the detection unit detects the type of clothing, it will The current type of clothing is input into the PLC module, and the PLC module automatically adjusts the parameters of the drying mode in real time according to the corresponding type of clothing; and when the last set of clothing is detected, the first limit device is opened to send the clothing into the drying chamber. At the same time, the next group of clothes is detected. If the next group of clothes is of the same type as the previous group of clothes, then the first limit device is opened, and the next group of clothes is also sent into the drying chamber for drying at the same time. The clothes at the incoming material are detected at one time until the front and back clothes are of differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com