Anaerobic fermentation co-extrusion degradation bag and preparation method thereof

A technology of anaerobic fermentation and extrusion temperature, applied in the field of plastic bags, can solve the problems of non-degradable and slow degradation of plastic bags, and achieve the effect of low degradation threshold, good toughness and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

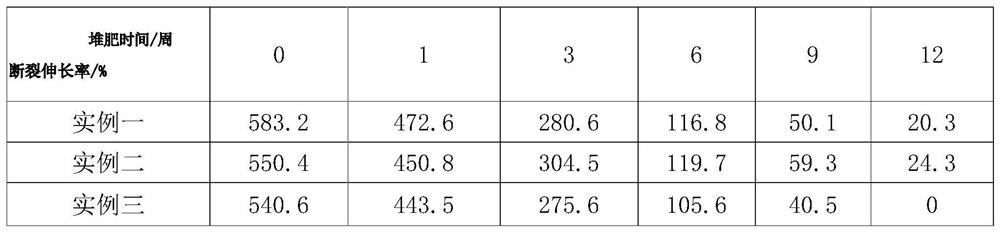

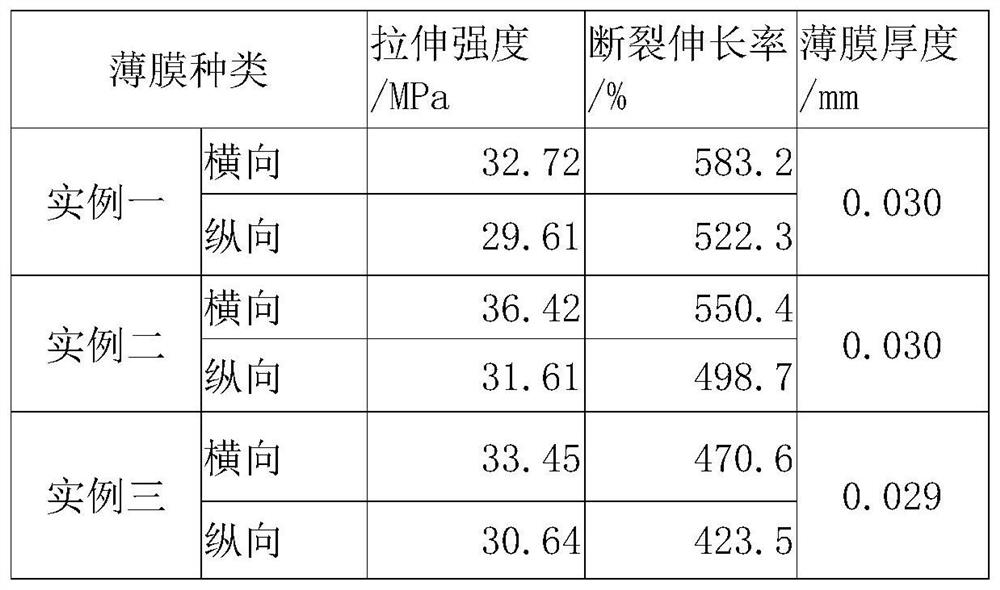

example 1

[0021] First, the mass parts are: 100 parts of polybutylene adipate terephthalate, 40 parts of polylactic acid, and 60 parts of thermoplastic starch resin are added to a high-speed mixer and stirred at room temperature for 20 minutes. After mixing evenly, the material is discharged, and the mixture is added to In a twin-screw extruder, extrude and granulate at 140°C-180°C. Then, 100 parts of modified PVA were dried in a blast drying oven at 60° C. for 5 hours. Then the dried modified PVA is added to the middle layer extruder hopper of the three-layer co-extrusion blown film machine, and the mixture is respectively added to the outer layer and the inner layer extruder funnel of the three-layer co-extrusion blown film machine, and extruded at the same time, The extrusion temperature of the outer layer is 110°C-130°C, the middle layer is made of water-soluble degradation material, the extrusion temperature is 125°C-160°C, the inner layer extrusion temperature is 110°C-130°C, at 1...

example 2

[0023] First, the mass parts are: 110 parts of polybutylene adipate terephthalate, 50 parts of polylactic acid, and 40 parts of thermoplastic starch resin are added to a high-speed mixer and stirred at room temperature for 20 minutes. After mixing evenly, the material is discharged, and the mixture is added to In a twin-screw extruder, extrude and granulate at 140°C-180°C. Then, 100 parts of modified PVA were dried in a blast drying oven at 60° C. for 5 hours. Then the dried modified PVA is added to the middle layer extruder hopper of the three-layer co-extrusion blown film machine, and the mixture is respectively added to the outer layer and the inner layer extruder funnel of the three-layer co-extrusion blown film machine, and extruded at the same time, The extrusion temperature of the outer layer is 110°C-130°C, the middle layer is made of water-soluble degradation material, the extrusion temperature is 125°C-160°C, the inner layer extrusion temperature is 110°C-130°C, at 1...

example 3

[0025] First, the mass parts are: 120 parts of polybutylene adipate terephthalate, 60 parts of polylactic acid, and 20 parts of thermoplastic starch resin are added to a high-speed mixer and stirred at room temperature for 20 minutes. After mixing evenly, the material is discharged, and the mixture is added to In a twin-screw extruder, extrude and granulate at 140°C-180°C. Then, 100 parts of modified PVA were dried in a blast drying oven at 60° C. for 5 hours. Then the dried modified PVA is added to the middle layer extruder hopper of the three-layer co-extrusion blown film machine, and the mixture is respectively added to the outer layer and the inner layer extruder funnel of the three-layer co-extrusion blown film machine, and extruded at the same time, The extrusion temperature of the outer layer is 110°C-130°C, the middle layer is made of water-soluble degradation material, the extrusion temperature is 125°C-160°C, the inner layer extrusion temperature is 110°C-130°C, at 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com