Nickel-supported hydrophobic SiO2 composite film and production method thereof

A loaded, hydrophobic technology, applied in separation methods, chemical instruments and methods, membranes, etc., can solve problems such as poor hydrothermal stability, and achieve improved hydrothermal stability, increased permeation rate, and improved water vapor stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

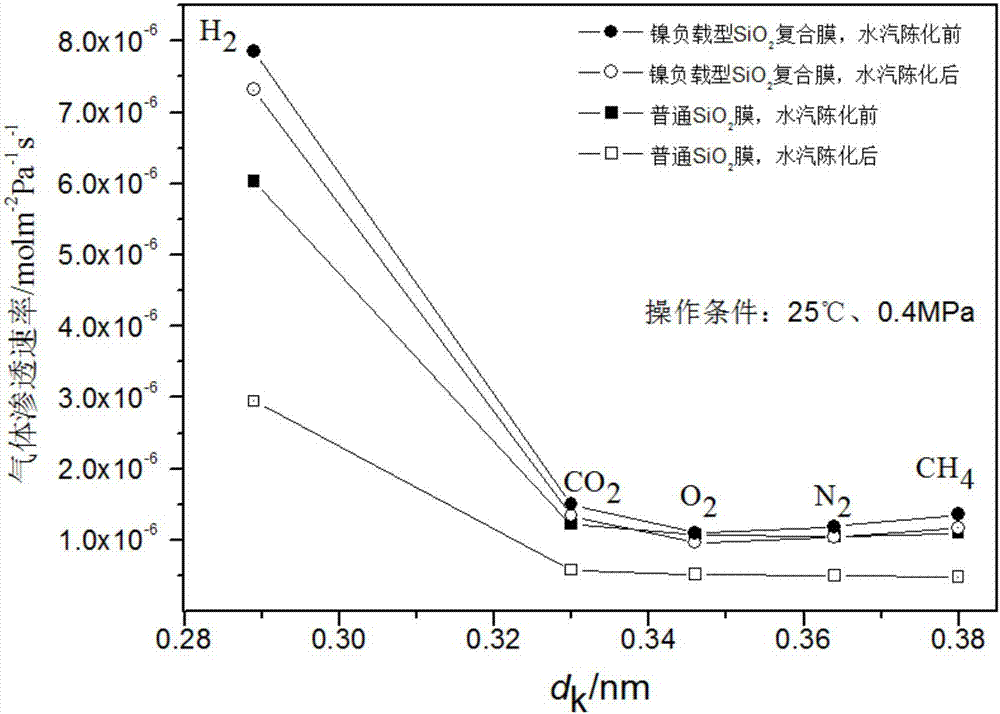

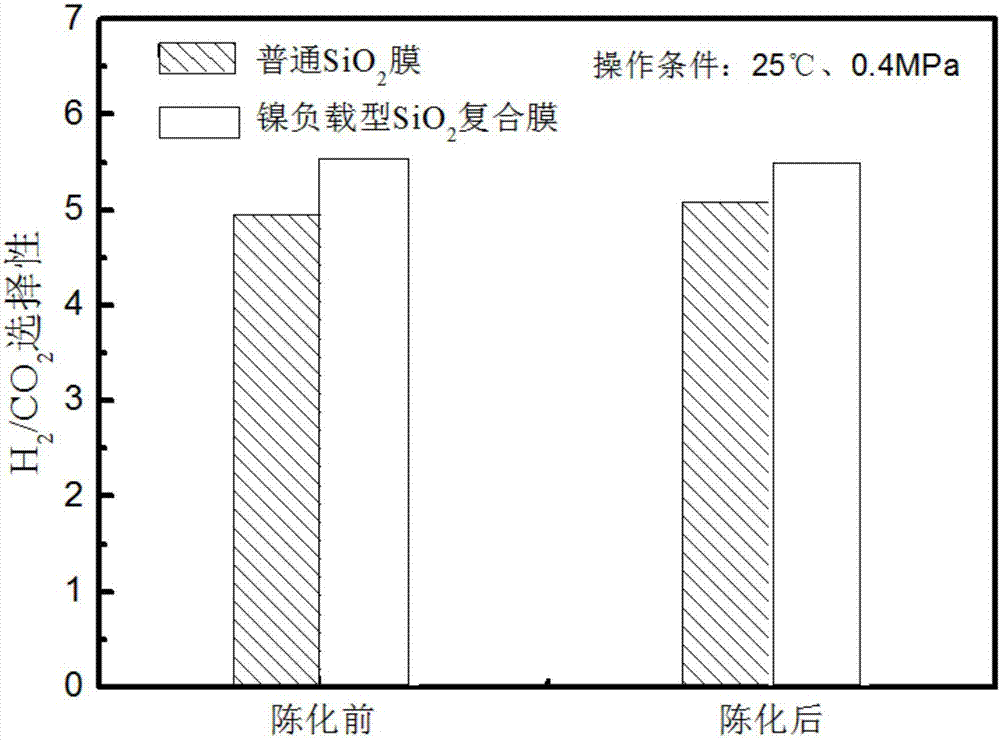

[0037] Nickel-loaded hydrophobic SiO prepared by the preparation method of the present invention 2 Composite film, in the enhanced SiO 2 Based on the water vapor stability of the membrane, the H 2 The permeation rate and H 2 / CO 2 Separation factor, after aging in a water vapor environment, H 2 Permeation rate decreased only slightly, H 2 / CO 2 On the contrary, the separation factor increases, and the hydrothermal stability is effectively improved.

[0038] A kind of nickel-loaded hydrophobic SiO of the present invention 2 The effect of each component that adds in the preparation method of composite film: tetraethyl orthosilicate (TEOS) is as silicon source; Methyltriethoxysilane (MTES) is as hydrophobic modifier, replaces part tetraethyl orthosilicate, Preparation of methyl-modified SiO by cohydrolytic condensation reaction of both 2 film; absolute ethanol (EtOH) was used as a solvent on the one hand, and also a product of polycondensation reaction on the other hand; ...

Embodiment 1

[0042] Step 1, take the following components respectively according to mass percentage:

[0043] Tetraethyl orthosilicate 24.12%, methyltriethoxysilane 16.72%, absolute ethanol 41.63%, water 15.21%, HNO 3 0.63%, Ni(NO 3 ) 2 ·6H 2 O 1.68%, the sum of the mass percentages of the above components is 100%;

[0044] Step 2. Stir vigorously the ethyl orthosilicate, methyltriethoxysilane, and absolute ethanol weighed in step 1 in an ice-water bath for 45 minutes to mix them evenly to prepare a mixed solution;

[0045] Step 3, add dropwise the water weighed in step 1, dilute HNO to the mixed solution obtained in step 2 while stirring 3 and Ni(NO 3 ) 2 ·6H 2 The homogeneous mixed solution prepared by O solid was stirred and refluxed at 50 °C for 5 h after the dropwise addition, and cooled naturally to room temperature to obtain the original Ni / SiO 2 Sol;

[0046] Step 4, add the mixture of drying control agent and absolute ethanol to the original Ni / SiO in step 3 while stirri...

Embodiment 2

[0050] Step 1, take the following components respectively according to mass percentage:

[0051] Tetraethyl orthosilicate 22.41%, methyltriethoxysilane 16.30%, absolute ethanol 42.69%, water 15.49%, HNO 3 0.61%, Ni(NO 3 ) 2 ·6H 2 O 2.50%, the sum of the mass percentages of the above components is 100%;

[0052] Step 2. Stir vigorously the ethyl orthosilicate, methyltriethoxysilane, and absolute ethanol weighed in step 1 in an ice-water bath for 45 minutes to mix them evenly to prepare a mixed solution;

[0053] Step 3, add dropwise the water weighed in step 1, dilute HNO to the mixed solution obtained in step 2 while stirring 3 and Ni(NO 3 ) 2 ·6H 2 The homogeneous mixed solution prepared by O solid was stirred and refluxed at 60 °C for 3 h after the dropwise addition, and cooled naturally to room temperature to obtain the original Ni / SiO 2 Sol;

[0054] Step 4, add the mixture of drying control agent and absolute ethanol to the original Ni / SiO in step 3 while stirri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com