Flatness control method and device, and coating film forming method and device

A control method and a technology of a control device, which are applied in the direction of bonding methods, film/sheet adhesives, photoplate-making process coating equipment, etc., can solve problems such as uneven processing, and achieve the effect of reducing the variation of coating film thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0200] In Example 1, the flatness of the wafer was controlled by the following procedure.

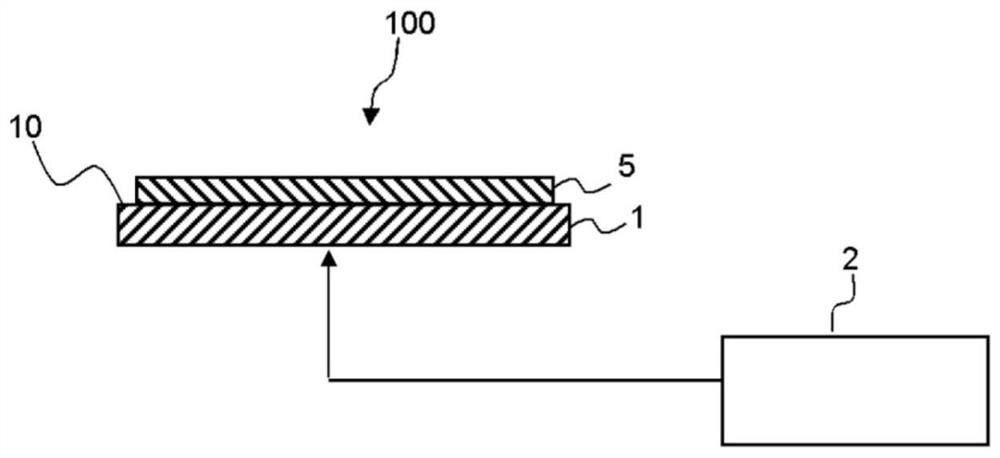

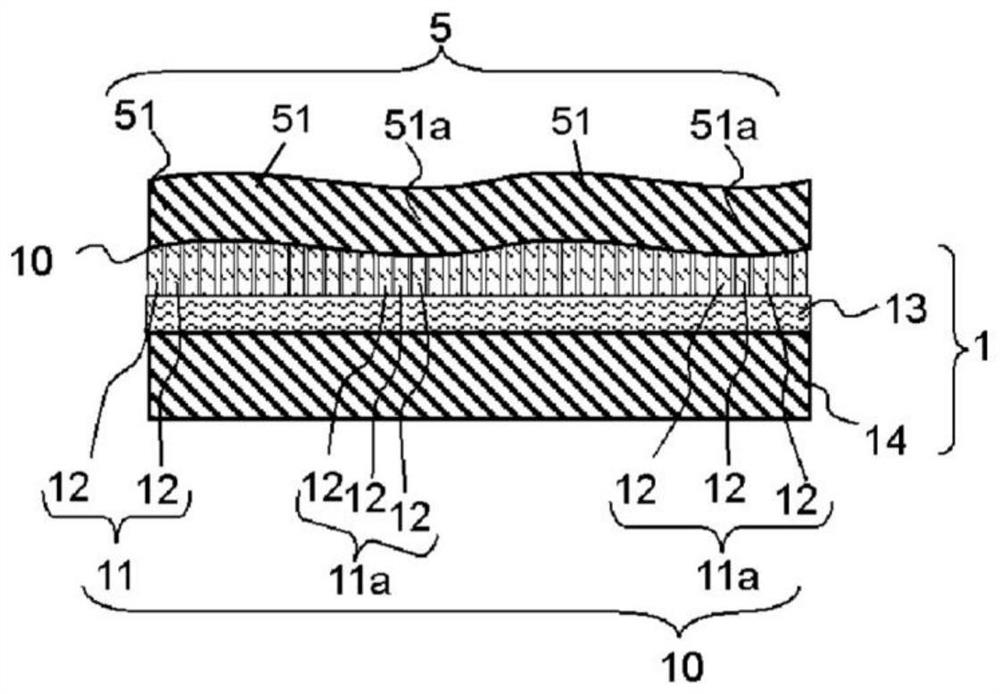

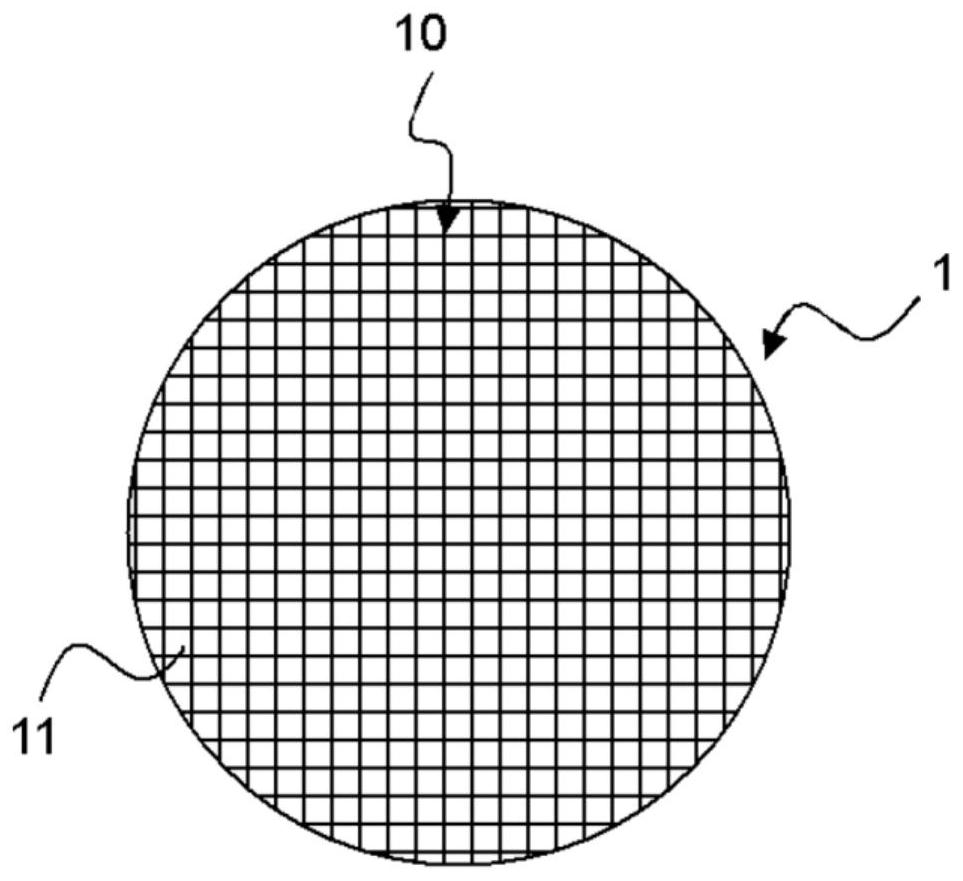

[0201] First, prepare and Figure 1 ~ Figure 3 The same flatness control device 100 is shown. The holding surface 10 includes configurations such as image 3 A thousand segments 11 of a checkerboard grid are shown. Also, the dry adhesive fibrous structure 12 of the holding member 1 has Figure 5 The shape shown roughly.

[0202] Next, the wafer 5 to be controlled is prepared. Wafer 5 contains a thousand silicon wafers of divided regions 51 .

[0203] Such as figure 2 As shown, the wafer 5 is adsorbed on the holding surface 10 of the holding member 1 , and the wafer 5 is held on the holding member 1 .

[0204] In this state, the flatness of each of the divided regions 51 of the wafer 5 is measured, and information on the flatness is acquired. The flatness of wafer 5 was 0.4 microns.

[0205] Next, the controller 2 judges, among the plurality of divided regions 51 of the wafer 5...

Embodiment 2

[0208] In Example 2, the flatness of the wafer was controlled in the same procedure as in Example 1 except for the following points.

[0209] In the second embodiment, the flatness information of the wafer 5 is obtained by measuring the flatness before being held by the holding member 1 , and based on this information, the flatness is controlled in the same manner as in the first embodiment. The flatness of the wafer 5 held in front of the holding member 1 is 0.01 μm. Also, in Example 2, the same wafer 5 as that in Example 1 was used.

[0210] The flatness of the wafer 5 whose flatness is controlled in Example 2 is 0.01 μm.

Embodiment 3

[0212] In Example 3, on the wafer 5 whose flatness was controlled in Example 1, a photoresist film was formed by the following procedure.

[0213] Such as Figure 7 As shown, the wafer 5 whose flatness has been controlled is held by the holding member 1 , and is fixed by the vacuum chuck 4 .

[0214] Next, the test coating film-forming composition was coated on the wafer 5 in this state using the coating device 6 . A photoresist was used as the composition for test coating film formation.

[0215] Next, it baked at 100 degreeC, and formed the photoresist film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com