Purification method of iron-chromium electrolyte and iron-chromium electrolyte obtained therefrom

A purification method and electrolyte technology, which is applied in the field of iron-chromium electrolyte and purified iron-chromium electrolyte, can solve problems such as electrolyte failure, hydrogen evolution, occurrence, etc., and achieve the goals of avoiding harmful side reactions, ensuring purity, and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

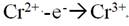

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0043]In the first embodiment of the present invention, a method for purifying an iron-chromium electrolyte for a flow battery is provided, which is characterized in that it includes the following steps:

[0044] Steps for providing an electrolytic cell having an anode, an anolyte, a cathode, and a membrane:

[0045] The step of passing the iron-chromium electrolyte to be purified through the surface of the cathode;

[0046] Wherein, the cathode includes metallic mercury and a porous conductive material, and when the iron-chromium electrolyte to be purified passes through the surface of the cathode, a reduction reaction occurs at least in part of the surface area of the cathode under the action of an external current.

[0047] anode and anolyte

[0048] In an embodiment of the invention, the anode comprises an anode material. The anode material may include a carbon-based material having a porous structure, and the pores can form a communication structure that accommodate...

no. 2 approach

[0079] The second embodiment of the present invention relates to a purification device for iron-chromium electrolyte, comprising the following structure:

[0080] Cell;

[0081] Cathode material import / export,

[0082] Wherein, the electrolytic cell includes an anode, a cathode and a diaphragm,

[0083] the cathode comprises metallic mercury and a porous conductive material, and

[0084] A space is formed between the cathode surface and the separator, which space is able to accommodate or allow the passage of the iron-chromium electrolyte to be purified.

[0085] The electrolytic cell is divided by a diaphragm into an anode part and a cathode part, and the anode part includes an anode material which is the same as that in the first embodiment of the present invention.

[0086] The cathode portion includes a cathode and a space formed between a separator and the cathode. The separator and cathode are the same as described in the first embodiment of the present invention. The...

Embodiment 1

[0112] In addition to introducing graphite felt, the electrode surface area of the cathode is increased to about 1100 cm 2 1. Except that the flow velocity of the iron-chromium electrolyte becomes 1L / min, the iron-chromium negative electrode electrolyte after purification in Comparative Example 1 is further purified using the same purification device and method as in Comparative Example 1.

[0113] After further purification, the impurity contents of various metal ions in the iron-chromium electrolyte are as follows: Cu content is 10ppb, Ni content is 15ppb, Pt content is 3ppb, Au content is 0, Ag content is 8ppb, and the total content is 36ppb.

[0114] After the iron-chromium electrolyte is purified by purification equipment, it is loaded with a conventional reaction area of 25cm 2 , the positive and negative liquid storage bottles are respectively 150ml liquid flow cells for charge and discharge cycle.

[0115] The battery is continuously charged and discharged, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com