Additive manufacturing method for light shielding body with multi-ray shielding and self-generating functions

A ray shielding and additive manufacturing technology, applied in the direction of additive processing of liquid materials, obtaining electrical energy from radioactive sources, shielding, etc., can solve the problems of cumbersome structure, lack of flexibility, etc., to improve efficiency, ensure mechanical stability, and facilitate The effect of detection and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

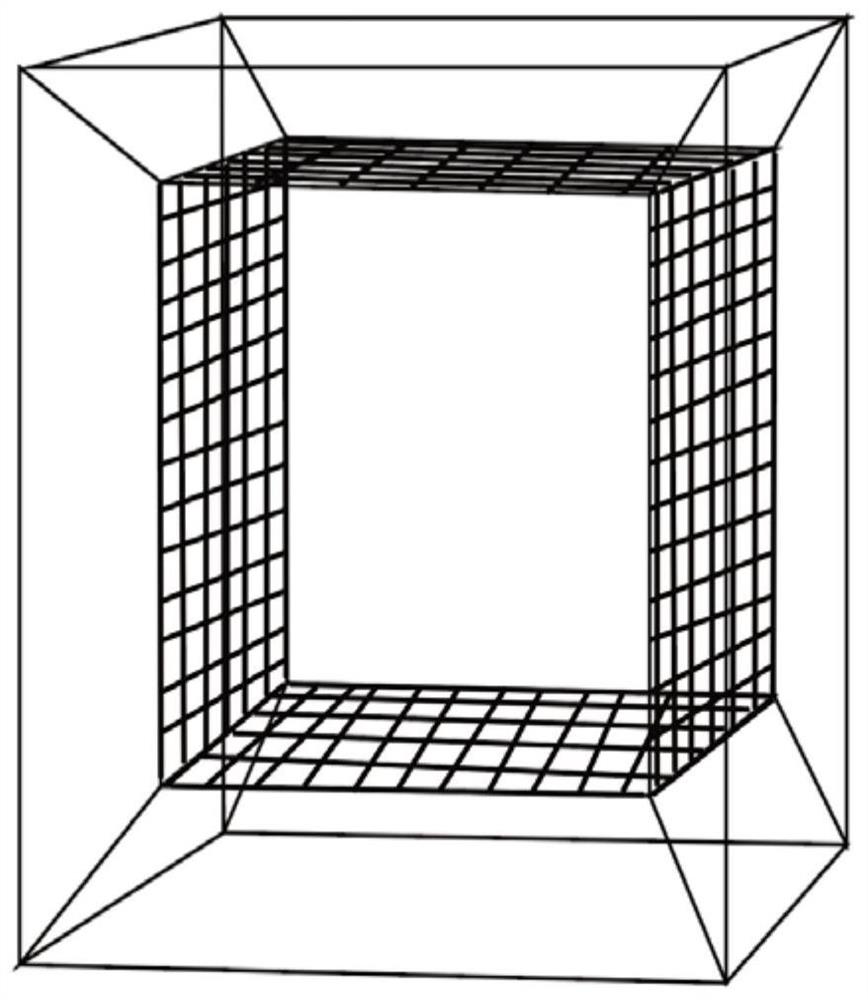

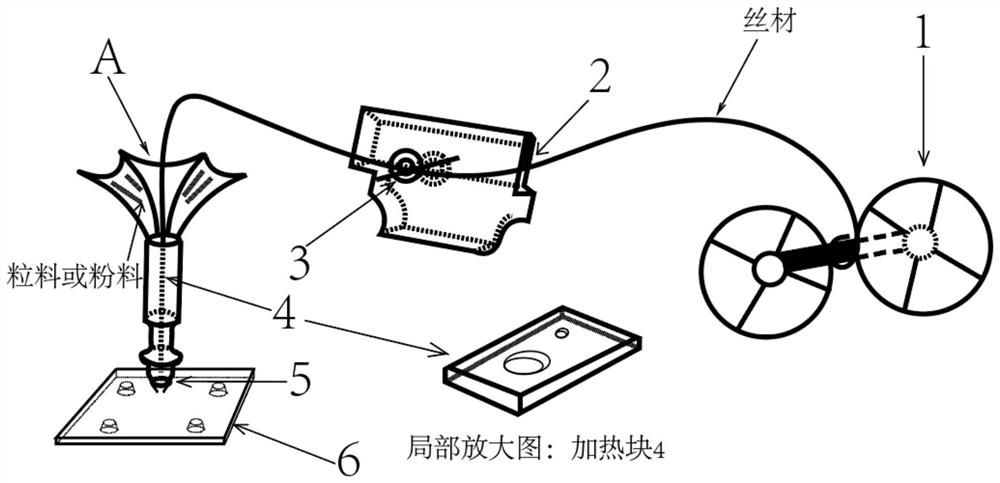

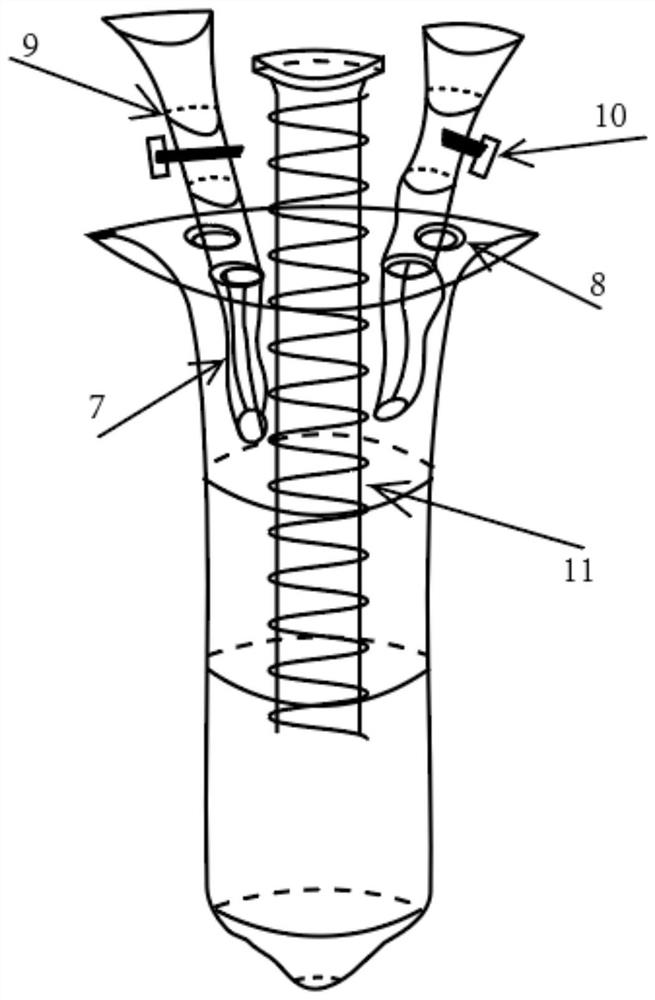

[0031] The invention provides a lightweight shielding body additive manufacturing method with multi-ray shielding and self-generating functions. In this method, the three-dimensional matrix skeleton is firstly modeled with the help of three-dimensional modeling software. Then analyze and optimize through the finite element engineering analysis software, while ensuring the mechanical performance requirements of the overall structure, determine the spatial position distribution of the skeleton, the diameter of the skeleton, and the direction of the support. Then set multiple groups of filling schemes for various nuclear ray shielding materials outside the skeleton, and obtain the optimal mass ratio, spatial position distribution, and spatial thickness distribution of various nuclear ray shielding materials outside the skeleton through simulation and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com