Harmless treatment method for retired lithium battery pyrolysis tail gas

A harmless treatment, lithium battery technology, applied in the direction of lithium batteries, chemical instruments and methods, separation methods, etc., can solve the problems of low value of recycled products, complicated treatment process, difficult practical application, etc., to achieve easy control and amplification, The effect of simple process and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

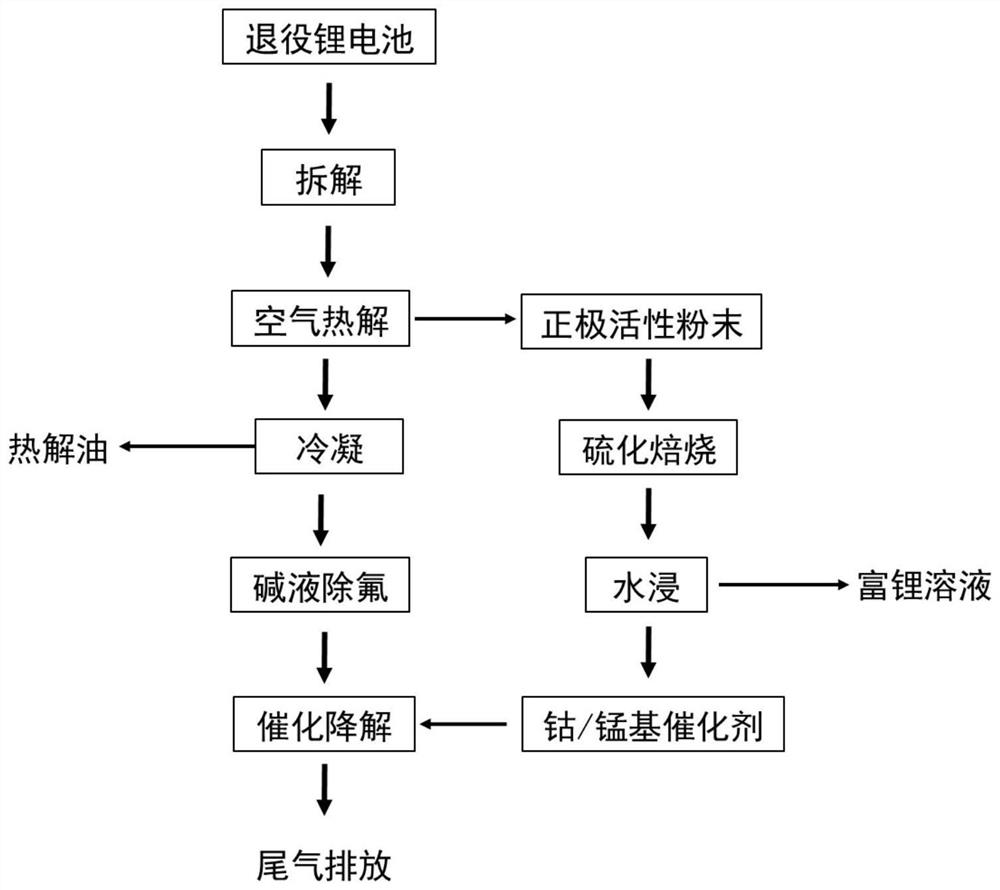

Image

Examples

Embodiment 1

[0025] Perform air pyrolysis on the decommissioned nickel-cobalt-lithium manganese oxide battery material obtained by discharging and dismantling, mix the positive electrode active powder in the pyrolyzed material with potassium pyrosulfate at a mixing mass ratio of 1:2, and then roast at 700°C. The roasted product is leached in pure water at room temperature with a solid-to-liquid ratio of 50g / L, and filtered to obtain a solid cobalt / manganese-based catalyst; the tail gas discharged from pyrolysis is condensed to recover the pyrolysis oil, and then passed through the calcium hydroxide solution to intercept the fluorine in the tail gas compounds; the tail gas after alkali treatment is passed into a fixed-bed catalytic oxidation reactor filled with 60 mg of cobalt / manganese-based catalyst at 50 ml / min for catalytic degradation treatment at 200 ° C.

Embodiment 2

[0027] Perform air pyrolysis on the decommissioned lithium manganate battery material obtained by discharging and dismantling, mix the positive electrode active powder and sulfuric acid in the pyrolyzed material evenly at a mixing mass ratio of 4:1, and then roast at 750°C, and then roast the roasted product with Solid-to-liquid ratio 100g / L, pure water leaching treatment at room temperature, filtration to obtain solid manganese-based catalyst; tail gas discharged from pyrolysis is condensed to recover pyrolysis oil, and then passed through sodium hydroxide solution to intercept fluoride in the tail gas; lye treatment The final tail gas is passed into a fixed-bed catalytic oxidation reactor filled with 80 mg of cobalt / manganese-based catalyst at 70 ml / min for catalytic degradation treatment at 250° C.

Embodiment 3

[0029] The decommissioned lithium cobalt oxide battery material obtained by discharging and dismantling was subjected to air pyrolysis, the positive electrode active powder in the pyrolysis material was mixed with sodium pyrosulfate at a mixing mass ratio of 1:3, and then roasted at 600°C, and the roasted product was Solid-to-liquid ratio 50g / L, pure water leaching treatment at room temperature, and filtration to obtain solid cobalt-based catalyst; tail gas discharged from pyrolysis is condensed to recover pyrolysis oil, and then passed through calcium hydroxide solution to intercept fluoride in tail gas; lye treatment The final tail gas is passed into a fixed-bed catalytic oxidation reactor filled with 90 mg of cobalt-based catalyst at 80 ml / min for catalytic degradation treatment at 150° C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com