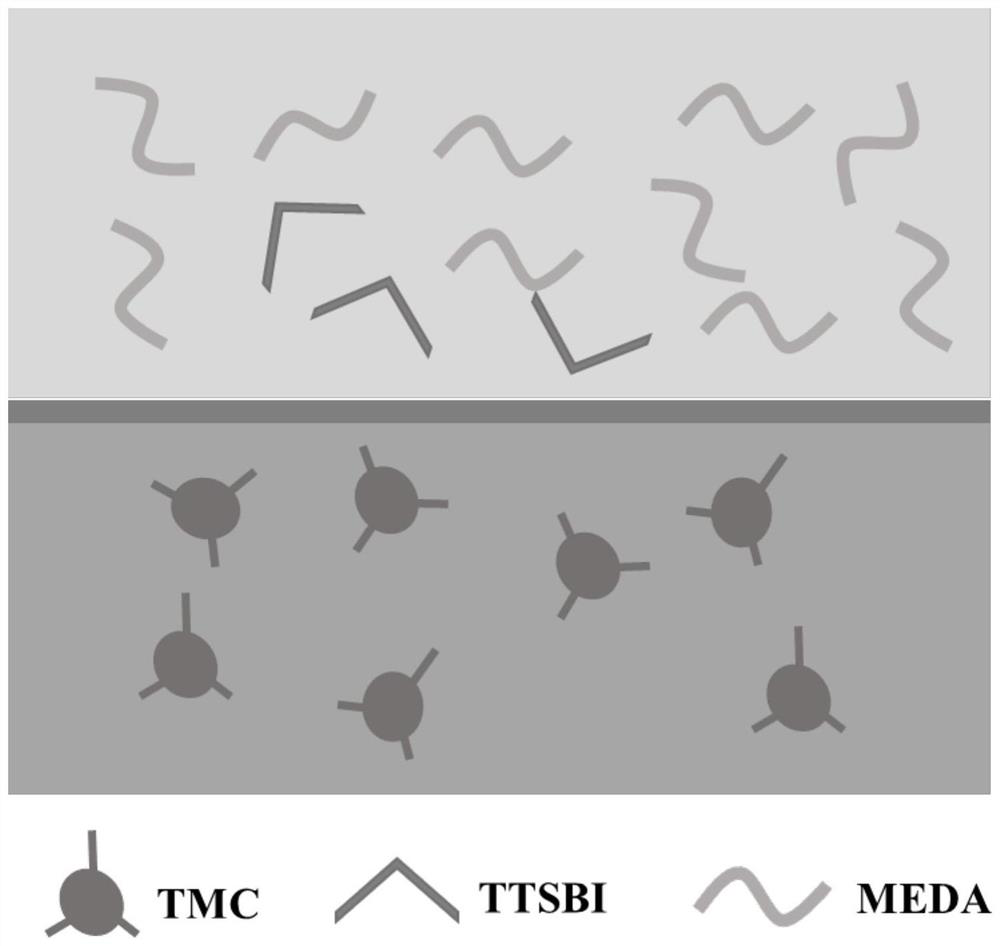

Method for preparing high-performance carbon dioxide separation composite membrane containing twisted structure through interfacial polymerization

A technology of interfacial polymerization and twisted structure, applied in separation methods, chemical instruments and methods, semi-permeable membrane separation, etc., can solve problems such as unfavorable gas transmission, and achieve excellent selectivity, easy amplification, and improved selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Preparation of separation layer solution: dissolve trimesoyl chloride in n-heptane and stir to form a uniform oil phase solution, the concentration of trimesoyl chloride solution is 0.01mol / L; N-methyldiethanolamine and 5, 5′,6,6′-Tetrahydroxy-3,3,3′,3′-Tetramethyl-spirobisindene was dissolved in deionized water, and sodium carbonate was added to stir to form an aqueous phase solution, N-methyldiethanolamine The concentration is 0.03mol / L, and the molar ratio of 5,5′,6,6′-tetrahydroxy-3,3,3′,3′-tetramethyl-spirobisindene to methyldiethanolamine is 0.05:1 , using sodium carbonate to adjust the pH of the solution to 10.5.

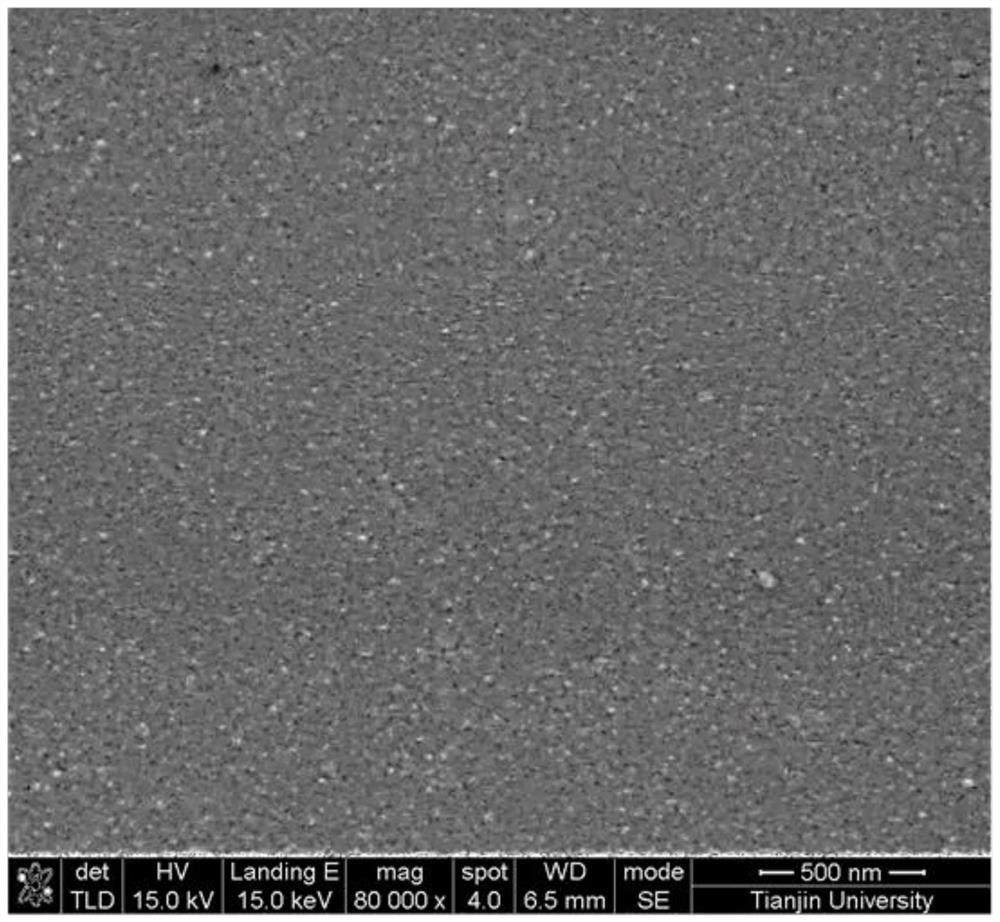

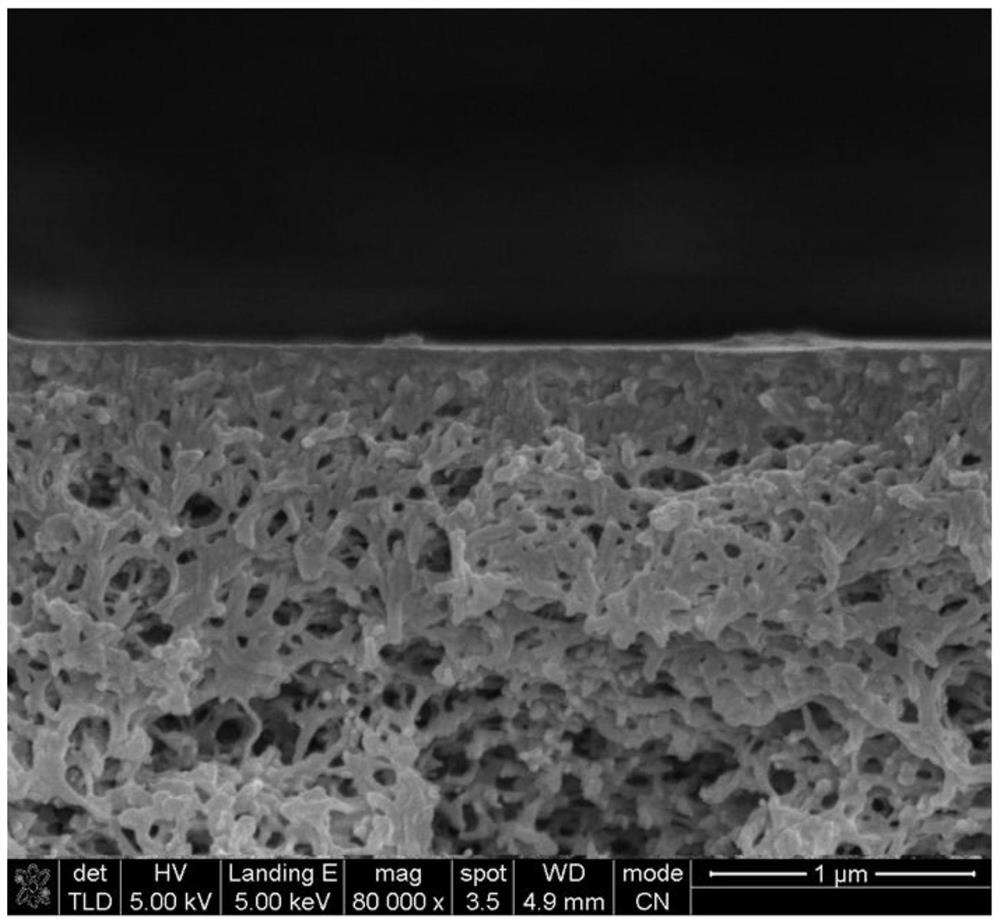

[0034] (2) Composite membrane preparation: fix the polysulfone ultrafiltration membrane coated with the middle layer on the plate frame, pour the oil phase solution, after the oil phase solution fully infiltrates the middle layer, pour out the oil phase and dry it, then pour water Phase solution, reacted at 40 °C for 10 minutes by interfacial poly...

Embodiment 2

[0037] (1) Preparation of separation layer solution: dissolve trimesoyl chloride in n-heptane and stir to form a uniform oil phase solution, the concentration of trimesoyl chloride solution is 0.015mol / L; N-methyldiethanolamine and 5, 5′,6,6′-Tetrahydroxy-3,3,3′,3′-Tetramethyl-spirobisindene was dissolved in deionized water, and sodium carbonate was added to stir to form an aqueous phase solution, N-methyldiethanolamine The concentration is 0.06mol / L, and the molar ratio of 5,5′,6,6′-tetrahydroxy-3,3,3′,3′-tetramethyl-spirobisindene to N-methyldiethanolamine is 0.05 : 1, using sodium carbonate to adjust the pH of the solution to be 10.

[0038] (2) Composite membrane preparation: fix the polyacrylonitrile ultrafiltration membrane coated with the middle layer on the plate frame, pour the oil phase solution, the oil phase solution fully infiltrates the middle layer, pour out the oil phase and dry it, and then pour it into The aqueous phase solution was reacted at 40 °C for 15 m...

Embodiment 3

[0041] (1) Preparation of separation layer solution: dissolve trimesoyl chloride in n-heptane and stir to form a uniform oil phase solution, the concentration of trimesoyl chloride solution is 0.015mol / L; N-methyldiethanolamine and 5, 5′,6,6′-Tetrahydroxy-3,3,3′,3′-Tetramethyl-spirobisindene was dissolved in deionized water, and sodium carbonate was added to stir to form an aqueous phase solution, N-methyldiethanolamine The concentration is 0.12mol / L, and the molar ratio of 5,5′,6,6′-tetrahydroxy-3,3,3′,3′-tetramethyl-spirobisindene to N-methyldiethanolamine is 0.5 : 1, using sodium carbonate to adjust the pH of the solution to be 10.5.

[0042] (2) Composite membrane preparation: Fix the polyethersulfone ultrafiltration membrane coated with the middle layer on the plate frame, pour the oil phase solution, the oil phase solution fully infiltrates the middle layer, pour out the oil phase and dry it, and then pour it into The aqueous phase solution was reacted at 30 °C for 3 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com