Hydrodynamic cavitation assisted liquid-liquid extraction device and extraction method

A technology of hydrodynamic cavitation and extraction device, applied in chemical instruments and methods, liquid solution solvent extraction, mixing methods, etc., can solve the problems of low extraction efficiency, fast layering speed, unfriendly environment, etc. The effect of enhancing the degree of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

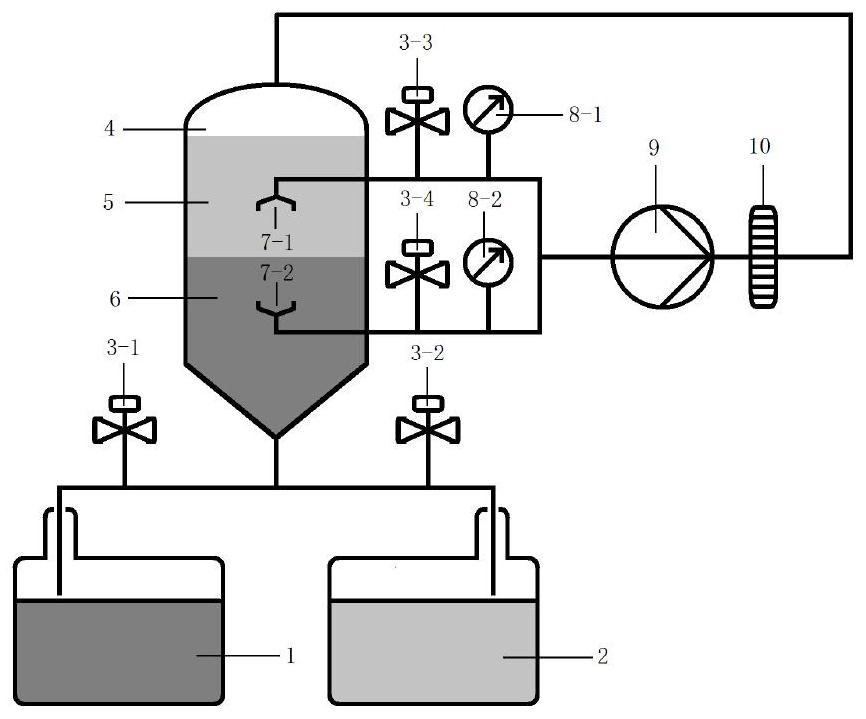

[0025] Example 1 Orifice plate type hydraulic cavitation-assisted liquid-liquid extraction device

[0026] like figure 1 As shown, the orifice plate type hydraulic cavitation assisted liquid-liquid extraction device includes: horizontal storage tank I (1), horizontal storage tank II (2), extraction tank (4), pressure pump (9) and hydraulic Cavitation device.

[0027] In this embodiment, the orifice plate (10) is selected for the hydraulic cavitation device. The orifice plate (10) is a cylindrical plate with 1-100 through holes. The through holes are cylindrical holes or square holes. Preferably, in this embodiment, the orifice plate (10) is a cylindrical plate with a thickness of 4 mm, and the orifice plate is provided with three through holes, and the through holes are cylindrical holes with a diameter of 5 mm.

[0028] A valve I (3-1) is connected to the inlet pipe of the horizontal storage tank I (1).

[0029] A valve II (3-2) is connected to the inlet pipe of the hori...

Embodiment 2

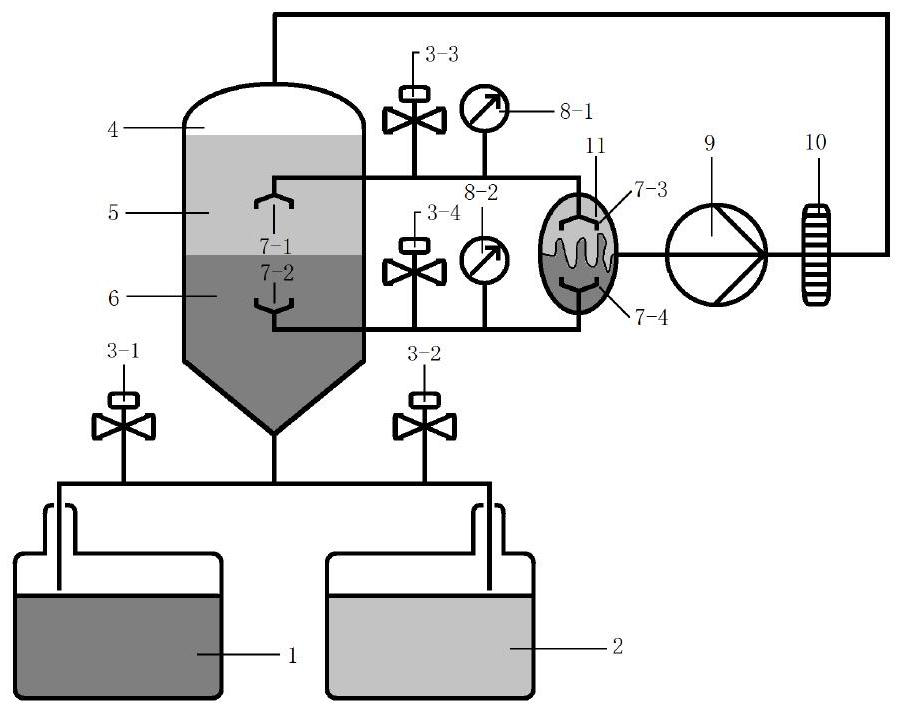

[0036] Example 2 Liquid-liquid extraction device assisted by collider and orifice plate type hydraulic cavitation

[0037] like figure 2 As shown in the figure, the collider and orifice type hydraulic cavitation-assisted liquid-liquid extraction device includes: horizontal storage tank I (1), horizontal storage tank II (2), extraction tank (4), pressure pump ( 9), a collider (11) and a hydraulic cavitation device.

[0038] In this embodiment, the orifice plate (10) is selected for the hydraulic cavitation device. The orifice plate (10) is a cylindrical plate with 1-100 through holes. The through holes are cylindrical holes or square holes. Preferably, in this embodiment, the orifice plate (10) is a cylindrical plate with a thickness of 4 mm, and the orifice plate is provided with three through holes, and the through holes are cylindrical holes with a diameter of 5 mm.

[0039] A valve I (3-1) is connected to the inlet pipe of the horizontal storage tank I (1).

[0040] A...

Embodiment 3

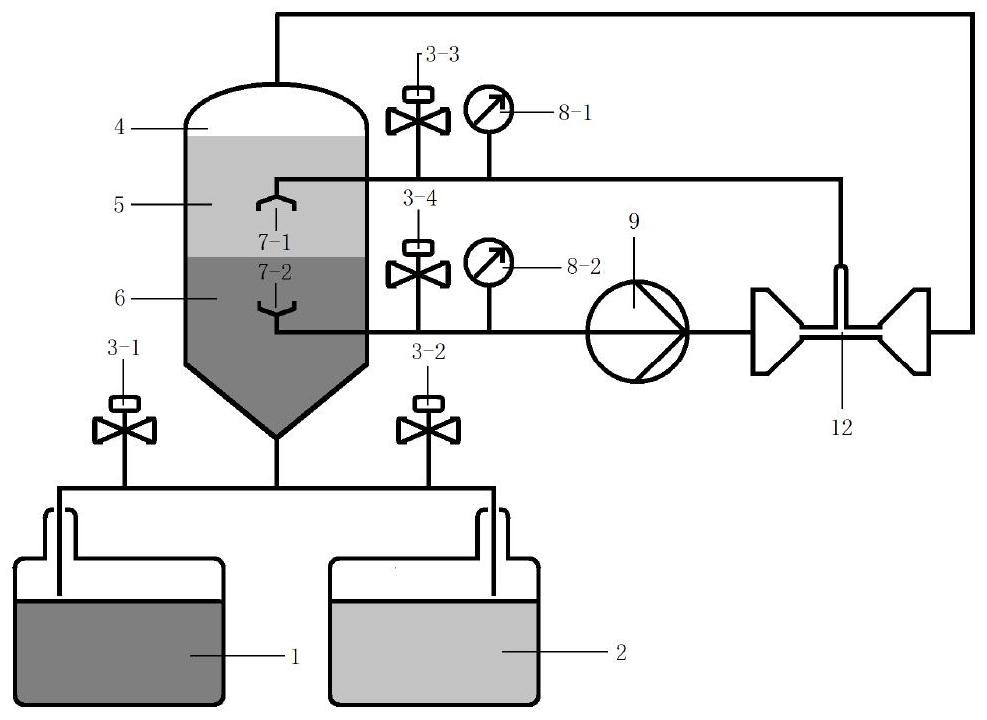

[0047] Example 3 Venturi-type hydraulic cavitation-assisted liquid-liquid extraction device

[0048] like image 3 As shown in the figure, the Venturi-type hydraulic cavitation-assisted liquid-liquid extraction device includes: horizontal storage tank I (1), horizontal storage tank II (2), extraction tank (4), pressure pump (9) and Hydraulic cavitation device.

[0049] In this embodiment, the Venturi tube (12) is selected as the hydraulic cavitation device. The venturi (12) consists of a constricted section, a throat area and a dilated section.

[0050] A valve I (3-1) is connected to the inlet pipe of the horizontal storage tank I (1).

[0051] A valve II (3-2) is connected to the inlet pipe of the horizontal storage tank II (2).

[0052] The horizontal storage tank I (1) and the horizontal storage tank II (2) are connected with the outlet of the extraction tank (4) through pipes.

[0053] The extraction tank (4) is provided with a suction pipe head I (7-1) and a suction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com