Tab flattening method of all-tab cylindrical lithium batteries

An all-tab, lithium battery technology, applied to battery pack parts, circuits, electrical components, etc., can solve problems such as product quality impact, short circuit, lower product qualification rate and safety performance, and improve the qualification rate and safety performance , The effect of eliminating the influence of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention will be described in detail below according to the above-mentioned drawings.

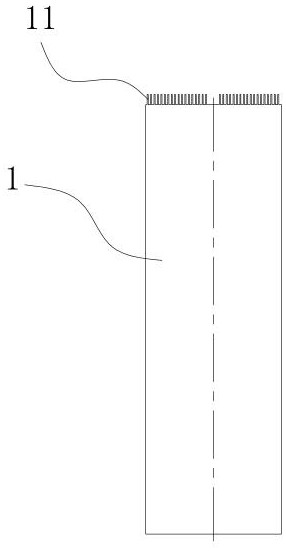

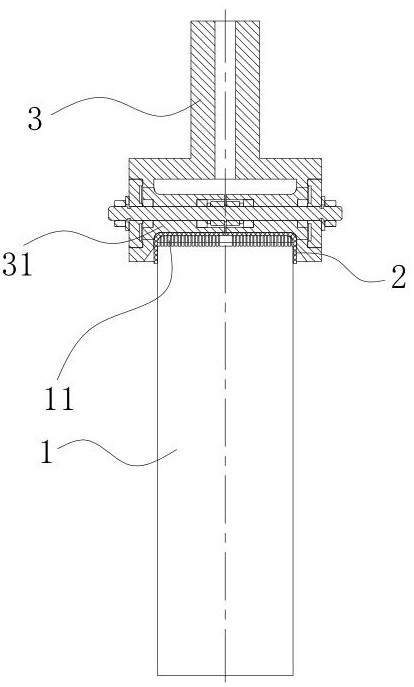

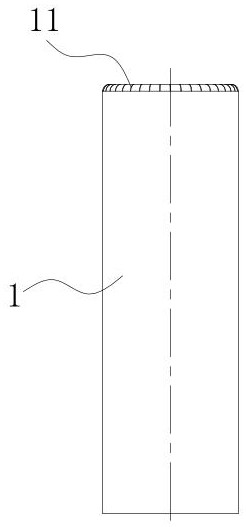

[0022] Such as Figure 1~Figure 5 As shown, 1. winding battery core, 11. full pole ear, 2. kneading flat sleeve, 21. inner chamfering, 3. kneading flat head, 31. kneading flat roller.

[0023] A tab flattening method for a full-tab cylindrical lithium battery, which is a kneading method that can effectively prevent the soft full tab part from being crushed, and the operation steps are as follows:

[0024] Step 1. Transport the wound battery cell 1 of the cylindrical lithium battery that has been processed to the kneading machine. The two ends of the wound battery cell have full tabs 11 respectively, and the full tabs 11 at each end are kneaded correspondingly. The kneading head of the machine 3;

[0025] Step 2. Knead the flat sleeve 2 on the outer cover of the full pole ear 11. The kneaded flat sleeve can be automatically inserted in combination wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com