Pretreatment method and device for social source hazardous waste incineration residues

A pretreatment device and hazardous waste technology, applied in the direction of grain processing, solid waste removal, etc., can solve the constraints of the social source hazardous waste incineration residue cannot be fed continuously at high temperature, lack of systematic pretreatment process of hazardous waste incineration residue Hazardous waste incineration residue application and other issues to achieve the effect of reducing energy consumption, reducing equipment damage, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with specific examples, so that those skilled in the art can better understand the present invention and implement it, but the given examples are not intended to limit the present invention.

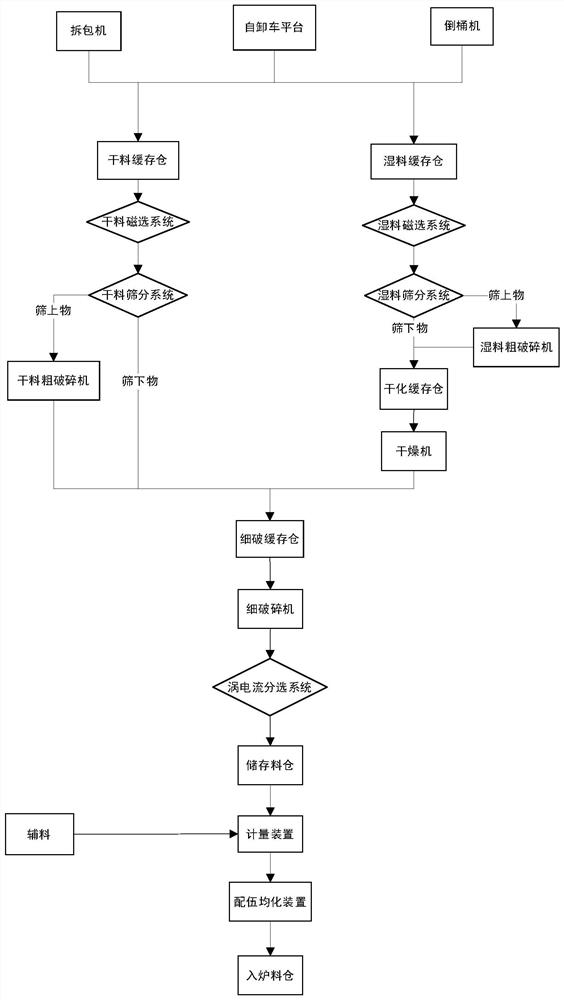

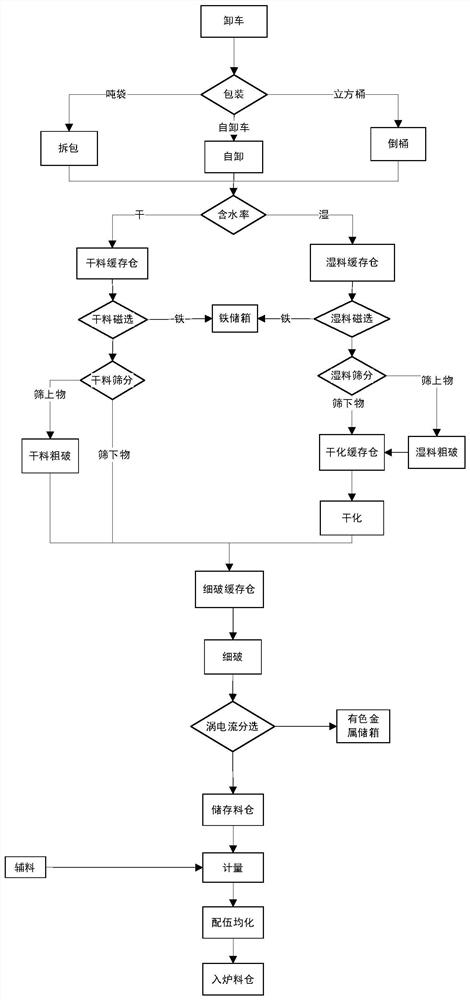

[0045] Such as figure 1 A pretreatment device for hazardous waste incineration residue from social sources is shown, the pretreatment device includes a discharge system, a dry material treatment system, a wet material treatment system, a fine crushing buffer bin, a fine crusher, an eddy current sorting system, a storage Material silo, metering device, compatibility homogenizing device and furnace feeding silo.

[0046] The unloading system includes an unpacking machine, a bucket dumping machine and a car dump platform. According to the different packaging forms of materials, unpacking, dumping barrels and loading bulk materials into dump trucks are used for unloading. Ton bag packaging is suitable for unpacking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com