High-frequency reciprocating reversing workbench and method for machining punch through high-frequency reciprocating reversing workbench

A technology of workbench and workbench, which is applied in the direction of metal processing equipment, manufacturing tools, grinding workpiece supports, etc., can solve the problems of low processing efficiency, achieve high processing efficiency, improve processing efficiency, and have strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

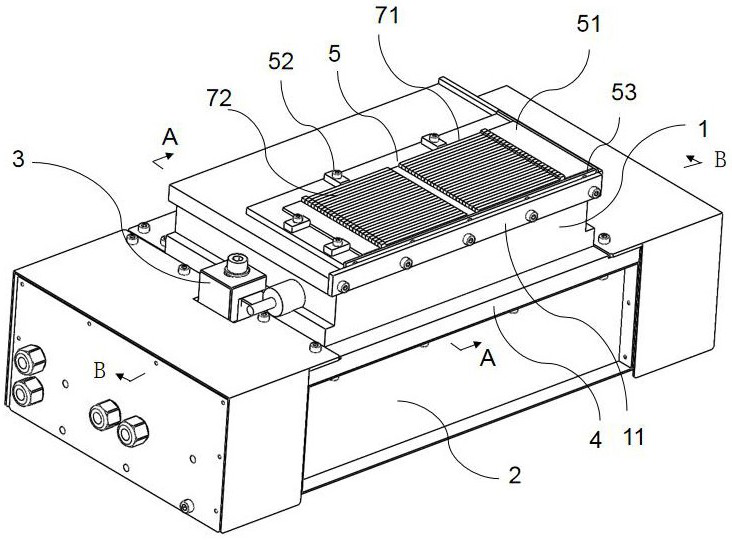

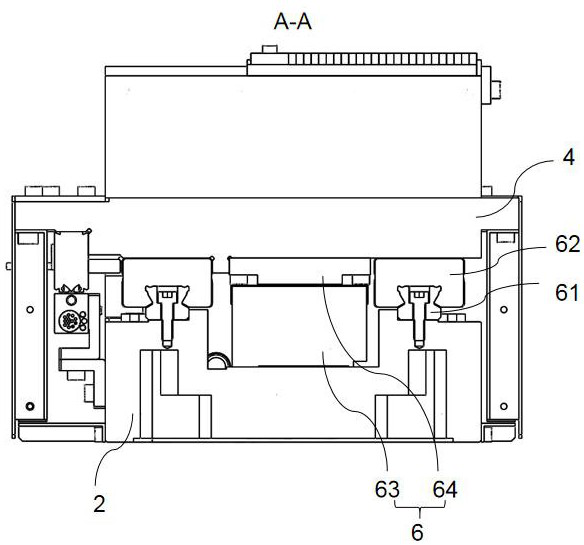

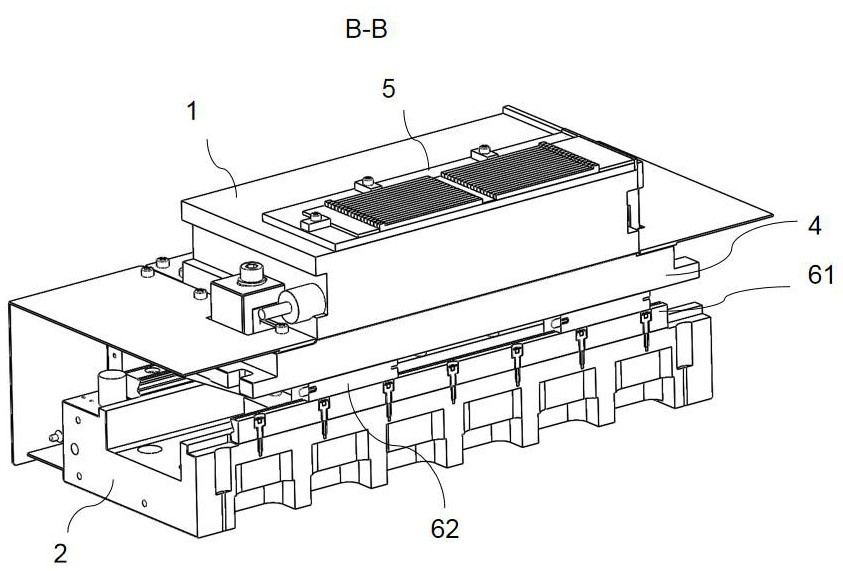

[0059] This embodiment provides a high-frequency reciprocating commutation workbench, such as Figure 1-3 As shown, it includes a magnetic table 1, a magnetic table installation base 2, a parts tray 5 and a reciprocating drive mechanism 6;

[0060] Wherein, the magnetic table 1 is fixedly connected to the slider 62, the magnetic table installation base 2 is fixedly connected to the linear guide rail 61, and the slider 62 is slidably connected to the linear guide rail 61;

[0061] The reciprocating drive mechanism 6 drives the slide block 62 to slide on the linear guide rail 61;

[0062] The parts tray 5 can be fixed on the upper surface of the magnetic table 1 by magnetic force. Those skilled in the art know that the magnetic table 1 is a device that can generate magnetic force when it is energized, and the parts tray 5 can be fixed on the magnetic table 1 by magnetic force. surface, the parts tray 5 needs to be made of a material that can be attracted by the magnetic force o...

Embodiment 2

[0077] The present invention also provides a punch processing method, the steps of which are as follows: Figure 4-5 shown, including:

[0078] S10. Arranging a plurality of parts in a row on the parts tray 5 to form a first part row 71;

[0079] Now, the non-processed end of the part abuts against the parts tray baffle 53, and the parts are placed in sequence. Of course, a parts baffle 51 can be placed against the parts tray baffle 53 first, and then the parts are placed, so that Its unprocessed end abuts on the parts baffle 51; In the two opposite directions of the baffle plate 53, a connector is used to fix the fixed block on the parts tray 5, thereby completing the placing of the parts on the parts tray;

[0080] S20. Place the parts tray 5 on the magnetic table 1 of the high-frequency reciprocating reversing workbench as in Embodiment 1, magnetize the magnetic table 1, and fix the parts tray 5 and the magnetic table 1 by magnetic force;

[0081] Among them, the connect...

Embodiment 3

[0094] The difference between the third embodiment and the second embodiment is that the second embodiment processes one row of parts at a time, while the third embodiment processes two rows of parts at a time, such as Figure 7 shown.

[0095]Specifically, in step S10, two rows of parts are placed, respectively the first part row 71 and the second part row 72, such as figure 1 As shown, a part baffle 53 is arranged between the first part row 71 and the second part row 72; the first part row 71 and the second part row 72 are symmetrically arranged, and the ends to be processed are oppositely arranged.

[0096] Thus, during processing, such as Figure 7 As shown, the grinding wheel rotates at a fixed position, only the up and down feed is adjusted, and the parts follow the high-frequency reciprocating reversing table to reciprocate in the horizontal direction and perpendicular to the axis of the grinding wheel, thereby completing the processing of the parts by the grinding whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com