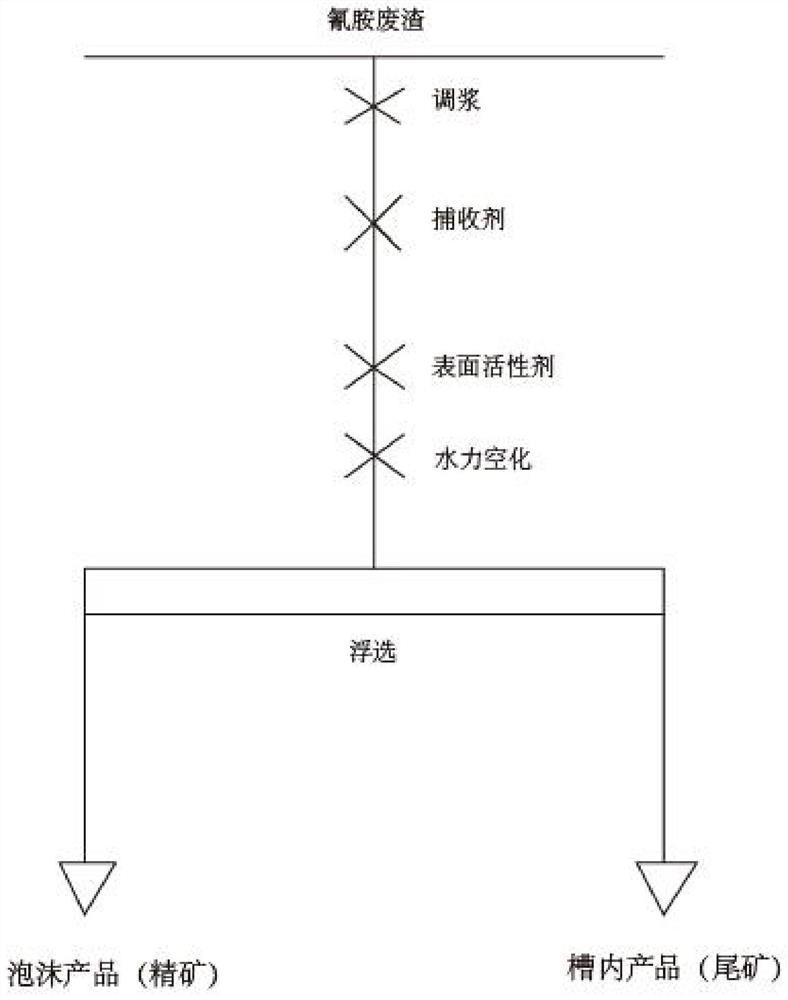

A kind of cyanamide waste residue flotation separation method enhanced by hydraulic cavitation

A technology of hydraulic cavitation and separation method, which is applied in flotation, solid separation, etc., can solve the problems of low efficiency and achieve the effect of improving the effect and effective flotation separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A cyanamide waste residue flotation separation method enhanced by hydraulic cavitation, the specific steps are: 1) weigh a certain amount of cyanamide waste residue and put it into a stirring tank and add water, wherein the mass ratio of water to cyanamide waste residue is 2:1 , stirring and mixing for 1min; 2) After mixing, add collector diesel oil 30L / t, stir for 1min, add surfactant isooctanol 1L / t, stir for 1min; 3) Pump into the aperture at a flow rate of 500L / h The orifice plate is 0.1mm and the number of openings is 5. The two ends of the orifice plate are connected to the pipeline through flanges, maintaining the cavitation pressure of 0.5Mpa, the system temperature of 20°C, and the initial cavitation; 4) Slurry after cavitation Continue to feed into the cavitation element, repeat the cavitation operation 4 times, and obtain the slurry after circulating cavitation; 5) collect the slurry after circulating cavitation, stir evenly, and carry out 1-stage flotation. ...

Embodiment 2

[0030] A cyanamide waste residue flotation separation method enhanced by hydraulic cavitation, the concrete steps are: 1) weigh a certain amount of cyanamide waste residue and put it into a stirring tank and add water, wherein the dewatering and cyanamide waste residue mass ratio is 2: 1. Stir and mix for 3 minutes; 2) After mixing, add 50L / t of collector diesel oil, stir for 3 minutes, add 2.5L / t of surfactant isooctyl alcohol, and stir for 3 minutes; 3) Use a pump to pump at a flow rate of 800L / h An orifice plate with an entrance diameter of 5mm and a number of openings of 10. The two ends of the orifice plate are connected to the pipeline through flanges, maintaining a cavitation pressure of 3Mpa, a system temperature of 30°C, and initial cavitation; 4) Slurry after cavitation Continue to feed into the cavitation element, repeat the cavitation operation 9 times, and obtain the slurry after circulating cavitation; 5) collect the slurry after circulating cavitation, stir evenl...

Embodiment 3

[0032] like figure 1 As shown, a kind of cyanamide waste residue flotation separation method enhanced by hydraulic cavitation, the concrete steps are: 1) weigh a certain amount of cyanamide waste residue and put it into a stirring tank and add water, wherein, the mass ratio of water and cyanamide waste residue is 2:1, stirring and mixing for 8min; 2) After mixing, add collector diesel oil 70L / t, stir for 8min, add surfactant isooctanol 4L / t, stir for 8min; 4) Use a pump with a flow rate of 1500L / h The orifice plate with a diameter of 10 mm and a number of openings of 20 is fed into the orifice plate. The two ends of the orifice plate are connected to the pipeline through flanges, the cavitation pressure is maintained at 6Mpa, the system temperature is 40°C, and the initial cavitation is performed; 4) Slurry after cavitation The material continues to pass into the cavitation element, and the cavitation operation is repeated 9 times to obtain the slurry after circulating cavitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com