JT throttling refrigerating machine gas coupled with regenerative refrigerating machine

A technology of throttling refrigerators and refrigerators, applied in refrigerators, gas cycle refrigerators, refrigeration and liquefaction, etc., can solve the problems of increasing the difficulty and uncertainty of the optimization design of the whole machine, and the unclear thermal coupling mechanism, etc., to achieve Effects of eliminating heat transfer loss, reducing weight and volume, and streamlining components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

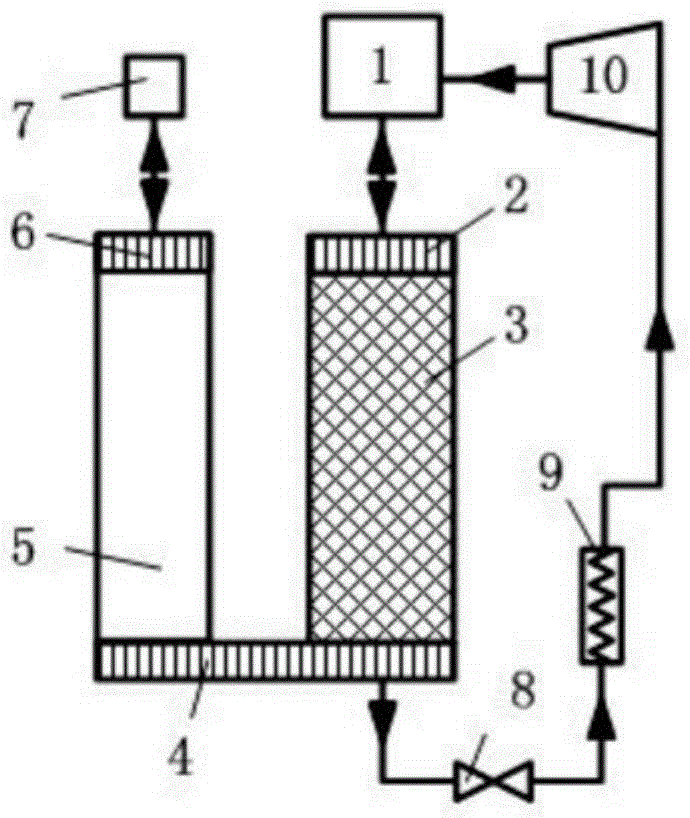

[0033] like figure 1 As shown, a JT throttling refrigerator air-coupled with the regenerative refrigerator includes two parts: the regenerative refrigerator and the JT throttling refrigeration assembly drawn from the regenerative refrigerator. Tube refrigerator; regenerative refrigerator includes regenerative refrigerator compression device 1, regenerator hot-end heat exchanger 2, regenerator 3, regenerative refrigerator cold-end heat exchanger 4, pulse tube 5, The pulse tube hot end heat exchanger 6 and the phase adjustment mechanism 7; the JT throttling refrigeration assembly includes a throttle valve 8, a throttling refrigeration assembly cold end heat exchanger 9 and a JT compressor 10.

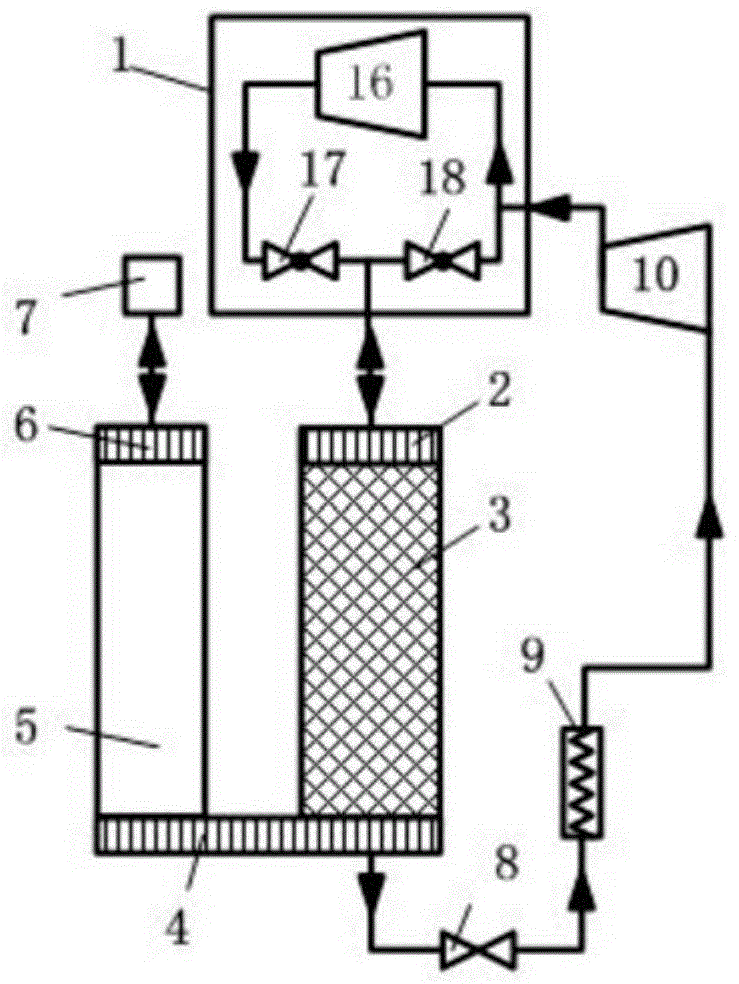

[0034] like figure 2 As shown, the regenerative refrigerator is a GM pulse tube refrigerator, and the compression device 1 of the regenerative refrigerator is composed of a scroll compressor 16 , a high-pressure control valve 17 and a low-pressure control valve 18 .

[0035] The connec...

Embodiment 2

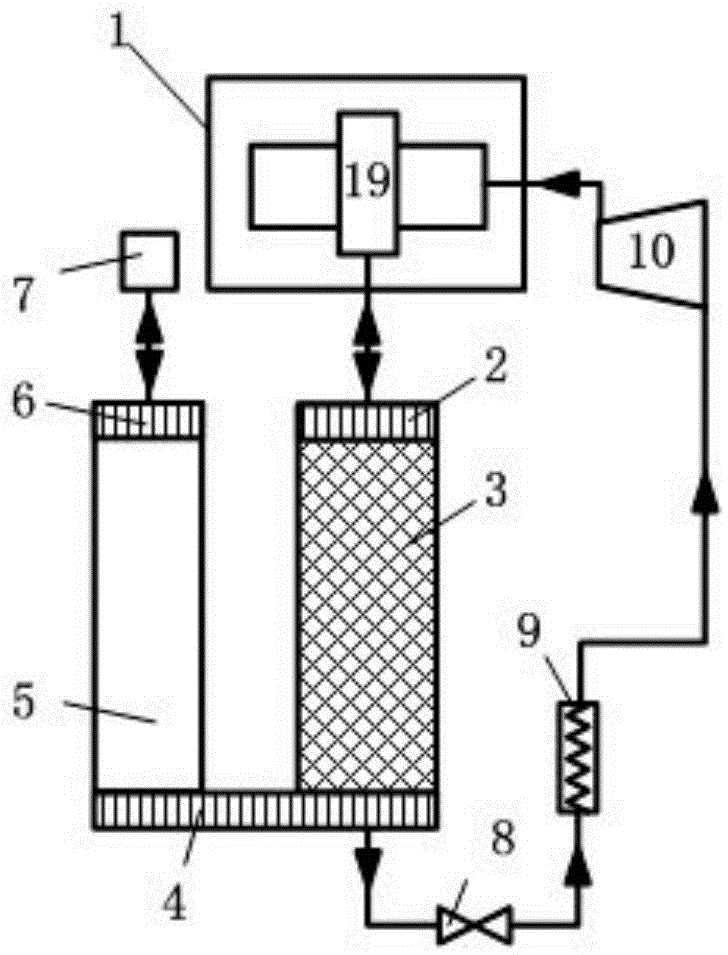

[0040] Such as image 3 As shown, a JT throttling refrigerator air-coupled with a regenerative refrigerator has the same structure as figure 1 The refrigerators shown are basically the same in structure, the difference is that the regenerative refrigerator is a Stirling type pulse tube refrigerator, and the compression device 1 of the regenerative refrigerator is composed of a linear compressor 19 .

[0041] The connections between the components are:

[0042] The compression chamber of the linear compressor 19 communicates with the heat exchanger 2 of the regenerator through a pipeline, the back pressure chamber of the linear compressor 19 communicates with the outlet of the JT compressor 10 through a pipeline, and the hot end heat exchanger 2 of the regenerator, The regenerator 3, the cold-end heat exchanger 4 of the regenerative refrigerator, the pulse tube 5, the hot-end heat exchanger 6 of the pulse tube, and the phase adjustment mechanism 7 are connected in sequence, an...

Embodiment 3

[0046] Such as Figure 4 As shown, a regenerative refrigerator air-coupled JT throttling refrigerator has the same structure as figure 1 The structures of the refrigerators shown are basically the same, the difference being that the JT throttling refrigeration assembly includes a partition wall heat exchanger 11 for accumulating the JT throttling refrigeration effect to obtain a lower refrigeration temperature.

[0047] The connection method of each part is as follows:

[0048] Compression device of recuperative refrigerator 1, regenerator hot end heat exchanger 2, regenerator 3, regenerative refrigerator cold end heat exchanger 4, pulse tube 5, pulse tube hot end heat exchanger 6 and regulator The phase mechanism 7 is connected in turn;

[0049] According to the flow direction of the working fluid, the outlet of the cold-end heat exchanger 4 of the regenerative refrigerator passes through the high-pressure side pipeline of the partition wall heat exchanger 11, the throttle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com