A process for preparing porous structure on the surface of tc4 titanium alloy by electrochemical dealloying

A technology of porous structure and dealloying method, which is applied in the field of biomedical materials, can solve problems such as insufficient surface osteogenic activity, poor internal osseointegration, human injury, etc., and achieve good induction of bone regeneration, improvement of osseointegration performance, and avoiding shedding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Step 1. Add 10 mL of concentrated nitric acid solution with a mass concentration of 68% into 400 mL of deionized water, stir and mix, then add 5 mL of hydrogen peroxide with a mass concentration of 30%, stir and mix, and then add 85 mL of deionized water to prepare a mixed solution ;

[0038] Step 2: Polish the TC4 titanium alloy with a specification of 10mm×10mm×1mm (length×width×thickness) with 800#, 1000#, 1500# and 2000# sandpaper in turn until the surface has no obvious scratches visible to the naked eye, Then, acetone, ethanol and deionized water were used for ultrasonic cleaning for 15 min respectively, and then placed in an oven for drying at 60° C. for 30 min, and vacuum sealed for use; the acetone and ethanol were both analytically pure reagents;

[0039] Step 3. The mixed solution obtained in step 1 is placed in an electrochemical device as an electrolyte, the TC4 titanium alloy after drying in step 2 is placed in the electrolyte as an anode, a platinum elect...

Embodiment 2

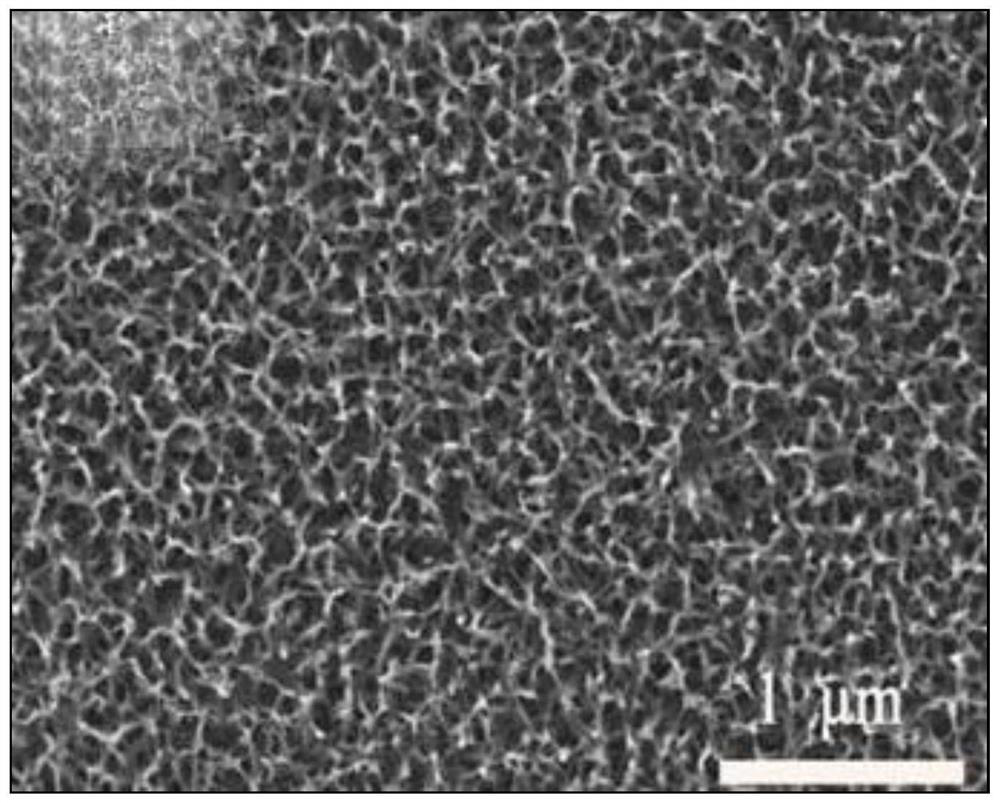

[0058] The difference between this example and Example 1 is that: in step 1, 5 mL of concentrated nitric acid solution with a mass concentration of 68% was added to 492 mL of deionized water and stirred and mixed, and then 3 mL of hydrogen peroxide with a mass concentration of 30% was added and stirred and mixed. ; The corrosion voltage used in the electrochemical dealloying treatment in step 3 is 1.0V, the time is 45min, the micron-scale pores with a pore diameter of 300 μm are formed on the surface of the TC4 titanium alloy, and the thickness of the porous structure in the TC4 titanium alloy with a porous structure on the surface is formed. is 2 μm.

Embodiment 3

[0060] The difference between this example and Example 1 is that: in step 1, 10 mL of concentrated nitric acid solution with a mass concentration of 68% was added to 487.5 mL of deionized water, stirred and mixed, and then 2.5 mL of hydrogen peroxide with a mass concentration of 30% was added and stirred Mix well; in step 3, the corrosion voltage used in the electrochemical de-alloying treatment is 1.0V, and the time is 60min, and a micron-scale porous structure with a pore diameter of 400 μm is formed on the surface of the TC4 titanium alloy, and the surface has a porous structure in the TC4 titanium alloy. The thickness is 2 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com