Flue gas denitration ammonia spraying mixing system and static mixer and ammonia spraying control method thereof

A static mixer and mixing system technology, applied in the field of flue gas denitrification, can solve the problems of large concentration gap, poor uniformity of ammonia injection, difficult to reflect truthfully, etc., and achieve the effects of increasing particle size, prolonging service life and avoiding wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

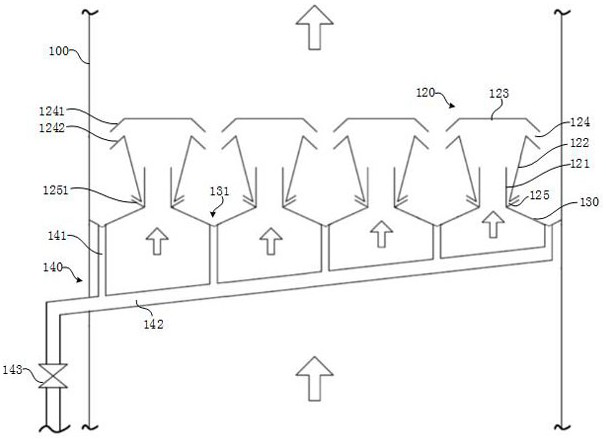

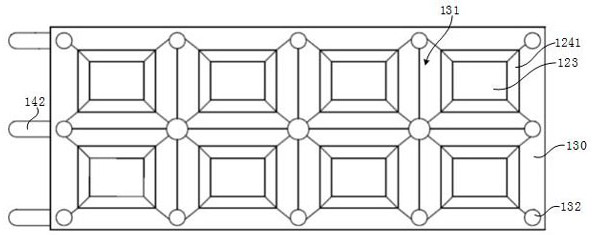

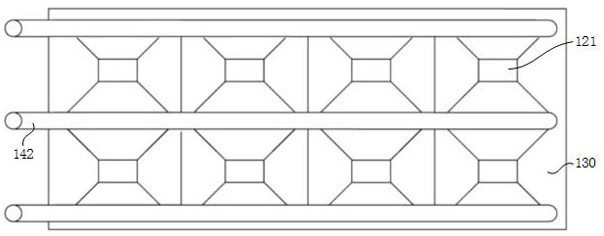

[0084] refer to Figure 1~3 As shown, the static mixer of the present embodiment is a single layer, which includes eight guide assemblies 120, and the guide assembly 120 consists of an air inlet pipe 121, an outer pipe 122, a top plate 123, four upper wing plates 1241 and four lower wings. Board 1242 composition. The air intake pipe 121 is a straight pipe, the cross section of the outer pipe 122 is rectangular, and the upper wing plate 1241 and the lower wing plate 1242 are trapezoidal. The dust discharge hole 125 communicates with an upwardly inclined dust discharge pipe 1251 , and the lower end surface of the outlet of the dust discharge pipe 1251 is higher than the upper end surface of the dust discharge hole 125 . Ash collecting groove is V-shaped groove 131. In the ash discharge pipe 140, three rows of first vertical sections 141 are respectively connected to three discharge pipe sections 142 to discharge dust. An on-off valve 143 is provided for regular ash discharge....

Embodiment 2

[0087] refer to Figure 4~6 As shown, the static mixer of the present embodiment is a single layer, which includes thirty-two guide assemblies 220, and the guide assembly 220 is composed of an air inlet pipe 221, an outer pipe 222, a top plate 223, an upper wing plate 2241 and a lower wing plate 2242. composition. The air inlet pipe 221 is a variable-diameter round pipe with a thick bottom and a thin top. The cross section of the outer pipe 222 is circular, the top plate 223 is inverted conical, and the upper wing 2241 and the lower wing 2242 are truncated cones. The dust discharge hole 225 communicates with a downwardly inclined dust discharge pipe 2251 , and the outlet of the dust discharge pipe 2251 is provided with a first cover plate 2252 . The ash collecting trough is an arc groove 231, and the notch is provided with a windshield 2311, one end of the windshield 2311 is connected with the outer pipe 222, and the other end extends downwards, leaving a gap between the wind...

Embodiment 3

[0090] refer to Figure 7 As shown, the static mixer of the present embodiment has two layers, wherein the structure of the static mixer of the lower floor is the same as that of Example 2; the structure of the static mixer of the upper floor is basically the same as that of Example 1. The pipeline is changed from three rows of first vertical sections to five rows of first vertical sections, which are respectively connected with five discharge pipe sections. The discharge pipes on the upper layer and the lower layer are respectively connected to five second vertical sections 344 to discharge the dust, and the second vertical sections 344 are provided with a second cover plate 345 for automatic ash discharge.

[0091] The flue gas of a coal-fired boiler adopts the double-layer static mixer of this embodiment. Along the flow direction of the flue gas, the content of particulate matter (dust) before the static mixer is 2272mg / Nm 3 , the particle (dust) content after the static m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com