Polyamine with inhibiting and solid-phase cleaning effects as well as preparation method and application thereof

A polyamine-based technology, applied in the preparation of carboxylic acid amide, preparation of organic compounds, chemical instruments and methods, etc., can solve problems such as wellbore instability, high-temperature drilling fluid solid-phase cleaning effect needs to be improved, etc., to ensure well Wall stability, good inhibitor solid-phase cleaning effect, and the effect of ensuring the cleaning of drilling fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

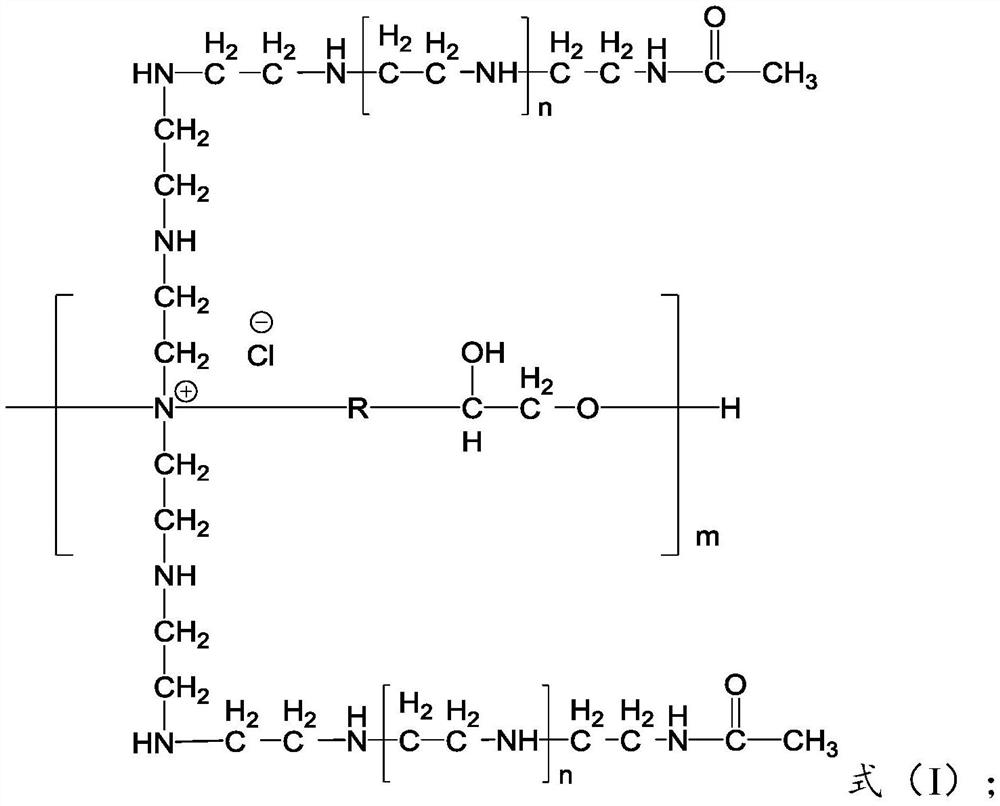

[0031] The present invention also provides a method for preparing the above-mentioned polyamine having both inhibition and solid-phase cleaning functions, comprising: S1) mixing and heating a halogenated epoxide, water and an acidic catalyst to obtain a haloalcohol solution; S2) Mix and heat the haloalcohol solution with polyethylene polyamine to obtain an intermediate product I; S3) mix and heat the intermediate product I with dihalogenated ethane to obtain an intermediate product II; S4) convert the intermediate The product II is mixed with polyethylene polyamine and heated to react to obtain the intermediate product III; S5) adding acetic acid to the intermediate product III, and heating to cause a chain termination reaction to obtain a polyamine having both inhibitory and solid-phase cleaning functions.

[0032] Among them, the present invention has no special limitation on the sources of all raw materials, which can be commercially available.

[0033] Mix and heat the hal...

Embodiment 1

[0043] Add 38g of epichlorohydrin, 60g of water and 4g of concentrated sulfuric acid into the reaction kettle, control the stirring speed at 500r / min, and react at a temperature of 85°C for 0.5h to obtain a chlorohydrin solution; add 70g of four Ethylenepentamine, react at a temperature of 60°C for 1.0h to obtain an intermediate product I; add 40g of dichloroethane to the intermediate product I, and react at a temperature of 80°C for 2.0h to obtain an intermediate product II; add to the intermediate product II 140g of tetraethylenepentamine was reacted at a temperature of 70°C for 2.0h to obtain the intermediate product III; 50g of acetic acid was added to the intermediate product III and reacted at a temperature of 50°C for 0.5h, a chain termination reaction occurred to obtain a reddish-brown viscous transparent Liquid, that is, a polyamine that combines inhibition and solid-phase cleaning. The product yield is 93.42%.

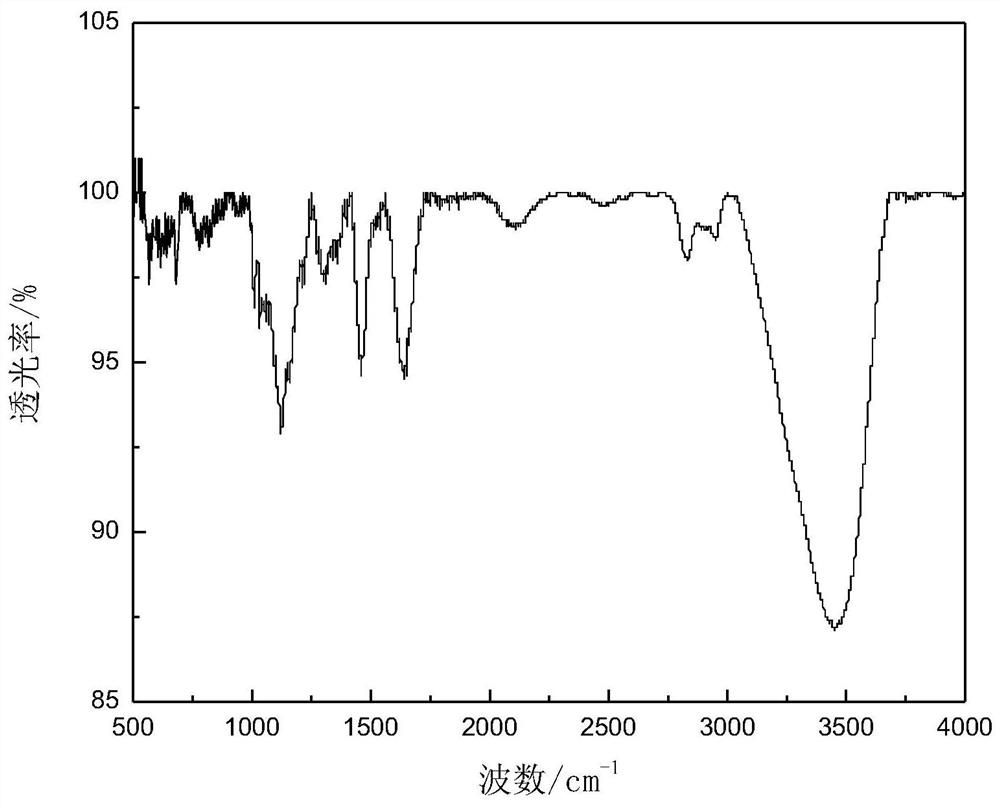

[0044] The polyamine prepared in Example 1 of the pres...

Embodiment 2

[0049] Add 38g of epichlorobutane, 80g of water and 5g of concentrated hydrochloric acid into the reactor, control the stirring speed at 700r / min, and react at a temperature of 90°C for 1.0h to obtain a chlorohydrin solution; add 80g of chlorohydrin to the above chlorohydrin solution Tetraethylenepentamine, react at a temperature of 70°C for 2.0h to obtain an intermediate product I; add 50g of dichloroethane to the intermediate product I, and react at a temperature of 90°C for 3.0h to obtain an intermediate product II; in the intermediate product II Add 160g of tetraethylenepentamine, react at 80°C for 3.0h to obtain intermediate product III; add 60g of acetic acid to intermediate product III, react at 60°C for 1.0h, a chain termination reaction occurs, and a reddish-brown viscous product is obtained Transparent liquid, that is, polyamine with both inhibitory and solid-phase cleaning effects. The product yield is 92.87%.

[0050] The polyamine prepared in Example 2 of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com