Novel rack of cold stamping forming machine and corresponding cambered-surface blade cold stamping forming machine

A new type of frame and forming machine technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of loose structure, long production cycle and large floor area of cold stamping forming machines, and shorten the production cycle , low cost, and the effect of reducing the equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

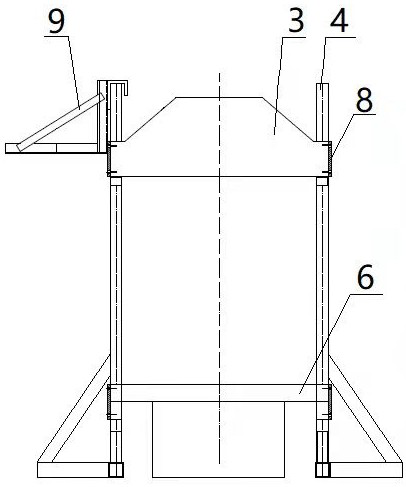

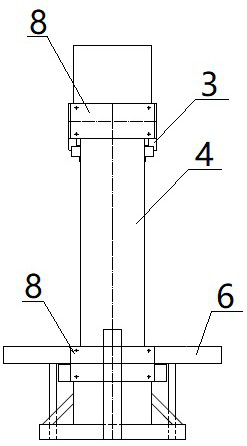

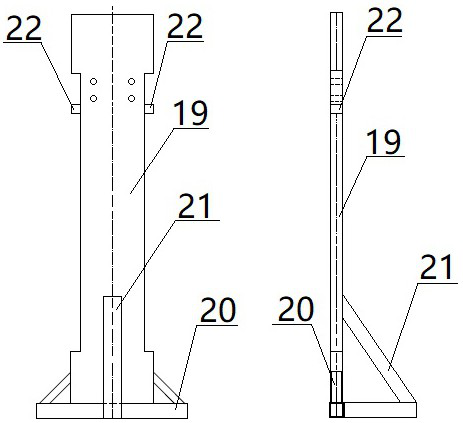

[0023] A new frame (referred to as: new rack), including cylinder seat 3, rack column 4, mold platform 6, pedestal stable plate 8, pump station side bracket 9; innovative overall implementation plan YES: (1) Simplify the cylinder bracket structure: Improve the four-column cylinder bracket into two partial columns, double tilt column 4 can be used for oil cylinder seat 3 and the mold platform 6 sharing, simple structure; (2) Improvement of the machine: Casting The machine is improved to the weld mold platform 6, which is simple and reduced by weight; (3) Optimize the whole machine structure: add the pump station side bracket 9 on the rack, place the hydraulic pump station, and install the control cabinet 7 in the rack On the column 4, it is convenient to use, and the dispersion type cold press molding machine is used to integrated cold punching molding machine, the structure is compact; the specific embodiment will be described in detail below.

[0024] The cylinder holder 3 is a r...

Embodiment 2

[0031] A curved blade cold press molding machine (referred to as a press molding machine), using the new type of rack (referred to as: new rack) provided by the present invention; the stamping body, the stamping mechanism, a new type The rack, control cabinet 7, composed; stamping mechanism, including hydraulic pump station 1, punching cylinder 2; stamping cylinder 2, including the cylinder piston rod 10 and the stamping disc 11, the stamping disk 11 has corresponding installation with the mold 5 Hole; new rack, including cylinder holder 3, double tilt 4, mold platform 6, pedestal stable plate 8, pump station side bracket 9; control cabinet 7 is provided with rising, lower pressure, pause, etc. The blade stamping die 5 is used in conjunction with the function of the arc blade of the stamped molding mixer. The present invention is manufactured in accordance with the technical part of the prior art, in accordance with the conventional hydraulic pumping station 1, the pressing cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com