Spodumene ore flotation method

A technology of spodumene ore and spodumene, applied in flotation, solid separation, etc., can solve the problems of difficult wastewater treatment and recycling, poor sedimentation dehydration performance, etc., to increase the difference in hydrophobicity and floatability, reduce Surface repulsion, the effect of reducing the number of negative charges on the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0047] According to a kind of preferred embodiment of the present invention, spodumene ore flotation method comprises the following steps:

[0048] (1) After the spodumene raw ore is crushed, the ore particles with a particle size less than or equal to 3 mm are screened out as mineral materials;

[0049] (2) Grinding the mineral material after mixing it with water, grinding the mineral material to a fineness of -0.074mm, accounting for 70-80wt%, and then mixing with water so that the mass fraction of the mineral material is 20-30% to obtain a pulp I;

[0050] (3) After the ore slurry I was settled for 1-3min, after removing the upper suspension, it was mixed with water so that the mass fraction of the mineral material in the slurry was 20-30%, and then mixed with a regulator to adjust Slurry II is obtained as slurry, and the slurry is mixed with a collector for stirring and pulping III to obtain pulp II. The regulator contains lignosulfonate, and the collector contains oleic ...

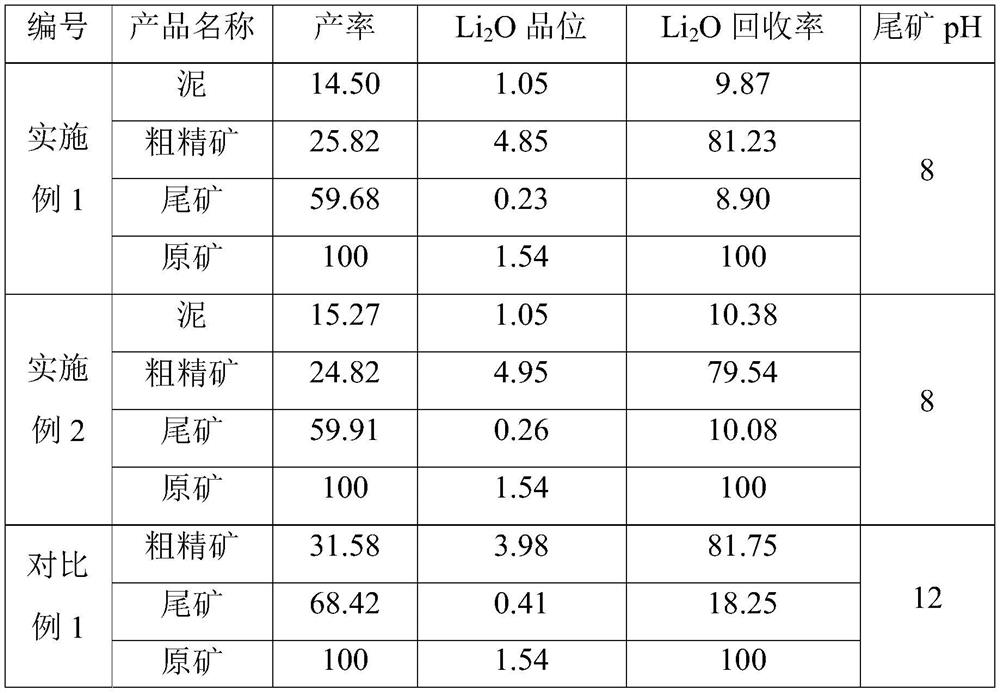

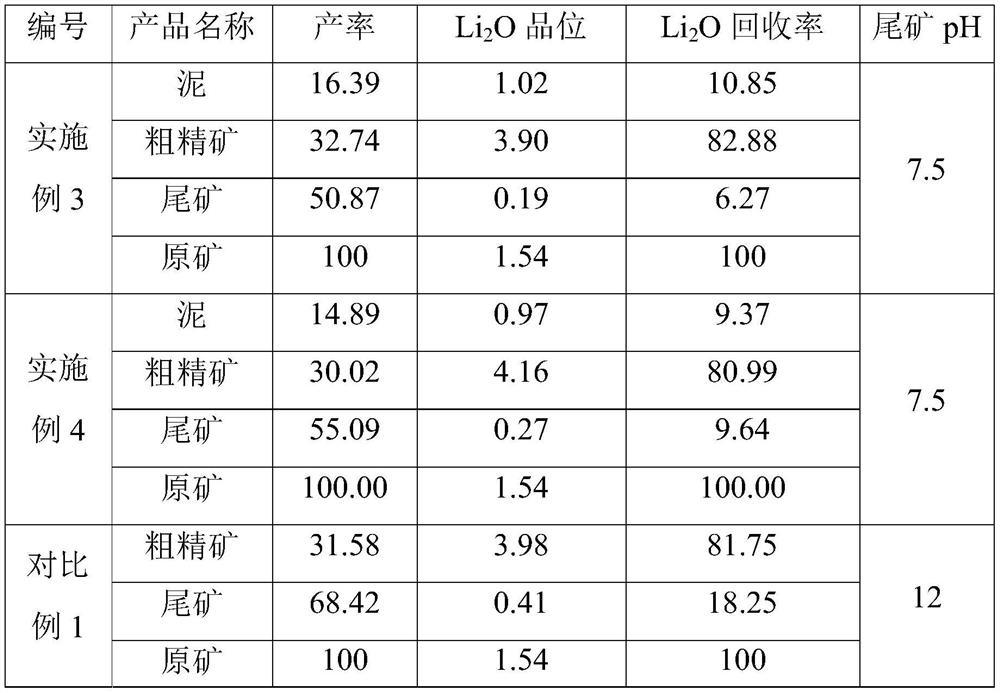

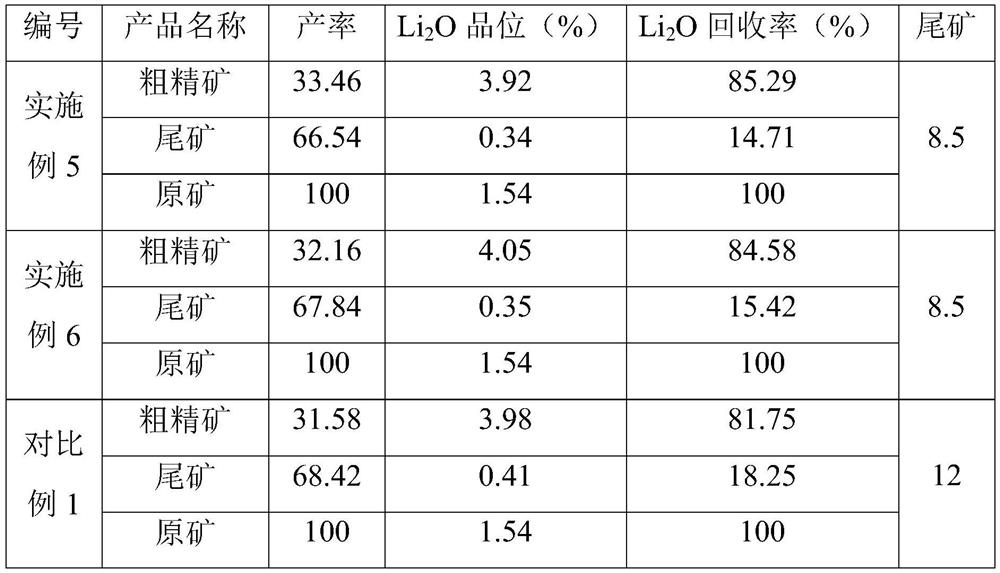

Embodiment 1

[0060] (1) Put the spodumene raw ore into the crusher for crushing, and screen the ore particles with a particle size less than or equal to 3mm as the mineral material;

[0061] (2) get 350g of mineral material that step (1) obtains and put into ball mill, add 350mL water, be ground to mineral material fineness-0.074mm by ball mill and account for 75wt%, then mix with water so that the massfraction of described mineral material is 25%, obtain pulp I;

[0062] (3) the ore slurry 1 that step (2) is obtained is stirred 2min in the flotation cell, then stops stirring, and after settling 2min, removes the supernatant suspension through extracting, and the ore slime that removes accounts for about 15wt% of ore material, and then with Mix with water to obtain a slurry with a mass fraction of mineral material of 25%, add 0.22g sodium lignosulfonate, adjust the linear speed of the stirring impeller of the flotation machine to 6.5m / s, stir for 8min to obtain a slurry, and then add 0.3g...

Embodiment 2

[0065] (1) Put the spodumene raw ore into the crusher for crushing, and screen the ore particles with a particle size less than or equal to 3mm as the mineral material;

[0066] (2) get 350g of mineral material that step (1) obtains and put into ball mill, add 350mL water, be ground to mineral material fineness-0.074mm by ball mill and account for 75wt%, then mix with water so that the massfraction of described mineral material is 25%, obtain pulp I;

[0067] (3) the ore slurry 1 that step (2) is obtained is stirred 2min in the flotation cell, then stops stirring, and after settling 2min, removes the supernatant suspension through extracting, and the ore slime that removes accounts for about 15wt% of ore material, and then with Mix with water to obtain a slurry with a mass fraction of mineral material of 25%, add 0.22g sodium lignosulfonate, adjust the linear speed of the stirring impeller of the flotation machine to 6.5m / s, stir for 8min to obtain a slurry, and then add 0.3g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com