Catalytic ozonation reactor for sewage treatment

A technology for ozone oxidation and sewage treatment, applied in water/sewage treatment, oxidized water/sewage treatment, water/sewage treatment equipment, etc. The problem of high residual ozone concentration in the gas phase can achieve the effect of complete oxidation reaction of organic matter, solve the loss of copper metal, and reduce the probability of free radical recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] Preparation of Catalyst A1 (Fe-Ce / Al 2 o 3 )

[0025] The macroporous alumina powder and peptizer are kneaded, rolled, and extruded to make a clover-shaped carrier with a diameter of 2.5 mm, and then calcined at 550 ° C in the air to obtain Al 2 o 3 Carrier, specific surface area 220 m 2 / g, pore volume 0.7 cm 3 / g, the average pore diameter is 10.4nm. Weigh 500g of alumina carrier, according to its water absorption with Fe(NO 3 ) 3 9H 2 O and Ce(NO 3 ) 3 ·6H 2 O by Fe 2 o 3 and CeO 2 Accounting for 5% and 1.5% of the total weight of the catalyst respectively, they are formulated into solutions. The alumina carrier was impregnated with an equal volume of Fe-Ce solution for 2 hours, dried at 80°C, then calcined in a muffle furnace at 550°C for 4 hours, and taken out after the temperature dropped to room temperature to obtain catalyst A1.

[0026] Preparation of Catalyst A2 (Fe-Ce / ZSM-5)

[0027] The diameter is 2.0mm, the specific surface area is 320m 2 / ...

Embodiment 1

[0033] In the tertiary biochemical effluent of an oil refinery sewage treatment plant, COD=56 mg / L, BOD=1 mg / L, SS=8 mg / L, the COD that can be directly oxidized by ozone is 15 mg / L, which can be The COD of further catalytic oxidation was 18 mg / L.

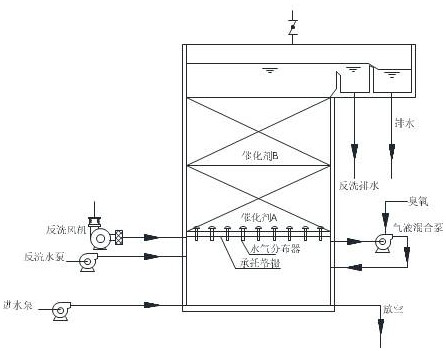

[0034] A sewage treatment ozone catalytic oxidation reactor, such as figure 1 shown. Sewage enters the gas-liquid mixing pump (3) through the water inlet pipe (1), fully mixes and dissolves with the ozone from the ozone generator (2), and then enters the direct ozone oxidation zone (4). The volume of the direct oxidation zone accounts for 1 / 2 of the total volume . During the reaction process, the dosage of ozone is 90 mg / L, and the catalytic oxidation zone (5) is filled with catalyst A1 and catalyst B1 in sequence, and the volume ratio of the two catalysts is 40% and 60%. The space velocity of the reactor is 1.0 h -1 , the air washing intensity during backwashing is 5 L / m 2 s, the washing strength is 4 L / m 2 s, in the process ...

Embodiment 2

[0037] In the secondary biochemical effluent of a chemical sewage treatment plant, COD=65 mg / L, BOD=0.5 mg / L, SS=15 mg / L, the COD that can be directly oxidized by ozone is 12 mg / L, which can be The COD of further catalytic oxidation was 23 mg / L.

[0038] A sewage treatment ozone catalytic oxidation reactor, such as figure 1 shown. Sewage enters the gas-liquid mixing pump (3) through the water inlet pipe (1), fully mixes and dissolves with the ozone from the ozone generator (2), and then enters the ozone direct oxidation zone (4). The volume of the direct oxidation zone accounts for 1 / 3 of the total volume . During the reaction process, the dosage of ozone is 35 mg / L, and the catalytic oxidation zone (5) is filled with catalyst A1 and catalyst B2 in sequence, and the volume ratio of the two catalysts is 50% and 50%. The space velocity of the reactor is 3.0 h -1 , the air washing intensity during backwashing is 15 L / m 2 s, the washing strength is 10 L / m 2 s, in the process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com