Preparation method of fibrilia antibacterial functional material

A functional material and technology of hemp fiber, applied in the field of antibacterial, can solve the problems of loss of antibacterial properties of hemp fiber, loss of antibacterial components, and inability to meet the antibacterial requirements of fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

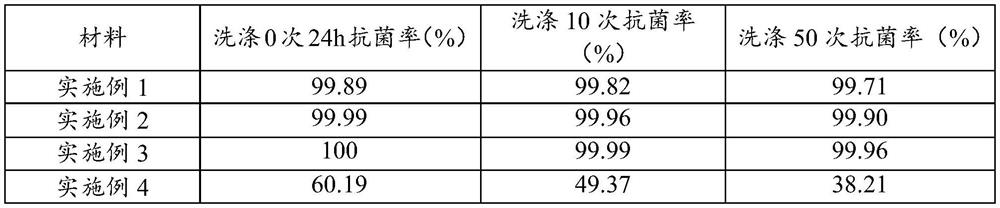

Examples

preparation example Construction

[0021] The invention provides a preparation method of hemp fiber antibacterial functional material, comprising:

[0022] Soak the hemp fiber in the aqueous solution of tannic acid to carry out the first reaction to obtain the pre-modified hemp fiber;

[0023] The premodified hemp fiber is subjected to a second reaction with metal ions and organic amines to obtain the antibacterial functional material of hemp fiber.

[0024] figure 1 It is the flow chart of preparing hemp fiber antibacterial functional material for the embodiment of the present invention.

[0025] In the present invention, the hemp fiber is an industrial hemp fiber that can be used for spinning after degumming, which can be purchased from the market, such as the products provided by Hunan Huasheng Co., Ltd. can be used.

[0026] In the present invention, the fiber body length of the hemp fiber is preferably ≥ 23 mm, the fiber count is preferably ≥ 1500 Nm, and the fiber breaking length is preferably ≥ 26 Km. ...

Embodiment 1

[0057] Prepare 20 mL of tannic acid (TA) aqueous solution with a mass concentration of 3%, add 0.2 g of industrial hemp fiber, and after the fiber is fully swollen, put it into a constant temperature water bath shaking box, shake at 50 ° C and 180 rpm for 6 hours;

[0058] Then the above reaction system was added dropwise under the condition of ultrasonic radiation containing FeCl 3 and triethylenetetramine (FeCl 3 and the molar concentration of triethylenetetramine in aqueous solution are 0.15mol / L) aqueous solution control TA, Fe 3+ The molar ratio with triethylenetetramine is 1:1:1, and the ultrasonic reaction is 30min under the condition of 40kHz;

[0059] After the reaction, cool the reaction system to room temperature, remove the fibers, wash with ethanol to remove unreacted reagents, then wash the fibers with distilled water, and dry them in an oven at 50°C to constant weight.

Embodiment 2

[0061] Prepare 20 mL of tannic acid aqueous solution with a mass concentration of 2%, add 0.2 g of industrial hemp fiber, and after the fiber is fully swollen, place it at room temperature for 24 hours;

[0062] Under the condition of ultrasonic radiation, dropwise add CuSO 4 and an aqueous solution of ethylenediamine (CuSO 4 and the molar concentrations of ethylenediamine in aqueous solution are 0.2mol / L and 0.4mol / L respectively), adjust TA, Cu 2+ The molar ratio of ethylenediamine and ethylenediamine is 1:2:4, and the ultrasonic reaction is performed at 40kHz for 10min;

[0063] After the reaction, the reaction system was cooled to room temperature, the fiber was taken out, washed with ethanol to remove unreacted reagents, then washed with distilled water, and dried in an oven at 50°C until constant weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com