Novel preparation method of bromopropylate

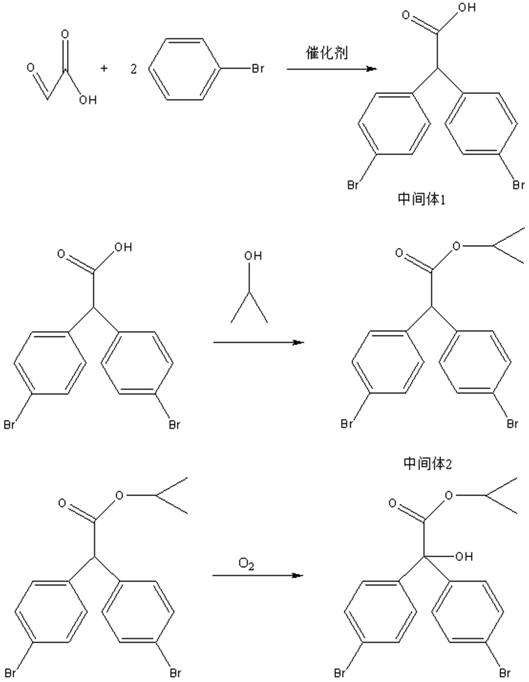

A technology of bromodifen and bromobenzene, which is applied in the new preparation field of bromite, can solve the problems of serious self-polymerization of glyoxylic acid, many wastes, low yield, etc., so as to reduce the generation of wastes and increase the reaction yield. efficiency, improving the reaction selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1, the preparation of intermediate 1:

[0028] Put 180.00g of 40% glyoxylic acid into the reaction kettle, dehydrate under the condition of 40-80℃ / -0.095MPa for 1-2 hours, add 296.00g of toluene to reflux with water until it is basically anhydrous (control the moisture below 0.5%), Cool down to 20-50°C and put in 5.55g of acidic catalyst, raise the temperature, add 63.64g of 99% isopropanol dropwise in the reflux state, bring water back to the reflux, control glyoxylic acid below 0.5%, cool to 20-50°C, Add 185.00 g of washing water, separate the phases, and desolventize the organic phase to obtain 115.01 g of 98% isopropyl glyoxylate, namely intermediate 1.

[0029] Step 2, the preparation of intermediate 2:

[0030] Add 5.55g of Lewis acid and 407.00g of 99% bromobenzene to intermediate 1, raise the temperature to 20-50°C, add 185.00g of 98% water-absorbing agent dropwise, stir for 2-5 hours, the reaction is complete, and cool down for 20 Below ℃, add 296.00g of...

Embodiment 2

[0036] Step 1, the preparation of intermediate 1:

[0037] Put 185.00g of 40% glyoxylic acid into the reaction kettle, dehydrate under the condition of 40-80℃ / -0.095MPa for 1-2 hours, add 370.00g of toluene to reflux with water until it is basically anhydrous (control moisture below 0.5%), Cool down to 20-50°C and put in 9.25g of acidic catalyst, raise the temperature, add 66.67g of 99% isopropanol dropwise under reflux, bring water back to the reflux, control glyoxylic acid below 0.5%, cool to 20-50°C, Add 203.50 g of washing water, separate the phases, and desolventize the organic phase to obtain 115.00 g of 98% isopropyl glyoxylate, namely intermediate 1.

[0038] Step 2, the preparation of intermediate 2:

[0039] Add 9.25g Lewis acid, 555.55g, 99% bromobenzene to intermediate 1, raise the temperature to 20-50°C, add dropwise 203.50g, 98% water-absorbing agent, stir and react for 2-5 hours, the reaction is complete, and lower the temperature by 20°C Next, add 370.00 g of...

Embodiment 3

[0045] Step 1, the preparation of intermediate 1:

[0046] Put 185.00g of 40% glyoxylic acid into the reaction kettle, dehydrate under the condition of 40-80℃ / -0.095MPa for 1-2 hours, add 310.00g of toluene to reflux with water until it is basically anhydrous (control moisture below 0.5%), and cool down Add 6.20g of acidic catalyst to 20-50°C, raise the temperature, add 65.00g of 99% isopropanol dropwise under reflux, return with water, control glyoxylic acid below 0.5%, cool to 20-50°C, add 200.00 g of washing water, phase separation, and desolventization of the organic phase to obtain 115.00 g of 98% isopropyl glyoxylate, namely intermediate 1.

[0047] Step 2, the preparation of intermediate 2:

[0048] Add 6.25g Lewis acid, 400.00g, 99% bromobenzene to intermediate 1, raise the temperature to 20-50°C, add dropwise 200.00g, 98% water-absorbing agent, stir and react for 2-5 hours, the reaction is complete, and lower the temperature by 20°C Next, add 350.00 g of washing wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com