Carbon-based cobalt-palladium bimetallic nano-catalyst and preparation and application thereof

A bimetallic nanometer, carbon-based cobalt-palladium technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, hydrocarbon production from carbon oxides, etc., can solve the problem of high temperature sintering of metal nanoparticles and carbon dioxide Deposition, high cost, difficult to apply to industrial production on a large scale, etc., to achieve excellent catalytic performance, improved utilization, and reduced reaction temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

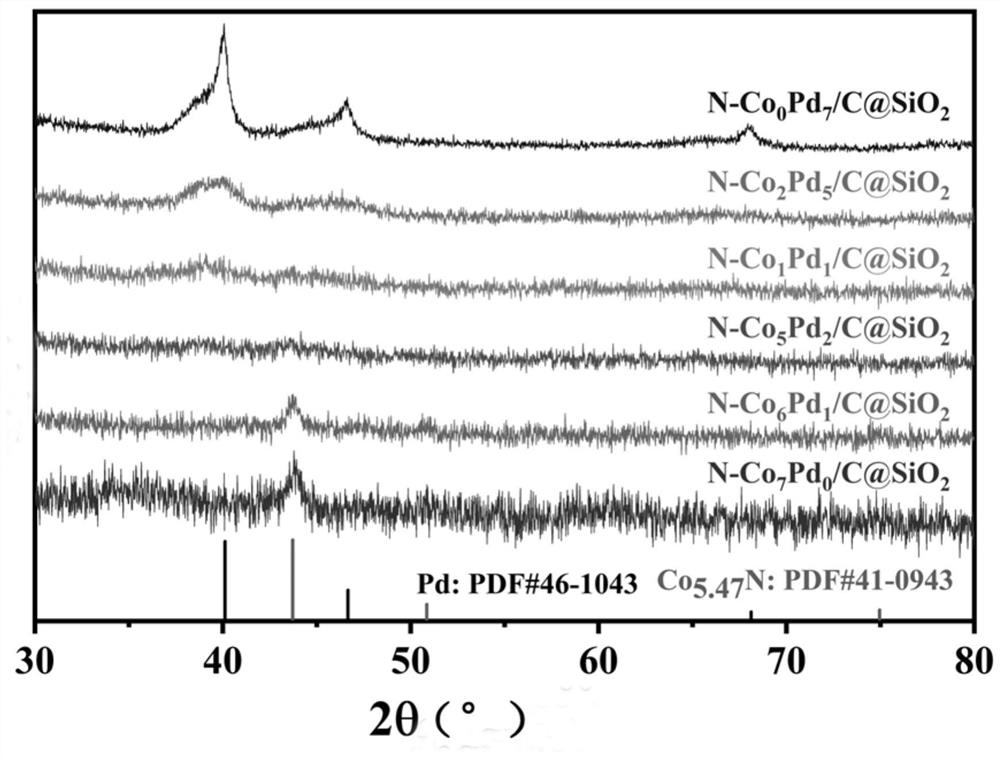

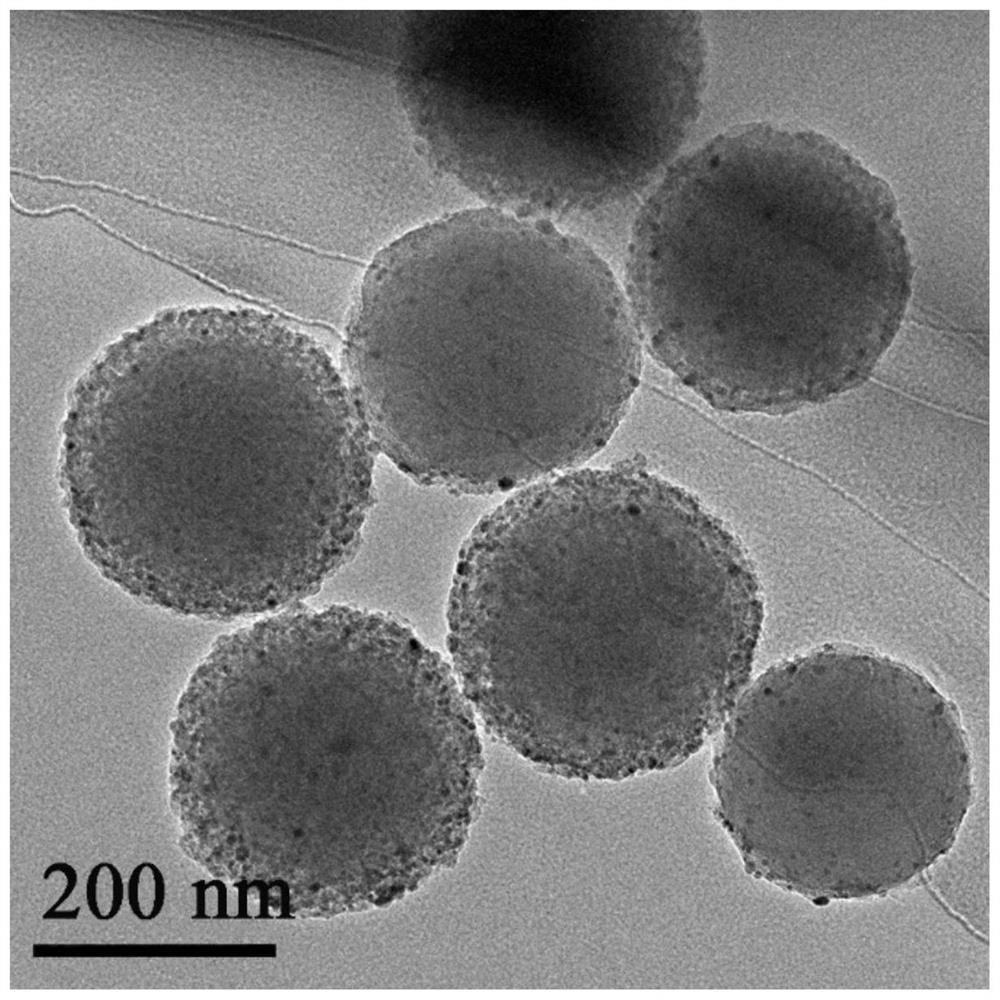

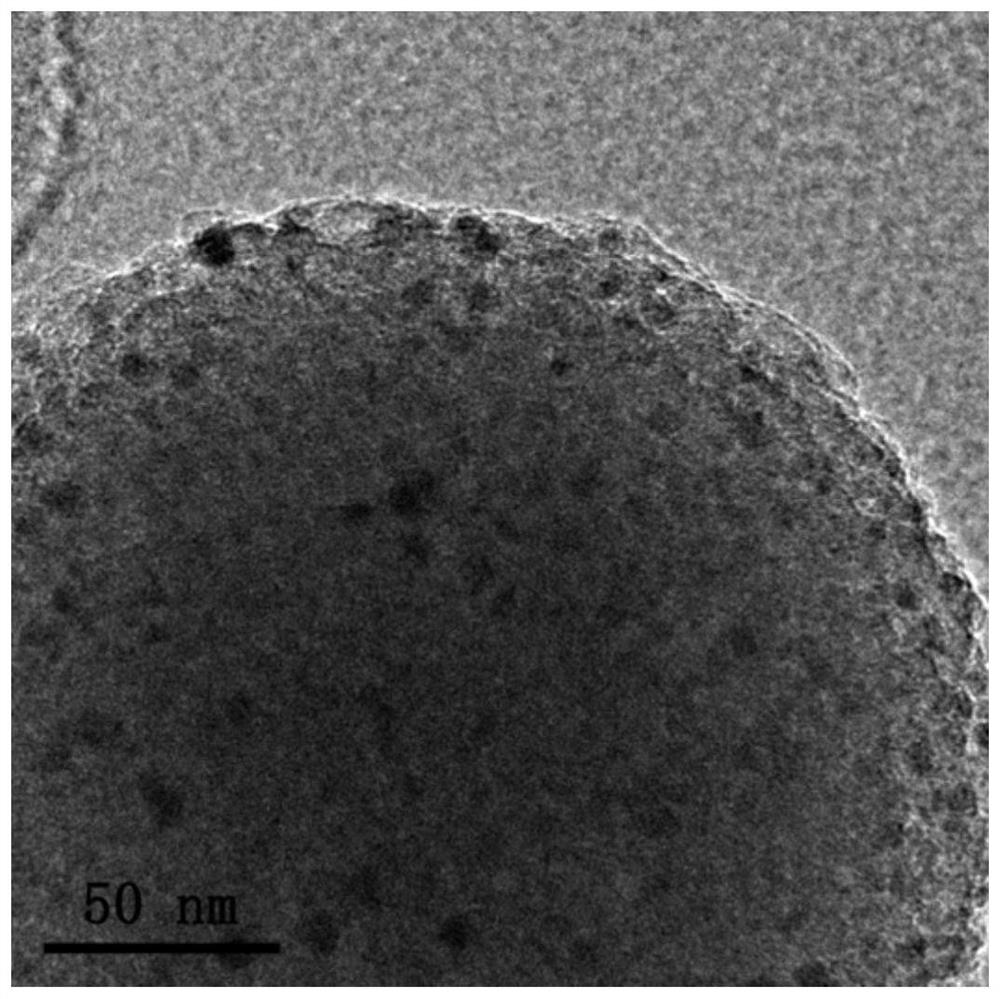

[0064] N-Co x PD y / C@SiO 2 Catalyst preparation

[0065] (1) Take 70 mL of ethanol and 10 mL of deionized water to make a mixed solution, and add 5 mL of ammonia water to the mixed solution dropwise. After stirring on a stirrer for 30 minutes, 5 mL of tetraethylorthosilicate was added dropwise.

[0066] (2) The mixed solution in step (1) was vigorously stirred for 45 minutes, and then a mixed solution of tetraethylorthosilicate (1.8 mL) and octadecyltrimethoxysilane (0.8 mL) was added dropwise. Stirring was continued for 10 minutes, then allowed to stand for 3 hours to fully hydrolyze.

[0067] (3) The mixture obtained in step (2) was centrifuged, and the lower precipitate was washed with distilled water and ethanol three times respectively, and then dried in an oven at 60° C. overnight.

[0068] (4) The dried product obtained in step (3) was calcined in air at 550° C. (heating rate 3° C. / min) for 6 h to obtain silica nanospheres.

[0069] (5) Dissolve the silica nanosp...

Embodiment 2

[0081] N-Co x PD y / SiO 2 Catalyst preparation

[0082] (1) Take 70 mL of ethanol and 10 mL of deionized water to make a mixed solution, and add 5 mL of ammonia water to the mixed solution dropwise. After stirring on a stirrer for 30 minutes, 5 mL of tetraethylorthosilicate was added dropwise.

[0083](2) The mixed solution in step (1) was vigorously stirred for 45 minutes, and then a mixed solution of tetraethylorthosilicate (1.8 mL) and octadecyltrimethoxysilane (0.8 mL) was added dropwise. Stirring was continued for 10 minutes, then allowed to stand for 3 hours to fully hydrolyze.

[0084] (3) The mixture obtained in step (2) was centrifuged, and the lower precipitate was washed with distilled water and ethanol three times respectively, and then dried in an oven at 60° C. overnight.

[0085] (4) The dried product obtained in step (3) was calcined in air at 550° C. (heating rate 3° C. / min) for 6 h to obtain silica nanospheres.

[0086] (5) Dissolve the silica nanospher...

Embodiment 3

[0091] N-Co x PD y / C@SiO 2 Catalysts for photothermal catalysis of CO 2 Reduction experiment

[0092] N-Co x PD y / C@SiO 2 Catalyst (10 mg) was ultrasonically treated with 0.5 mL of water for 20 min, and dispersed evenly on a quartz disc with a diameter of 4 cm. Then the quartz disc was placed in a stainless steel reactor with CO 2 :H 2 = 1:4 stoichiometric mixed gas fills the reactor multiple times, with a total pressure of 0.1 MPa. With a 300W xenon lamp as the light source, the auxiliary heating system controls the reaction temperature to 220°C. The temperature is precisely monitored by thermocouples in close contact with the quartz plate. The catalytic reaction was carried out for 6 hours, in which the temperature was raised from room temperature to 220°C in the first hour, and the temperature was maintained at 220°C for the next 5 hours. The catalytic products were quantitatively analyzed by gas chromatography (GC-2014C, Shimadzu). Its catalytic performance is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com