Method for rapidly cleaning insoluble dirt in oil wells and oil reservoirs close to oil wells

An insoluble scale, oil well technology, applied in wellbore/well components, chemical instruments and methods, cleaning appliances, etc., can solve problems such as chemical incompatibility, oil well bore, ground blockage, production hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

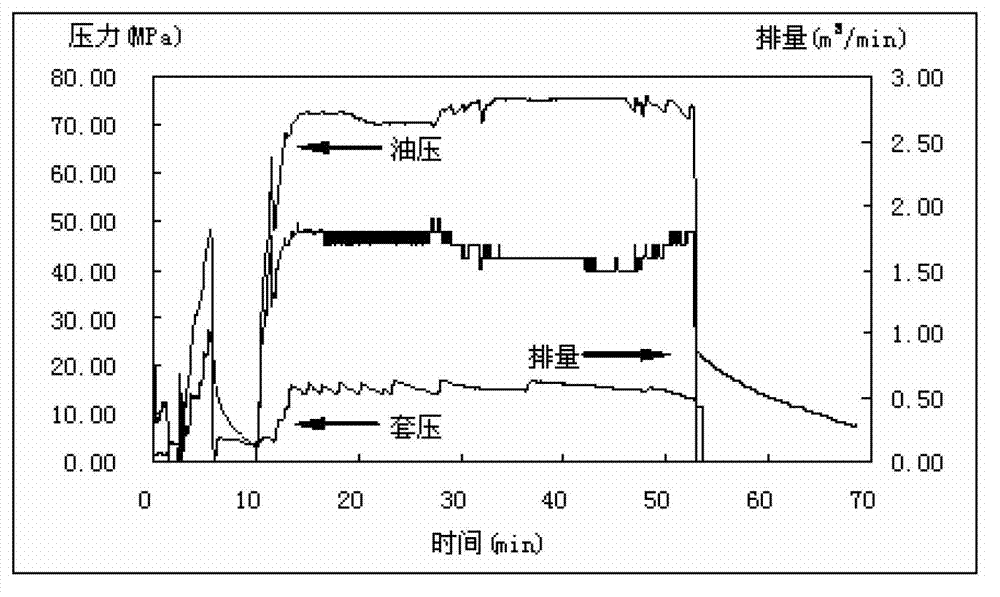

Image

Examples

Embodiment 1

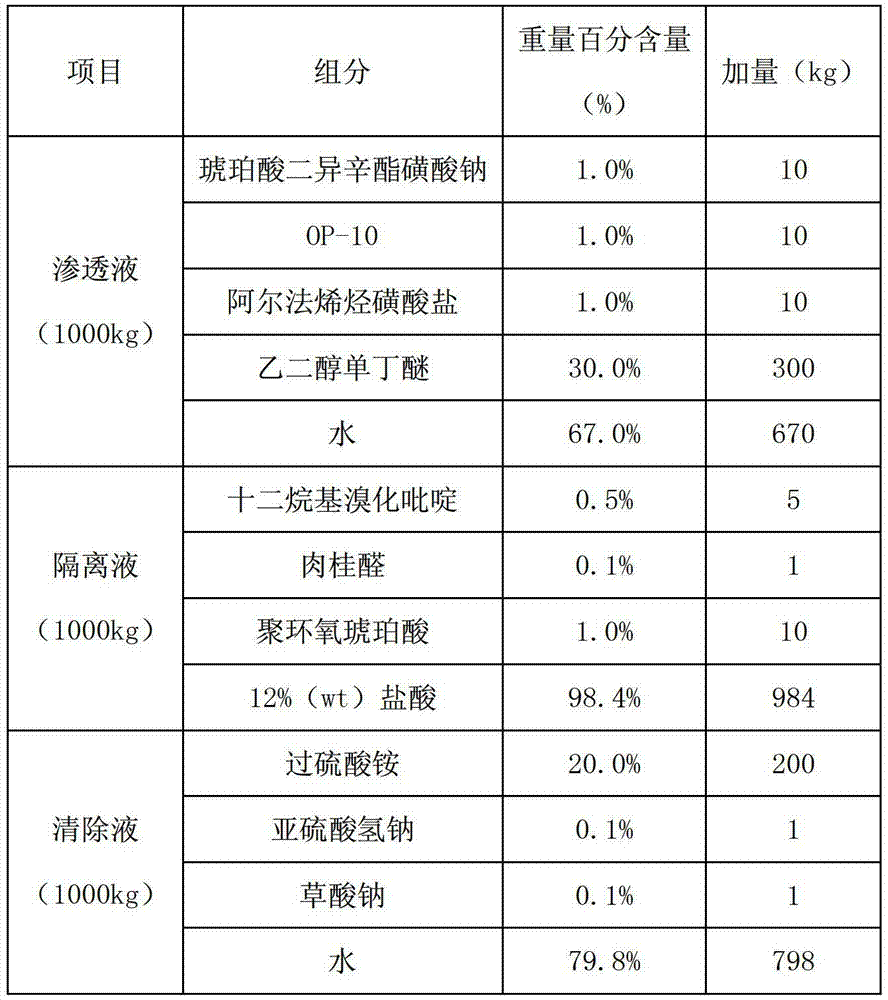

[0026] (1) Formula

[0027] Table 1 Embodiment 1 formula composition

[0028]

[0029] (2) Preparation method

[0030] Permeate (prepared 1000kg):

[0031] ①Add 670kg of distilled water to a container with a stirring device; ②Add 300kg of ethylene glycol monobutyl ether under constant stirring; ③Add 10kg of OP-10, and stir until it dissolves; ④Add 10kg of diisooctyl sodium sulfosuccinate Stir to dissolve evenly; ⑤Finally add 10kg of alpha olefin sulfonate and stir until the solution is uniform.

[0032] Spacer fluid (prepared 1000kg):

[0033] ①Prepare 984kg of hydrochloric acid with 12% weight concentration in the acid tank with stirring device; ②Add 5kg of dodecyl pyridinium bromide under constant stirring; ③Add 10kg of polyepoxysuccinic acid and stir until it dissolves; ④Add 1kg of cinnamaldehyde, stirring continuously until the cinnamaldehyde dissolves evenly.

[0034] Cleaning solution (prepared 1000kg):

[0035] ①Add 798kg of distilled water to a container with ...

Embodiment 2

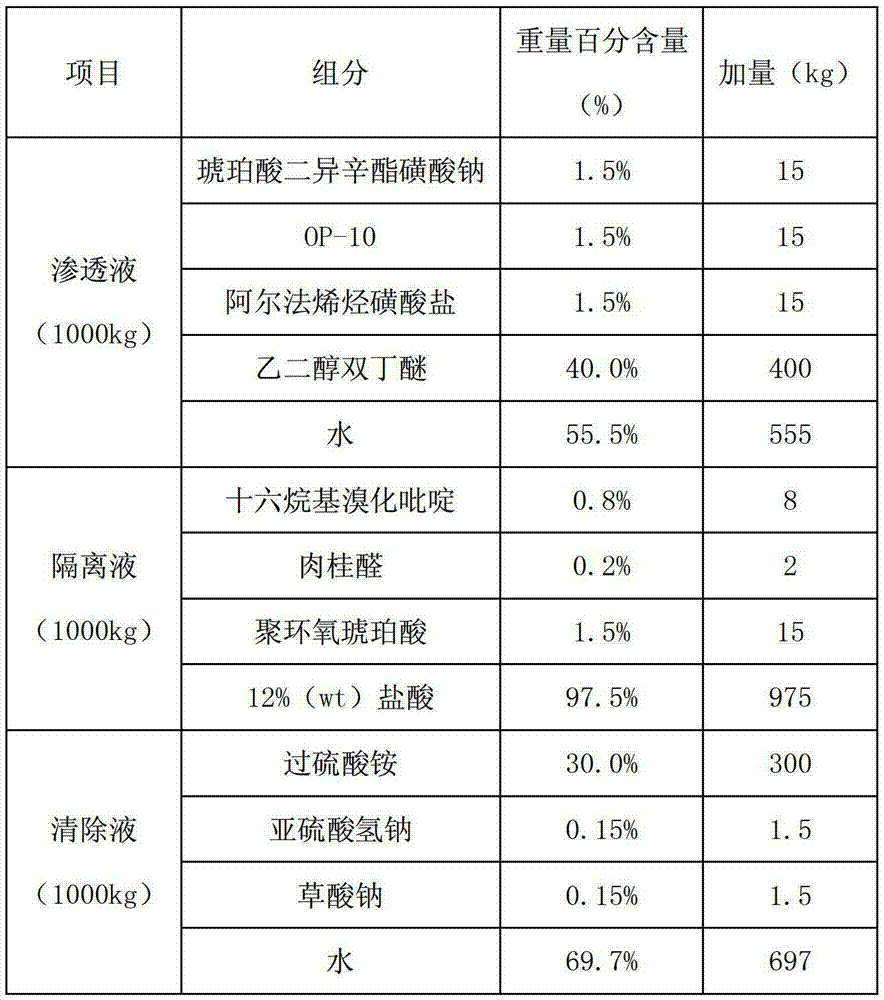

[0037] (1) Formula

[0038] Table 2 embodiment 2 formula composition

[0039]

[0040] (2) Preparation method

[0041] Permeate (prepared 1000kg):

[0042] ①Add 555kg of distilled water to a container with a stirring device; ②Add 400kg of ethylene glycol monobutyl ether under continuous stirring; ③Add 15kg of OP-10 and stir until it dissolves; ④Add 15kg of diisooctyl sodium sulfosuccinate Stir to dissolve evenly; ⑤Finally add 15kg of alpha olefin sulfonate and stir until the solution is uniform.

[0043] Spacer fluid (prepared 1000kg):

[0044] ①Prepare 975kg of hydrochloric acid with a concentration of 12% by weight in an acid tank with a stirring device; ②Add 8kg of cetylpyridinium bromide under continuous stirring; ③Add 15kg of polyepoxysuccinic acid and stir until it dissolves; ④Add 2kg of cinnamaldehyde, stirring constantly, until the cinnamaldehyde dissolves evenly.

[0045] Cleaning solution (prepared 1000kg):

[0046] ①Add 697kg of distilled water to a contain...

Embodiment 3

[0048] (1) Formula

[0049] Table 3 Embodiment 3 formula composition

[0050]

[0051] (2) Preparation method

[0052] Permeate (prepared 1000kg):

[0053] ①Add 440kg of distilled water to a container with a stirring device; ②Add 500kg of ethylene glycol monobutyl ether under continuous stirring; ③Add 20kg of OP-10 and stir until it dissolves; ④Add 20kg of diisooctyl sodium sulfosuccinate Stir to dissolve evenly; ⑤Finally add 20kg of alpha olefin sulfonate and stir until the solution is uniform.

[0054] Spacer fluid (prepared 1000kg):

[0055] ①Prepare 968kg of hydrochloric acid with a concentration of 15% by weight in an acid tank with a stirring device; ②Add 10kg of cetylpyridinium chloride under continuous stirring; ③Add 20kg of polyepoxysuccinic acid and stir until it dissolves; ④Add 2kg of cinnamaldehyde, stirring constantly, until the cinnamaldehyde dissolves evenly.

[0056] Cleaning solution (prepared 1000kg):

[0057] ①Add 596kg of distilled water to a conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com