Fluorite ore beneficiation method

A beneficiation method and fluorite ore technology, applied in the field of fluorite ore beneficiation, can solve problems such as difficult removal, difficult separation, high concentrate content, etc., and achieve the effects of reducing drug costs, improving beneficiation quality, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

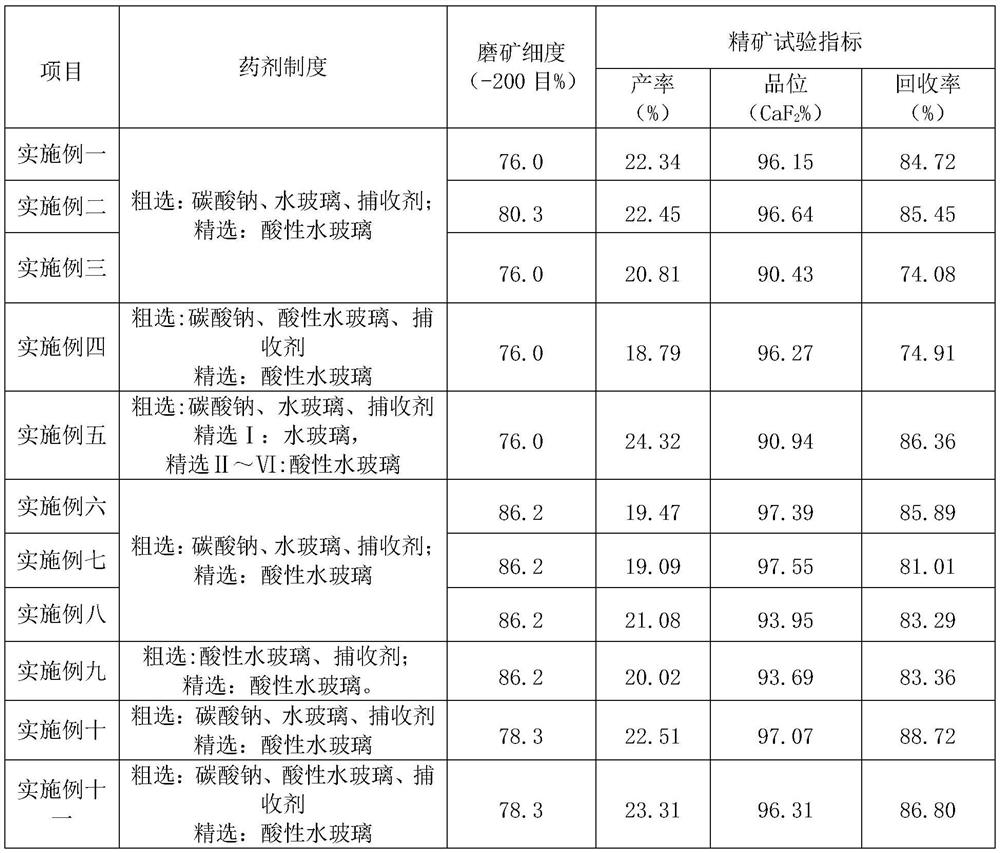

Embodiment 1

[0036] The embodiments of the present application disclose a method for beneficiation of fluorite ore. The mass percentage component of fluorite ore in this example is CaF 2 Content 25.40%, CaCO 3 Content 6.85%, MgO content 2.06%, SiO 2 The content is 62.31%, the balance is impurities, CaF 2 The content is low, the fine-grained content of the ore is high, and the fine-grained gangue of the ore is not easy to come out, so it belongs to the refractory fluorite ore.

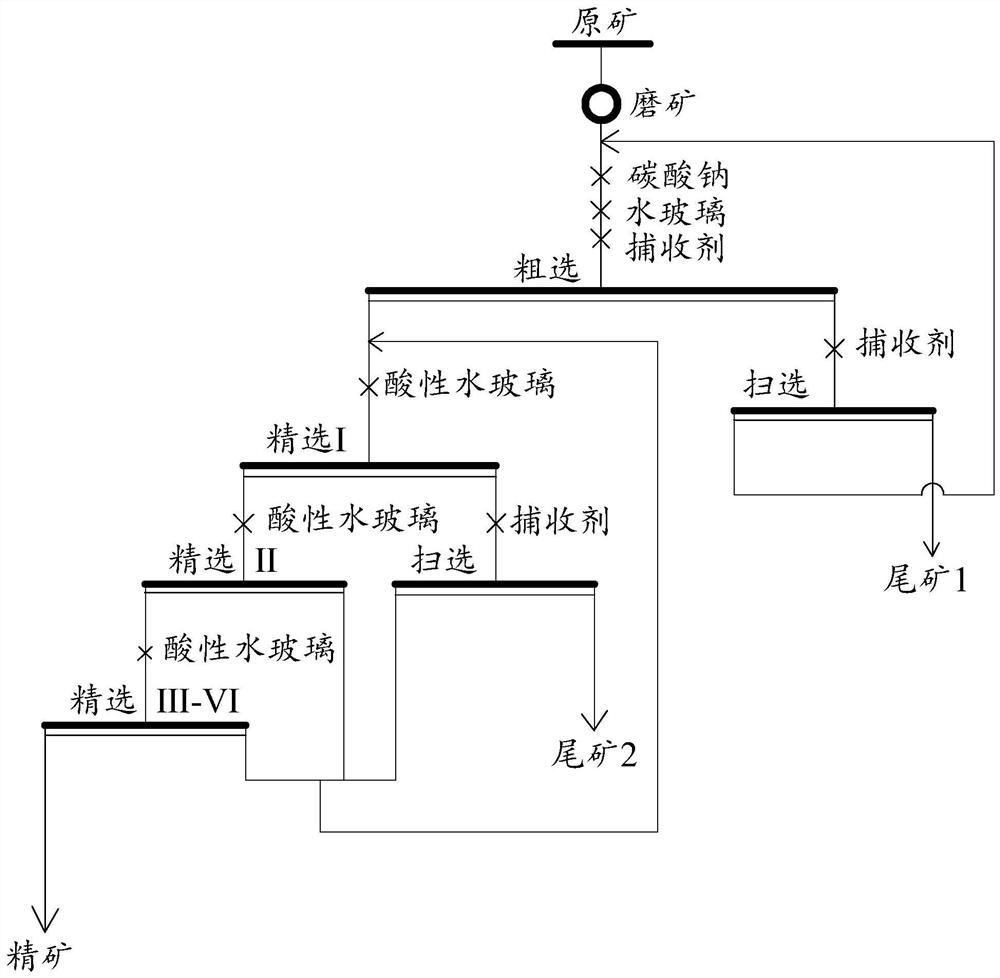

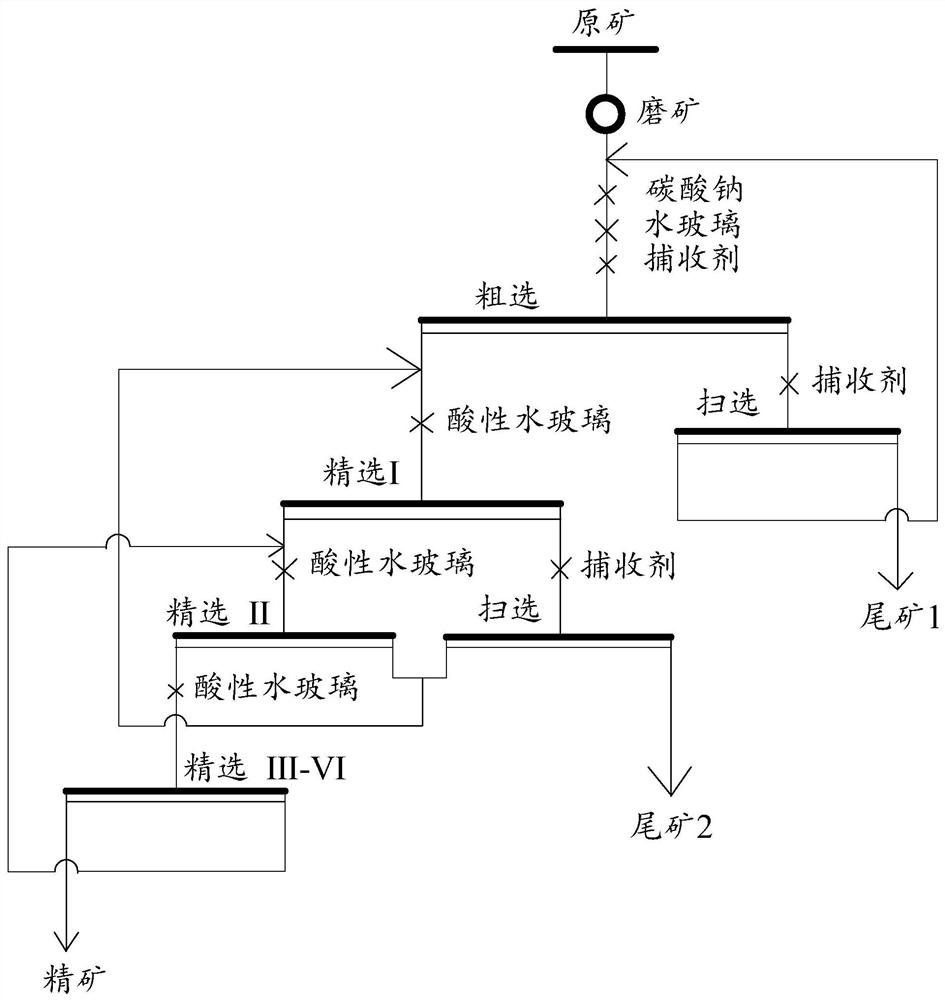

[0037] refer to figure 1 , fluorite beneficiation methods include:

[0038] (1) Roughing: The first choice is to grind the raw fluorite ore after pulverizing, and grind until the fineness of the ore powder is less than 200 mesh and the content accounts for 76.0%.

[0039] The roughing operation adopts alkaline medium flotation. Sodium carbonate, water glass and collector are successively added to the pulp for roughing to obtain fluorite roughing concentrate and roughing tailings. Sodium carbonate, water glass...

Embodiment 2

[0045] The embodiments of the present application disclose a method for beneficiation of fluorite ore. The mass percentage component of fluorite ore in this example is CaF 2 Content 25.40%, CaCO 3 Content 6.85%, MgO content 2.06%, SiO 2 The content is 62.31%, the balance is impurities, CaF 2 The content is low, the fine-grained content of the ore is high, and the fine-grained gangue of the ore is not easy to come out, so it belongs to the refractory fluorite ore.

[0046] refer to figure 1 , fluorite beneficiation methods include:

[0047] (1) Roughing: The first choice is to grind the raw fluorite ore after crushing, and grind to the point where the fineness of the ore powder is less than 200 mesh and the content accounts for 80.3%.

[0048] The roughing operation adopts alkaline medium flotation. Sodium carbonate, water glass and collector are successively added to the pulp for roughing to obtain fluorite roughing concentrate and roughing tailings. Sodium carbonate, w...

Embodiment 3

[0054] The embodiments of the present application disclose a method for beneficiation of fluorite ore. The mass percentage component of fluorite ore in this example is CaF 2 Content 25.40%, CaCO 3 Content 6.85%, MgO content 2.06%, SiO 2 The content is 62.31%, the balance is impurities, CaF 2 The content is low, the fine-grained content of the ore is high, and the fine-grained gangue of the ore is not easy to come out, so it belongs to the refractory fluorite ore.

[0055] The beneficiation methods of fluorite ore include:

[0056] (1) Roughing: The first choice is to grind the raw fluorite ore after pulverizing, and grind until the fineness of the ore powder is less than 200 mesh and the content accounts for 76.0%.

[0057] The roughing operation adopts alkaline medium flotation. Sodium carbonate, water glass and collector are successively added to the pulp for roughing to obtain fluorite roughing concentrate and roughing tailings. Sodium carbonate, water glass and colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com