A three-step construction technology based on a tunnel excavation and support integrated trolley

A technology of tunnel excavation and construction technology, which is applied in the direction of tunnels, tunnel linings, shaft equipment, etc., which can solve problems such as high use and maintenance costs, expensive equipment, and single functions, and achieve improved construction quality, high degree of automation, and safety. The effect of high coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below with reference to the accompanying drawings and embodiments.

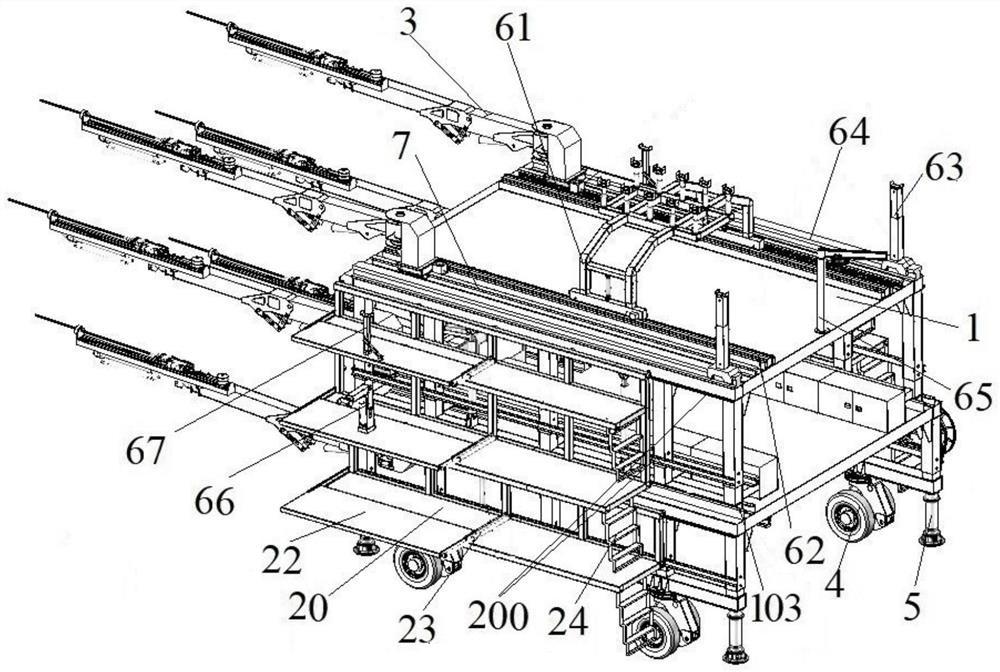

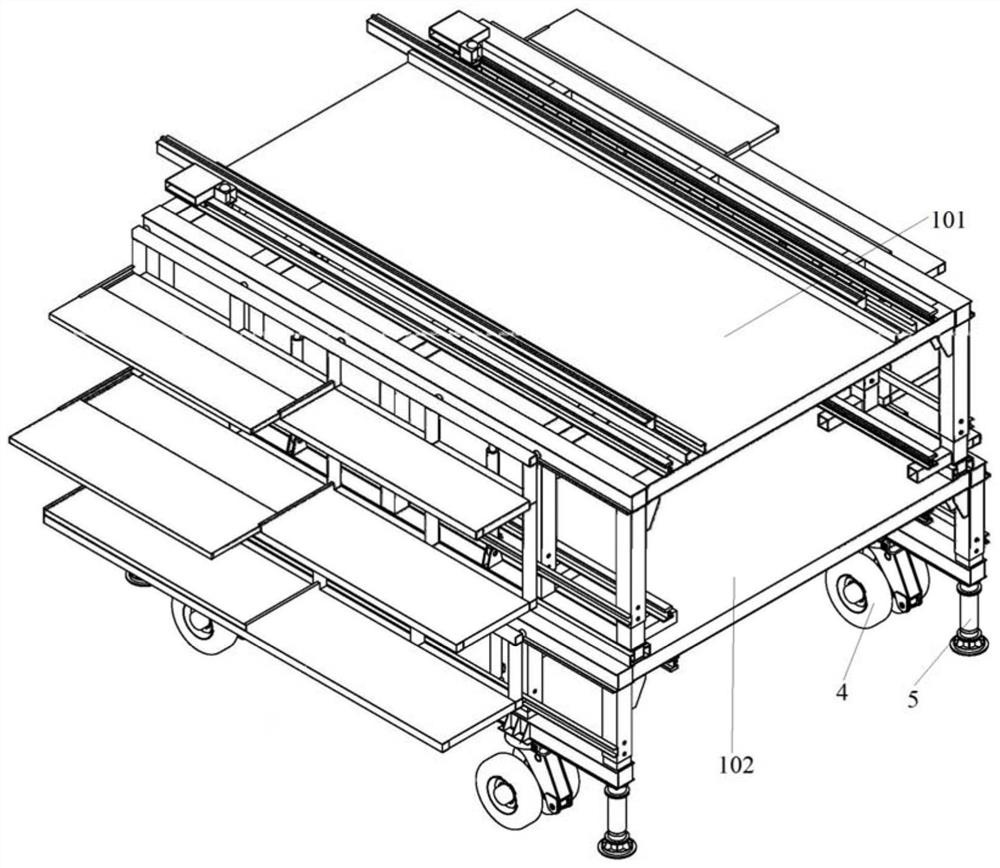

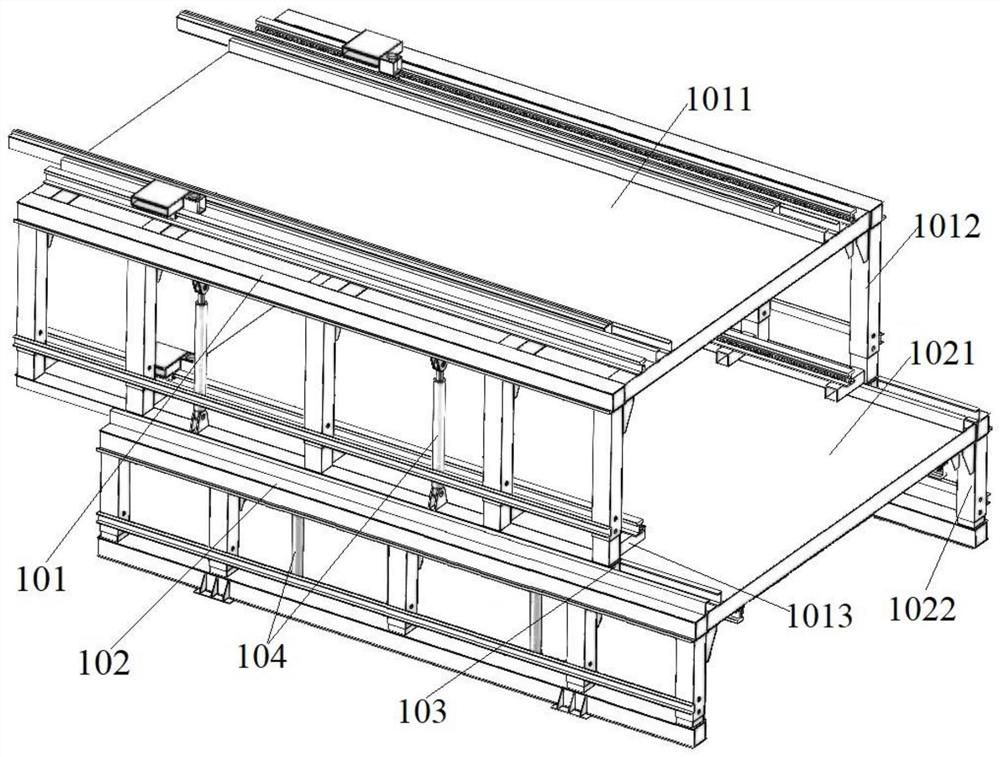

[0064] The overall structure of the tunnel excavation and support integrated trolley provided in this embodiment is as follows: figure 1 and figure 2 As shown in the figure, it includes a car body, an electro-hydraulic system located on the car body that provides operating power for each component on the trolley, a working arm 3 for tunnel excavation and support construction, a running mechanism 4 connected to the bottom of the car body, and The support mechanism 5 and the arch frame installation unit, wherein the vehicle body includes a platform 1 and a working platform 20 . The integrated trolley can realize the integration of drilling and blasting, charging, arch pre-installation, bolt hole, bolt installation grouting, arch mesh installation, milling operation, concrete wet spraying operation, etc. It is suitable for tunnel construction of various c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com