Rotary compressor, refrigerating circulation and ice house using same

A rotary compressor and compressor technology, applied in the field of refrigerators, can solve the problems of sliding and reliability reduction of the guide groove 17, instability at the moment of movement, and increased sliding loss, so as to avoid the concentration of load and prevent sliding Loss, effect to prevent rise in temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

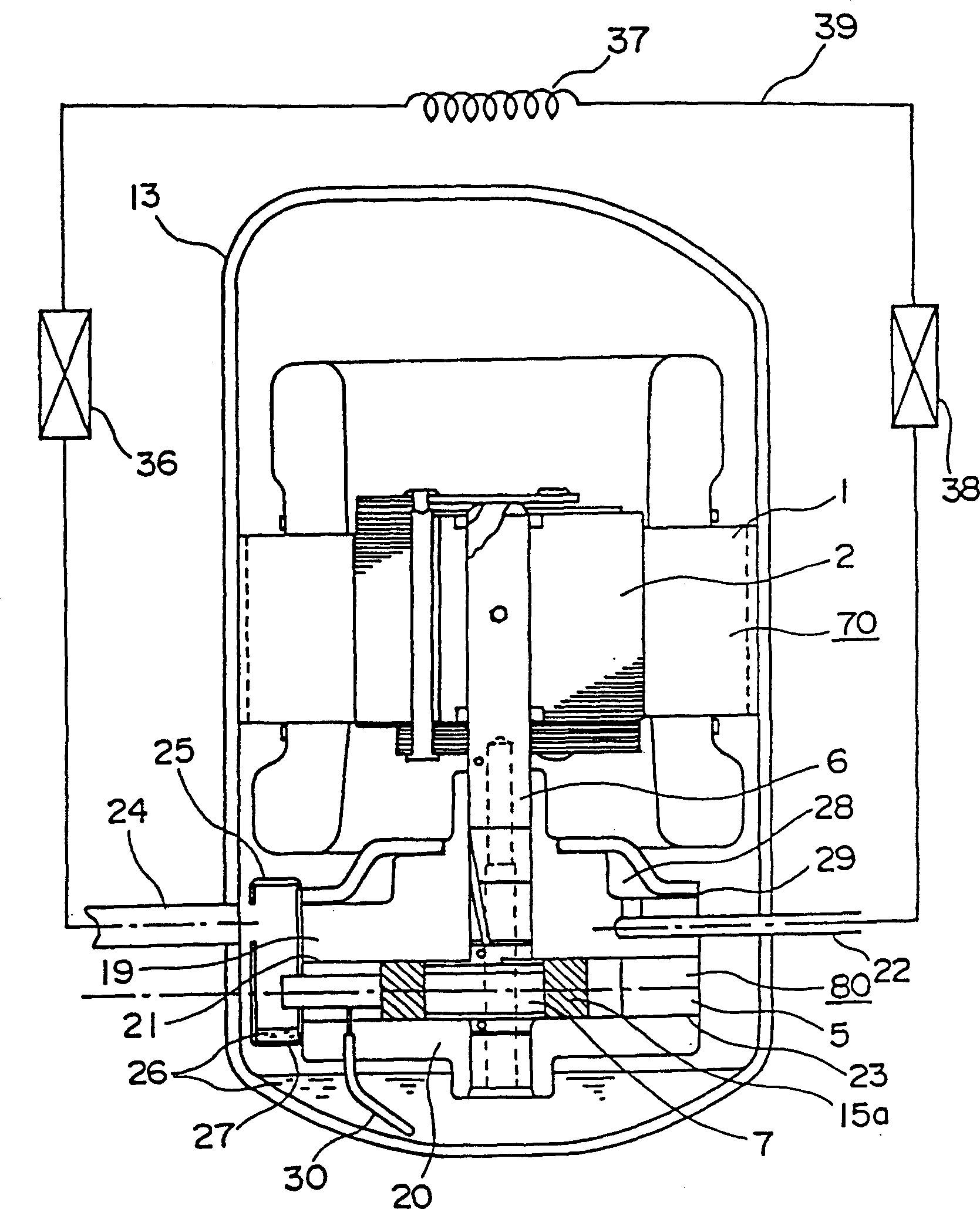

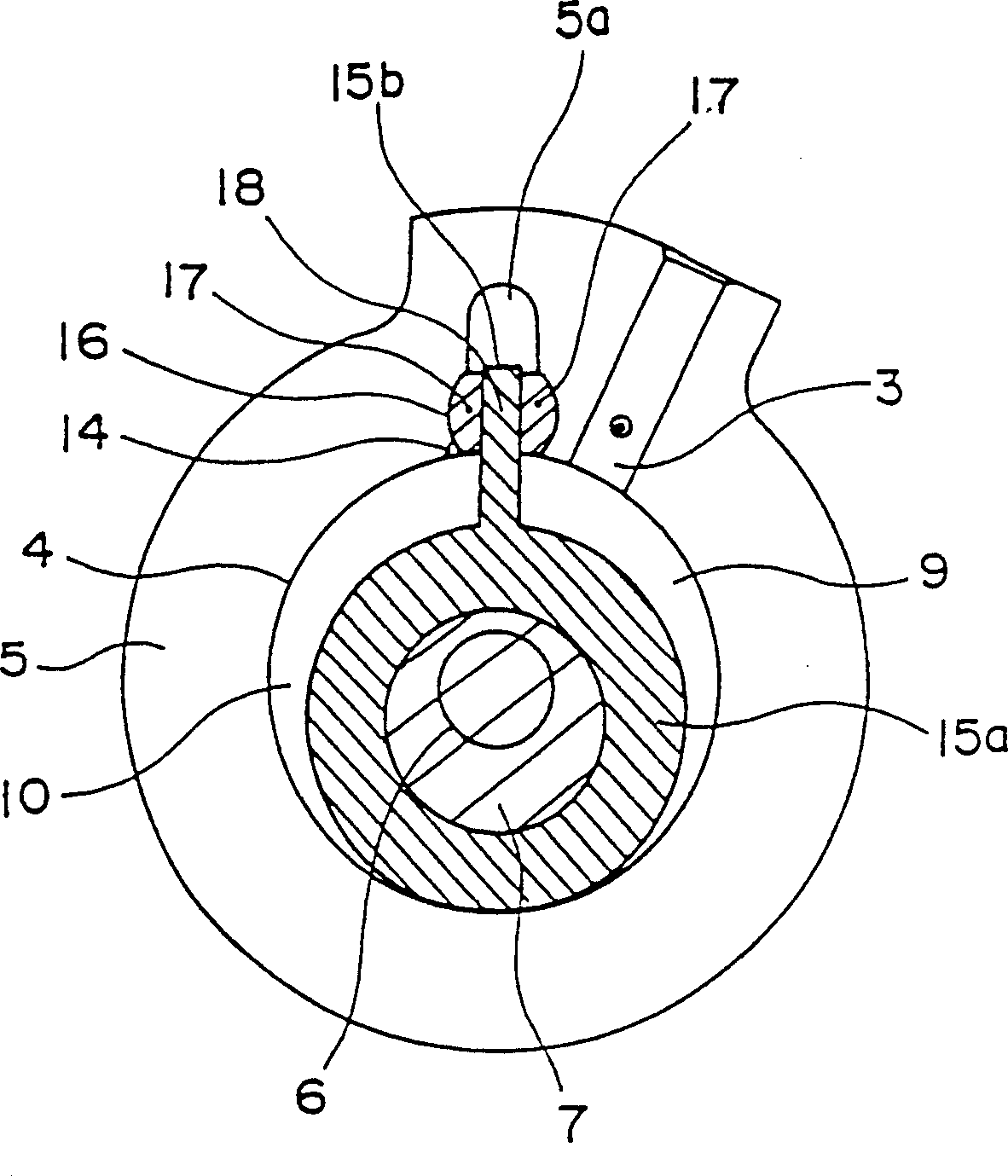

[0068] figure 1 It is a vertical sectional view and a refrigeration cycle diagram of a vane-integrated piston type rotary compressor in an embodiment of the present invention, figure 2 It is a cross-sectional view of the compression mechanism part of the same compressor.

[0069] In the figure, the vane-integrated piston type rotary compressor includes a motor unit 70 composed of a stator 1 and a rotor 2 , and a compression mechanism unit 80 driven by the motor unit 70 . Compression mechanism part 80 comprises: cylinder 5, and it has a cylinder room 4, and suction port 3 and discharge port 14 are opened on this cylinder room 4; 7 and can freely rotate around it; the blade 15b divides the cylinder chamber 4 designed as one with the piston 15a into two parts: the low-pressure chamber 9 communicated with the suction port 3 and the high-pressure chamber 10 communicated with the discharge port 14; the guide groove 17, is embedded in the cylindrical hole 16 formed in the cylinde...

Embodiment approach 2

[0083] In this embodiment, the same parts as those in the first embodiment are denoted by the same symbols, and their descriptions are omitted, and only the characteristic parts of this embodiment will be described. Fig. 4A is a longitudinal sectional view of the vane-integrated piston type compressor of the present embodiment, showing elastic support members; Fig. 4B is a longitudinal sectional view and refrigeration cycle diagram of the same compressor of the present embodiment, showing the suction path and spit out the path. In FIGS. 4A and 4B , the vane-integrated piston type compressor includes a motor unit 70 composed of a stator 1 and a rotor 2 , and a compression mechanism unit 80 driven by the motor unit 70 . and in Embodiment 1 figure 2 The same as shown, the compression mechanism part 80 includes: a cylinder 5, which has a cylinder chamber 4, the suction port 3 and the discharge port 14 are opened on the cylinder chamber 4; the piston 15a is installed in the above...

Embodiment approach 3

[0092] Embodiment 3 of the present invention will be described below. The vane-integrated piston type rotary compressor in this proposal is a vane-integrated piston type rotary compressor constructed as in Embodiment 1 and Embodiment 2, wherein HFC-based refrigerants such as R134a are used as refrigerants.

[0093] In the vane-integrated piston type rotary compressor constituted according to the above scheme, since the airtight container is a suction pressure atmosphere, there is no high-temperature and high-pressure gas refrigerant flowing from the contact surface between the cylinder and the frame and the contact surface between the cylinder and the cylinder head, The phenomenon of reverse flow to the low-pressure side equipped with the evaporator, so that there is no need to specially set a check valve in the circuit to prevent the temperature rise of the cooler during the running gap. In addition, since the vane is integrated with the piston, problems such as failure to st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com