Environment-friendly coating construction process for indoor wall surface

A construction technology and technology for interior walls, applied in covering/lining, construction, building construction, etc., can solve the problems of waste of materials, prone to mildew on walls, etc., to reduce the amount of materials, improve construction efficiency, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings.

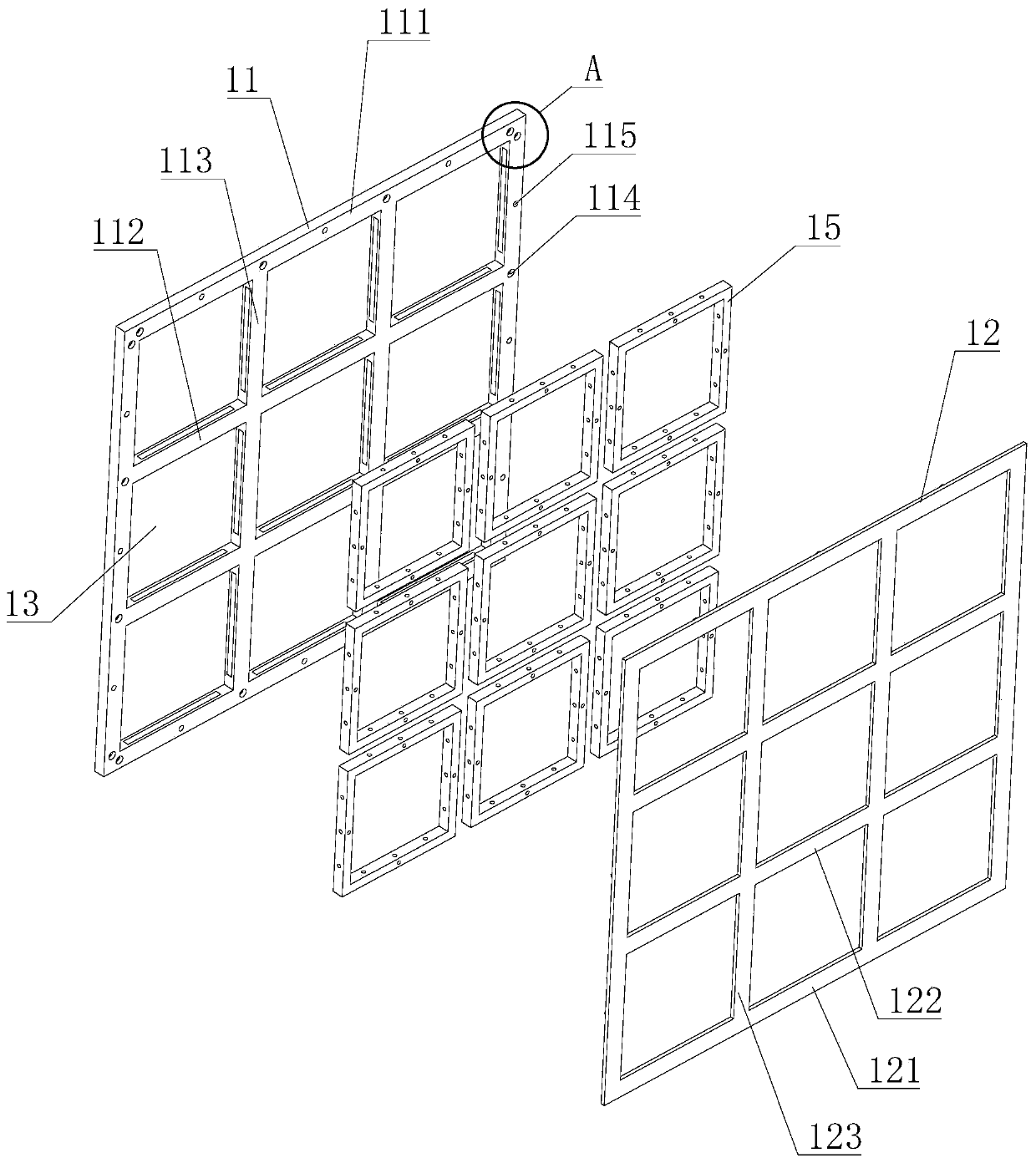

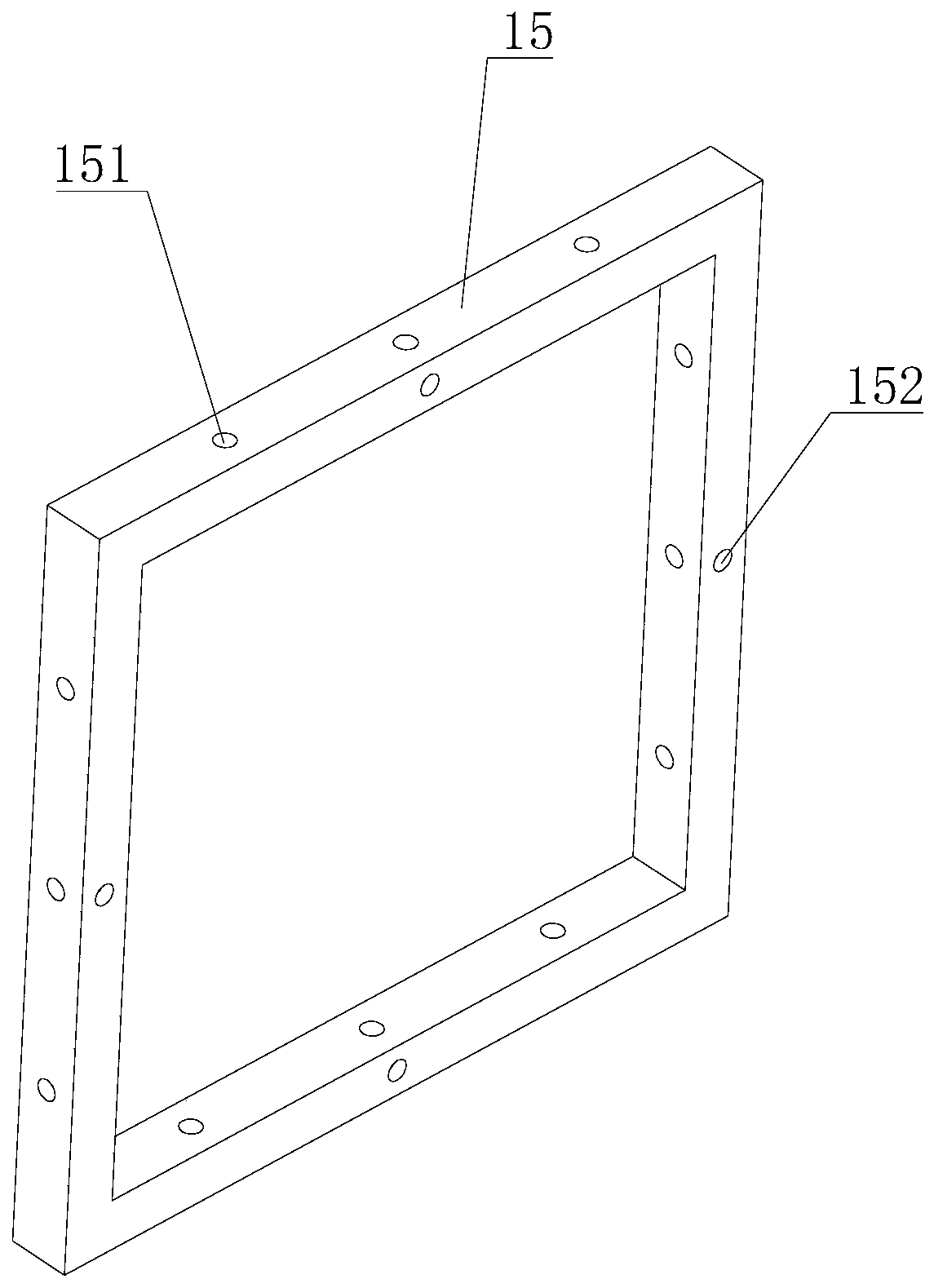

[0045] See attached figure 1 , a skeleton member 1, which is applied to the construction technology of indoor wall surface green painting, includes an inner skeleton 11 and an outer skeleton 12 stacked in sequence.

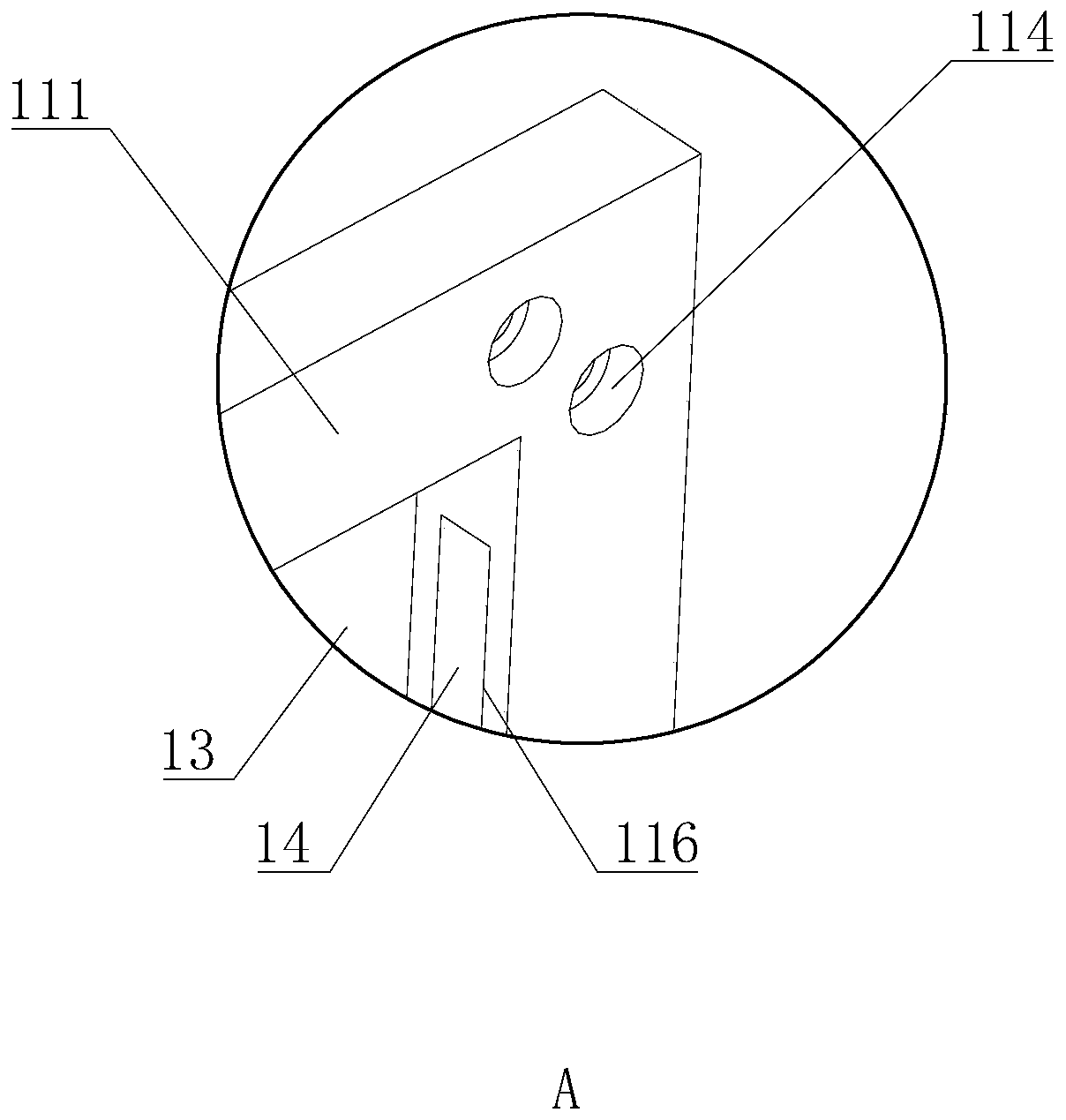

[0046] The inner frame 11 includes an inner frame body 111 , two inner transverse ribs 112 and two inner vertical ribs 113 . The inner frame body 111 is a rectangular frame. The two inner transverse ribs 112 are arranged horizontally, and the two ends of each inner transverse rib 112 are respectively connected to the left and right side walls of the inner circle of the inner frame body 111 . The two inner vertical ribs 113 are arranged vertically, and the two ends of each inner vertical rib 113 are respectively connected to the upper and lower side walls of the inner circle of the inner frame body 111 . The cross sections of the inner frame bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com