a p 204 Preparation method and application of doped polythiophene light rare earth solid phase extractant

A solid-phase extraction agent, polythiophene technology, applied in the direction of improving process efficiency, etc., can solve the problems of easy to produce emulsification, difficult to handle organic waste liquid, easy to produce third phase, and achieve difficult emulsification, low price, and reduced The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

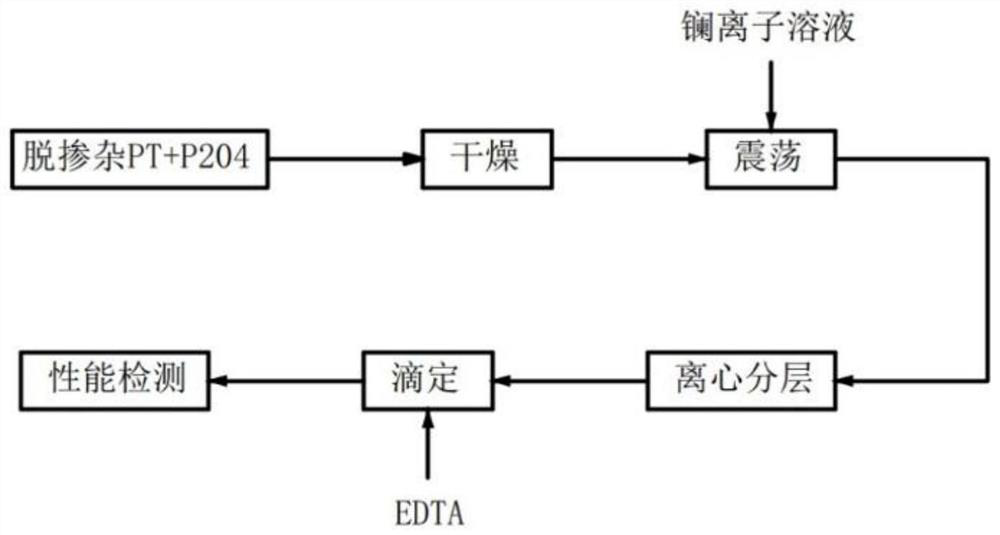

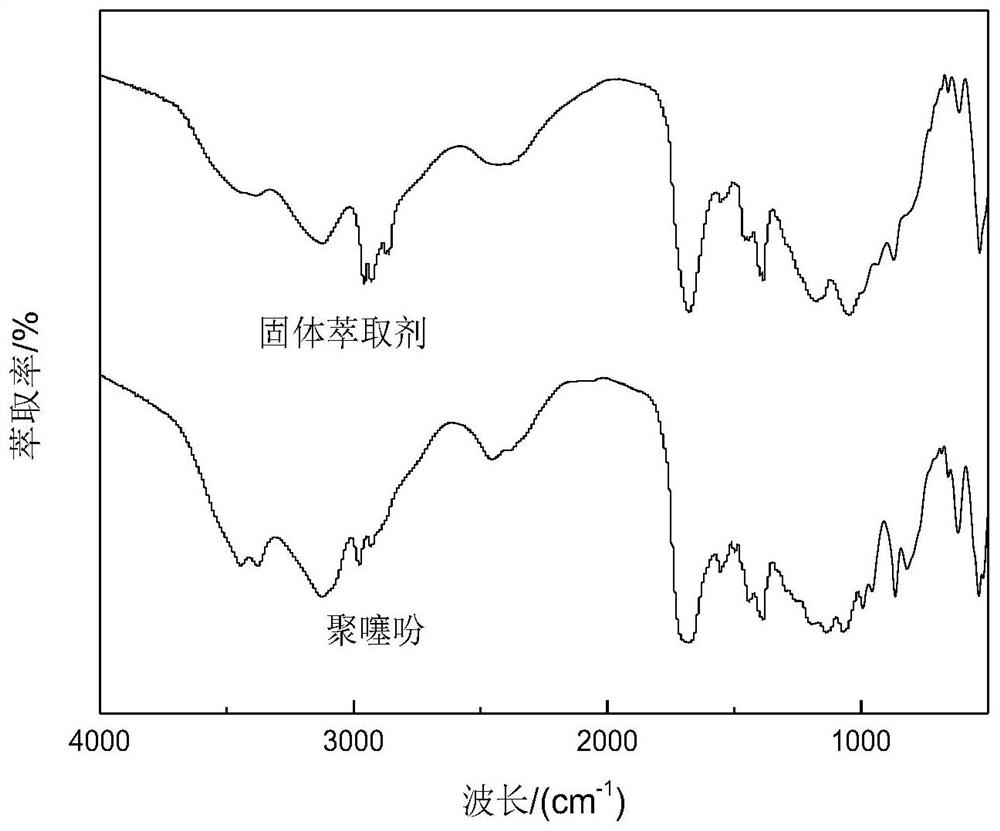

[0034] Embodiment 1: as figure 1 As shown, in this embodiment a P 204 The preparation and method thereof of doped polythiophene light rare earth solid-phase extraction agent are carried out according to the following steps:

[0035] (1) to contain La 3+ The rare earth chloride solution is the raw material solution, La 3+ The concentration of the rare earth solution is 0.01mol / L, and the pH of the rare earth solution is adjusted to 3.00 with inorganic acid;

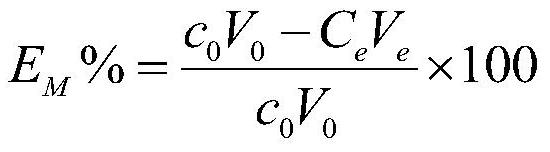

[0036] (2) The rare earth raw material liquid is mixed with a solid extractant for extraction, P 204 The ratio with polythiophene is 0.30ml / g, the dosage of solid phase extraction is 0.2g, the rotation speed is 200r / min, the extraction time is 30min, and the extraction temperature is 25°C. After the extraction is completed, the mixed solution is filtered through a suction filtration device to separate the raffinate and the solid phase extractant. The concentration of the rare earth in the aqueous phase was measured, a...

Embodiment 2

[0038] (1) to contain La 3+ The rare earth chloride solution is the raw material solution, La 3+ The concentration of the rare earth solution is 0.005mol / L, and the pH of the rare earth solution is adjusted to 5.00 with inorganic acid;

[0039] (2) The rare earth raw material liquid is mixed with a solid extractant for extraction, P 204 The ratio with polythiophene is 0.70ml / g, the amount of solid extractant is 0.2g, the rotation speed is 200r / min, the extraction time is 30min, and the extraction temperature is 25°C. After the extraction is completed, the mixed solution is filtered through a suction filtration device to separate the raffinate and the solid phase extractant. The rare earth concentration in the aqueous phase was measured, and the extraction rate was calculated to be 61.9%.

Embodiment 3

[0041] (1) to contain La 3+ The rare earth chloride solution is the raw material solution, La 3+ The concentration of the rare earth solution is 0.01mol / L, and the pH of the rare earth solution is adjusted to 3.00 with inorganic acid;

[0042] (2) The rare earth raw material liquid is mixed with a solid extractant for extraction, P 204 The ratio with polythiophene is 0.30ml / g, the dosage of solid phase extraction is 0.5g, the rotation speed is 400r / min, the extraction time is 30min, and the extraction temperature is 25°C. After the extraction is completed, the mixed solution is filtered through a suction filtration device to separate the raffinate and the solid phase extractant. The rare earth concentration in the aqueous phase was measured, and the extraction rate was calculated to be 71.42%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com