Dispersing agent and method for improving magnetic performance of bonded permanent magnetic ferrite material

A technology of bonding permanent magnets and dispersants, which is applied in the direction of inorganic material magnetism, magnetic materials, magnetic objects, etc., and can solve the problem of low magnetic performance, low impact strength, and difficulty in multi-pole magnetization of bonded permanent magnet ferrite. problem, to achieve the effect of increasing Zeta potential, preventing particle agglomeration, and improving magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

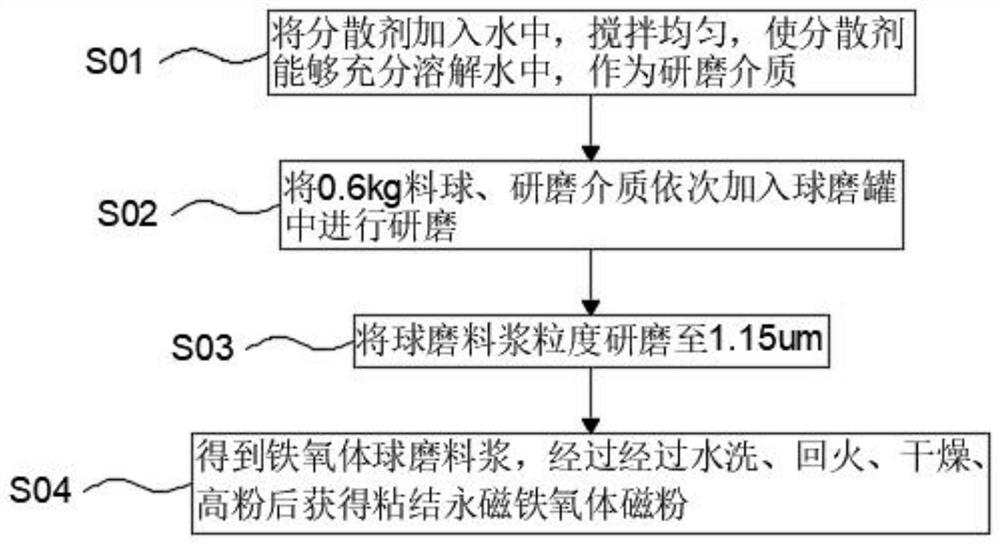

[0029] refer to figure 1 A method for improving the dispersant of the magnetic properties of bonded permanent ferrite materials comprises the following steps:

[0030] S01: Add the dispersant to 1L of water, stir evenly, so that the dispersant can be fully dissolved in water, as a grinding medium, wherein the weight of calcium gluconate is 0.4% of the calcined ball, and the ratio of sodium polyacrylate to calcium gluconate is 3: 1;

[0031] S02: add 0.6 kg of material balls and grinding media into the ball mill tank in turn for grinding;

[0032] S03: Grinding the particle size of the ball mill slurry in step S2 to 1.15um;

[0033] S04: The ferrite ball grinding slurry obtained in step S3 is washed with water, tempered (920° C.), dried, and powdered to obtain bonded permanent ferrite magnetic powder.

[0034] The following table shows the process parameters and test results of permanent ferrite magnetic properties:

[0035]

[0036]

[0037] It can be seen from the a...

Embodiment 2

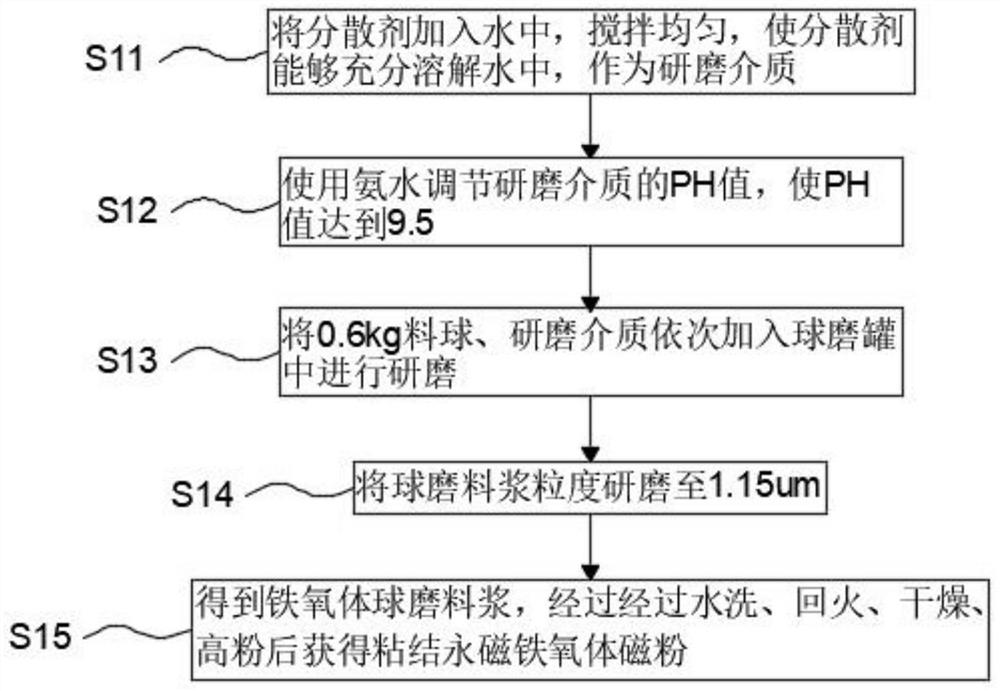

[0039] refer to figure 2 A method of improving the dispersant of the magnetic properties of bonded permanent ferrite materials also includes the following steps:

[0040] S11: Add the dispersant to 1L of water, stir evenly, so that the dispersant can be fully dissolved in water, as a grinding medium, wherein the weight of calcium gluconate is 0.4% of the calcined ball, and the ratio of sodium polyacrylate to calcium gluconate is 3: 1;

[0041] S12: Use ammonia water to adjust the pH value of the grinding medium to make the pH value reach 9.5;

[0042] S13: adding 0.6 kg of material balls and grinding media to the ball mill tank in turn for grinding;

[0043] S14: Grinding the particle size of the ball mill slurry in step S13 to 1.15um;

[0044] S15: The ferrite ball grinding slurry obtained in step S14 is washed with water, tempered, dried, and powdered to obtain bonded permanent ferrite magnetic powder.

[0045] The following table shows the process parameters and test r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com