Copper-molybdenum mixed concentrate sulfuric acid pretreatment separation flotation method

A copper-molybdenum mixed concentrate and pretreatment technology, applied in flotation, solid separation, etc., can solve the problems of rapid chemical consumption, environmental pollution, high price, etc., to reduce the amount of inhibitors, improve the separation effect, and reduce the amount of chemical agents little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

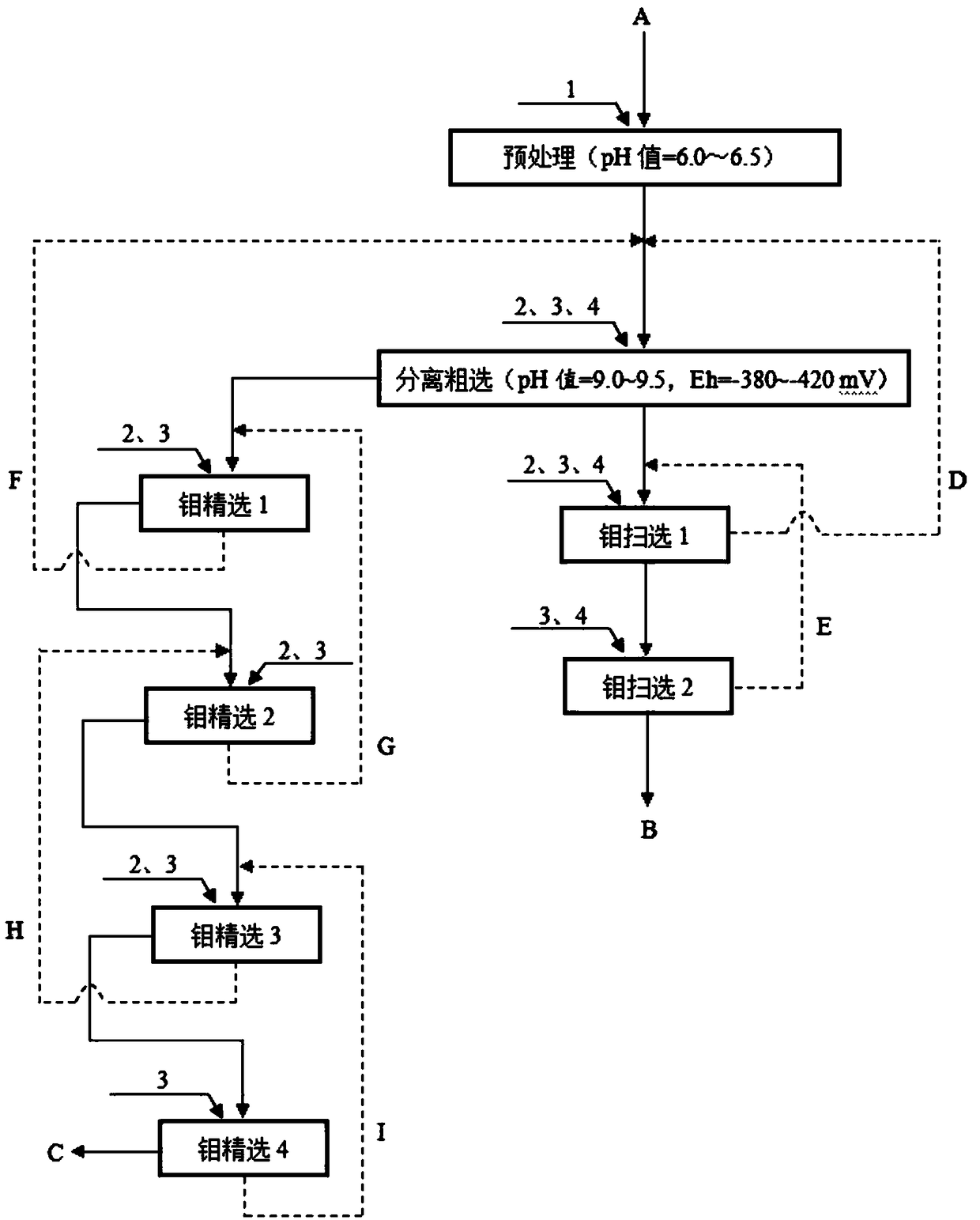

Method used

Image

Examples

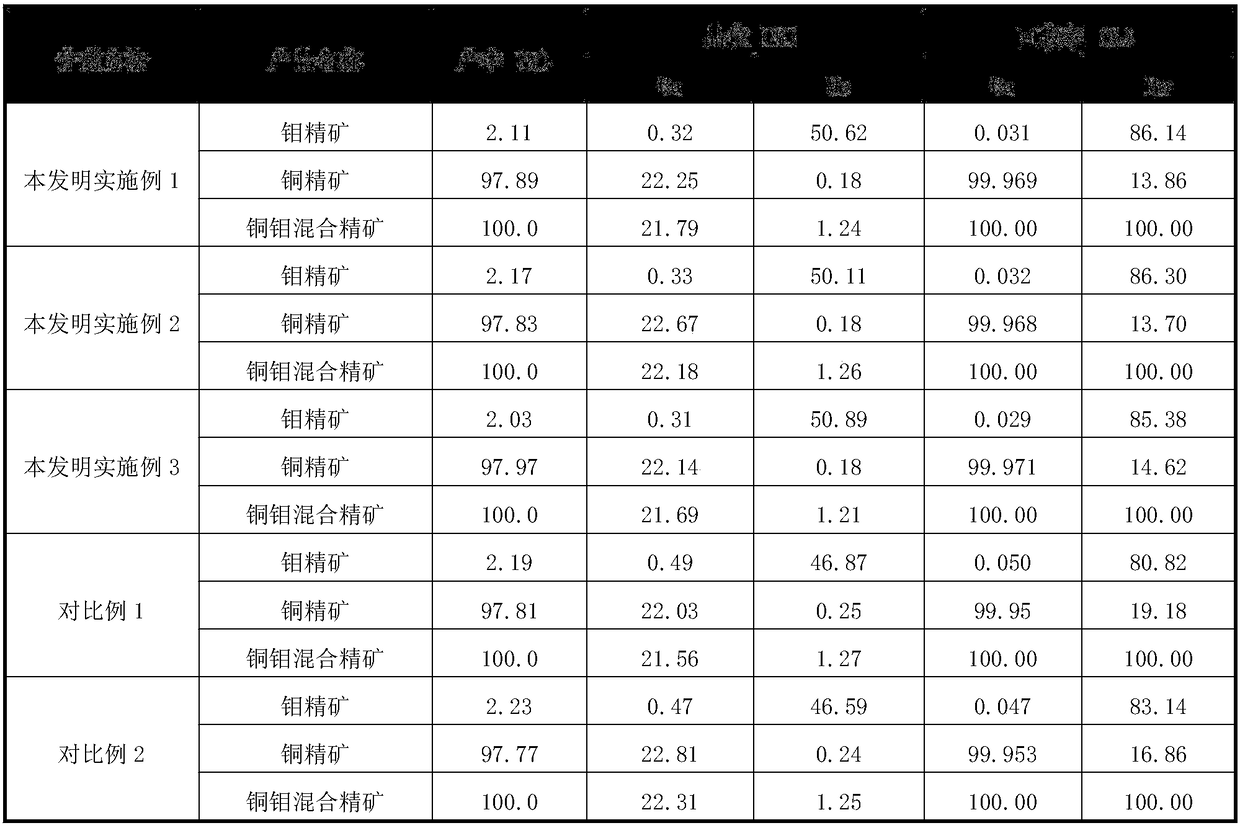

example 1

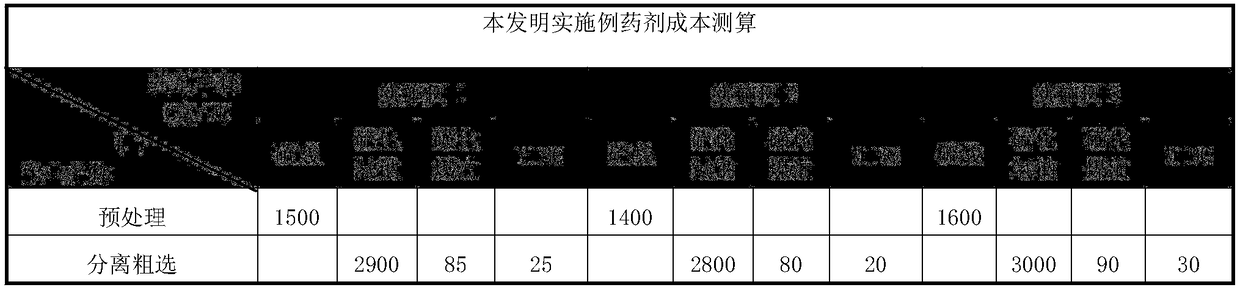

[0027] The copper-molybdenum mixed concentrate obtained by flotation is introduced into the stirring tank for stirring and slurrying, and the amount of sulfuric acid is added at 1500 g / ton ore, and stirred for 20 minutes to keep the pH value of the slurry at 6.0-6.5; the sulfuric acid pretreated The copper-molybdenum mixed concentrate is introduced into the flotation machine, and the amount of sodium hydrosulfide is added at 2900 g / ton ore, and stirred for 3 minutes to increase the pH value of the pulp to 9.0~9.5, Eh is -360~380mV, and the amount of sulfonated kerosene is added at 85 g / t Ton of ore, MIBC dosage 25 g / ton of ore, stirring for 1 minute each, and separation and roughing; add sodium hydrosulfide dosage of 450 g / ton of ore to the tailings of separation and roughing, stir for 3 minutes, add sulfonated kerosene dosage of 25 g / ton of ore, MIBC dosage 7.5 g / ton ore, stirring for 1 minute each, molybdenum sweeping 1; add sulfonated kerosene dosage 12.5 g / ton to the tailin...

example 2

[0029] The specific implementation method and process are the same as in Example 1 except that the amount of medicament added by each operation is changed from Example 1.

Embodiment 3

[0031] The specific implementation and process are the same as in Examples 1 and 2, except that the amount of medicament added by each operation is changed from that of Example 1 and Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com