Production and assembling equipment for TST-PVC floor

A technology of TST-PVC and assembling equipment, which is applied to the device, coating, and pretreatment surface of the surface coating liquid, which can solve the problems of difficult adjustment and transformation, single equipment performance, low floor efficiency, etc., to save adjustment. Time, simple and compact structure, high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

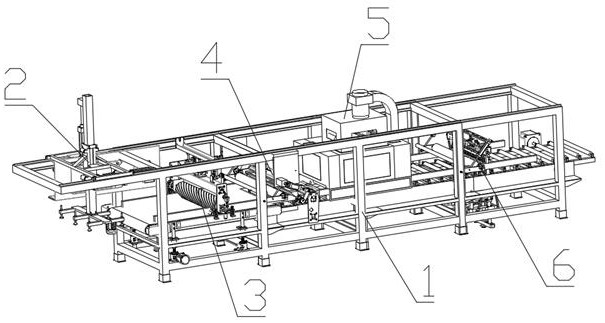

[0032] Embodiment 1: as figure 1 As shown, a production and assembly equipment for TST-PVC flooring includes a conveyor frame 1, a feeding device 2, a printing device 3, a coating device 4, a drying device 5 and a cutting device 6, and the conveyor frame 1 includes a main frame , conveying roller, baffle plate and driving motor, the feeding device 2 sends the product to the printing device 3 for printing, and then the printing device 3 sends the product to the conveying roller, and the conveying roller conveys the product to the coating device 4, The drying device 5 and the cutting device 6 respectively carry out the coating of UV paint, the drying of UV paint and the cutting of the floor, and then the conveying roller continues to convey and discharge the cut product, and the conveying roller is driven by the driving motor to rotate .

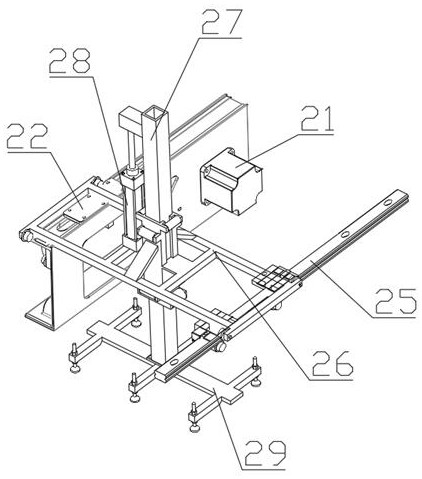

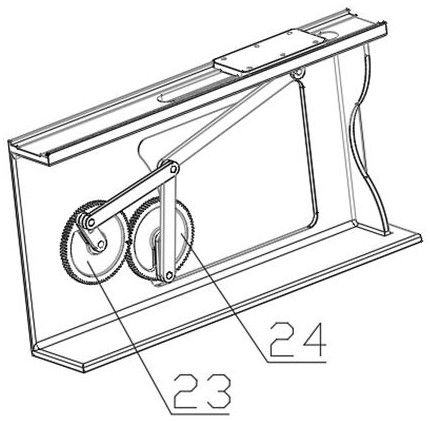

[0033] Firstly, the material is loaded by the feeding device 2, such as figure 2 with image 3 As shown, the feeding device 2 includes a ...

Embodiment 2

[0038] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in order to realize the production and assembly of floors of different thicknesses, such as Figure 4 As shown, the printing device 3 is also provided with four worm-gear elevators 39 below the belt conveyor 37. The four worm-gear elevators 39 are driven by servo motors and can precisely adjust the height of the lift, thereby controlling the height of the belt conveyor 37. And cooperate with the adjustment cylinder 36 to drive the printing roller 381 to move up and down, which can satisfy the printing on the bottom plate of various thicknesses; correspondingly, as Image 6 with Figure 7 As shown, the compression cylinder 413 of the first compression assembly 41 drives the compression roller 412 to move up and down, and then adjusts the height of the compression roller 412 to adapt to compacting floors of different thicknesses. The thickness adjustment cylinder of the coating device 4 42 can ...

Embodiment 3

[0039] Embodiment 3: The difference between this embodiment and embodiment 1 is that in order to realize the UV coating of different widths to the bottom plate, as Image 6 with Figure 7 As shown, the coating device 4 is also provided with an adjustment rack 47, a gear box 48 and a rubber baffle 49, and the paint tank 43 is divided into a plurality of paint chambers. Drive the gears in the gear box 48 to rotate through the servo motor, thereby driving the gear box 48 to slide on the adjustment rack 47, and then driving the rubber baffles 49 to move back and forth, adjusting the distance between the two rubber baffles 49 to meet the needs The width of the coating enables the UV paint to be coated on the floor between the two rubber baffles 49; by adjusting the rubber baffles 49, coatings of different widths are realized, which further improves the compatibility of the equipment and reduces the equipment cost. the cost of.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com