Purification additive and purification method for anti-ammonia steam turbine oil and emulsified ammonia-containing lubricating oil

A technology of steam turbine oil and lubricating oil, which is applied in the field of lubricating oil, which can solve the problems of affecting product quality, large amount of lubricating oil used, and high cost, and achieve the effects of improving demulsification performance, realizing oil-water separation, and extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

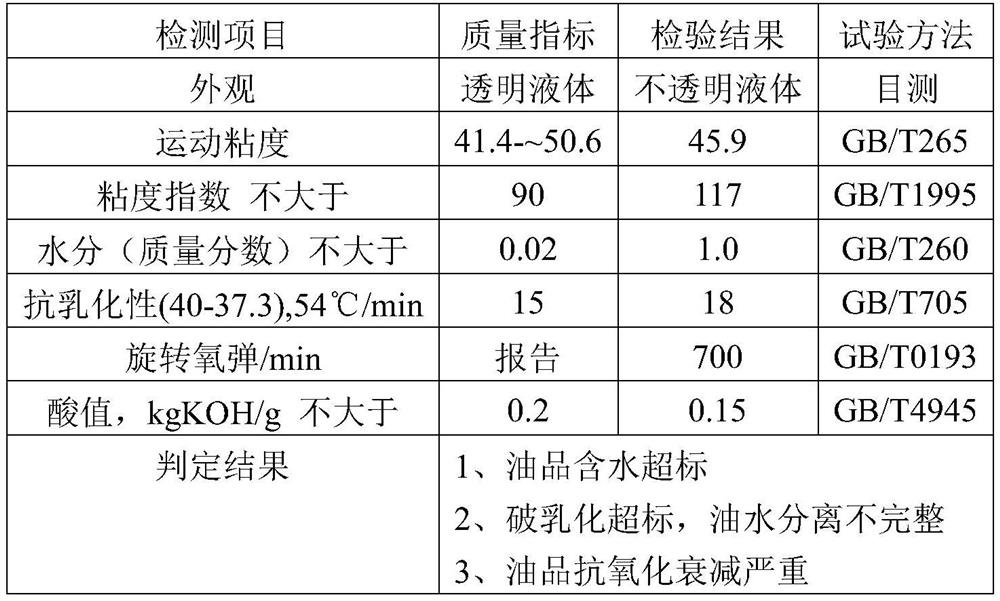

[0035] The purification of the ammoniacal lubricating oil of embodiment 1 emulsification

Embodiment 1-1

[0037] A method for purifying emulsified ammonia-containing lubricating oil, the steps of which are:

[0038] (1) Stir 100 parts by weight of sample A to raise the temperature to 65±5°C;

[0039] (2) Add anti-foaming agent and demulsifier in turn, stir at constant temperature, then add antioxidant, metal passivator, anti-wear agent, stir evenly to achieve demulsification;

[0040] (3) Filtration and oil-water separation, that is, the purification of the emulsified ammonia-containing lubricating oil, and the detection of the lubricating oil after demulsification. The dosage and test results of each substance are shown in Table 3.

[0041] 0.5 part of antioxidant, 0.5 part of metal deactivator, 0.005 part of silicone oil antifoaming agent, 10 ppm of T1001 demulsifier, 3 parts of antiwear agent. The above-mentioned antioxidant is alkylated diphenylamine (liquid), the metal deactivator is 2,5-dimercapto-1,3,4-thiodiol derivative, and the anti-wear agent is nano-alumina and nano-...

Embodiment 1-2

[0043] A method for purifying emulsified ammonia-containing lubricating oil, the steps of which are:

[0044] (1) Stir 100 parts by weight of sample A to raise the temperature to 65±5°C;

[0045] (2) Add anti-foaming agent and demulsifier in turn, stir at constant temperature and then add antioxidant, metal deactivator, anti-wear agent, stir evenly to realize demulsification; the consumption of each material is shown in Table 3;

[0046] (3) Filtrate, carry out oil-water separation, realize the purification of the emulsified ammonia-containing lubricating oil, detect the lubricating oil after demulsification, and the detection results are shown in Table 4.

[0047] Among them, 0.3 parts of antioxidant, 0.5 parts of metal deactivator, 0.005 parts of silicone oil antifoaming agent, 20 ppm of T1001 demulsifier, and 3.5 parts of antiwear agent.

[0048] The above-mentioned antioxidant is alkylated diphenylamine (liquid), the metal deactivator is 2,5-dimercapto-1,3,4-thiodiol deri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com