Method for reducing content of silicon dioxide in chlor-alkali primary brine

A silica and brine technology, which is applied in material analysis by observing the effect on chemical indicators, and analysis by chemical reaction of materials, etc. The problem of rising costs, etc., to achieve the effect of reducing the cost of solid waste treatment, low addition of magnesium chloride, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment is used to illustrate the method for reducing the silicon dioxide content in chlor-alkali primary brine of the present invention.

[0048] Take the saturated brine of the chemical salt tank of the chlor-alkali plant, and use the aforementioned method to measure the concentration of silicon dioxide to be 26.73 mg / L;

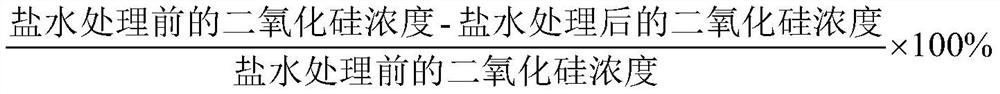

[0049] Take 1000mL of saturated brine from the chemical salt tank of the above-mentioned chlor-alkali device, adjust the pH value to 9.0, put the brine in a water bath at 30°C, add a magnetic stirrer to the brine, and keep stirring. After the temperature of the brine reaches 30°C, add 100g / L magnesium chloride Solution 3.0mL, then add 6.0mL of 100g / L sodium carbonate solution, start timing, after 20 minutes, centrifuge the brine at a speed of 10000rpm and take the supernatant to measure the concentration of silicon dioxide. The silicon dioxide concentration measured by the aforementioned method was 23.36 mg / L, and the single-pass silicon dioxi...

Embodiment 2

[0051] This embodiment is used to illustrate the method for reducing the silicon dioxide content in chlor-alkali primary brine of the present invention.

[0052] Take 1000mL of the same saturated brine as in Example 1, adjust the pH value to 11.6, put the brine in a water bath at 50°C, add a magnetic stirrer to the brine, and keep stirring. After the temperature of the brine reaches 50°C, add 100g / L magnesium chloride solution 6.0mL, then add 3.0mL of 100g / L sodium carbonate solution, and start timing. After 60 minutes, centrifuge the brine at a speed of 10000rpm and take the supernatant to measure the concentration of silicon dioxide. The concentration of silicon dioxide measured by the aforementioned method is 7.58mg / L, the calculated one-way silica removal rate is 71.6%.

Embodiment 3

[0054] This embodiment is used to illustrate the method for reducing the silicon dioxide content in chlor-alkali primary brine of the present invention.

[0055] Take 1000mL of the same saturated brine as in Example 1, adjust the pH value to 11.6, put the brine in a water bath at 70°C, add a magnetic stirrer to the brine, and keep stirring. After the temperature of the brine reaches 70°C, add 100g / L magnesium chloride solution 1.0mL, then add 3.0mL of 100g / L sodium carbonate solution, and start timing. After 30 minutes, filter the brine with a 0.22μm microporous membrane and take the filtrate to measure the concentration of silicon dioxide. The concentration of silicon dioxide measured by the above method is 14.31mg / L, the calculated one-way silica removal rate is 46.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com